Differences Between Rotary and Flat Laser Marking

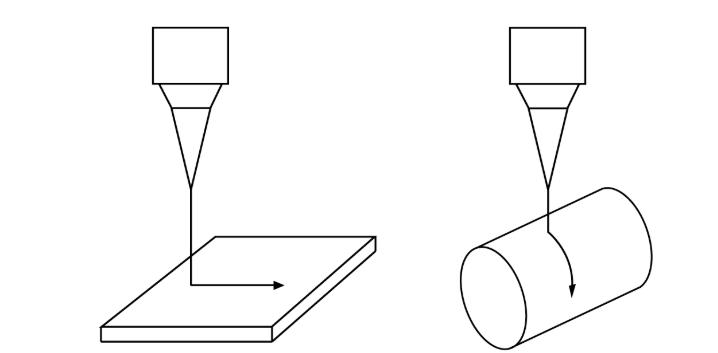

Rotary laser marking differs from flat laser marking mainly in the type of workpieces it processes.

Flat Laser Marking:

Primarily used for flat components such as nameplates or electronic parts. The laser focuses on a fixed plane and marks through XY-axis motion.Rotary Laser Marking:

Used for cylindrical or curved surfaces. The workpiece rotates while the laser maintains its focus on the midpoint of the curve, achieving consistent marking along the circular surface.

When marking around a cylindrical object, the laser focal distance changes due to surface curvature. This can lead to inconsistent energy density, uneven marking depth, and distorted patterns if not compensated properly.

Rotary Laser Marking in Industrial Applications

In the industrial marking field, rotary laser marking has become the mainstream solution for cylindrical and curved components. It allows 360° marking with no blind spots, providing high accuracy, excellent visual quality, and high production efficiency.

Challenges in Existing Marking Systems

Traditional marking systems use a galvo head combined with a rotary chuck to perform segmented marking. The process involves repeated cycles of “rotate → stop → mark.”

Although this approach ensures high precision within each segment, frequent start-stop motion reduces efficiency and cannot support continuous high-speed 360° marking.

Common issues include:

Delays in position synchronization

Laser output not matching rotational speed

Stitching misalignment, shadowing, and uneven energy distribution

These problems result in poor marking quality and low productivity.

Open-Loop Galvo Motion Control Solution

To overcome these challenges, the open-loop laser galvo motion controller enables synchronized rotation and galvo tracking using multi-axis linkage and PSO (Position Synchronized Output) technology.

Under this control architecture, the workpiece can complete 360° marking in continuous rotation without stopping or repositioning. The result is seamless pattern stitching, one-pass processing, and efficiency improvement by 3–5 times, with stitching errors less than 10 μm.

Through laser marking software integration, users can easily adjust laser power, scanning speed, and line spacing to control laser motion along the predesigned path. This allows both flat and curved surface marking without additional hardware changes, improving both marking quality and system performance while reducing development and integration costs.

Core Process Flow

The rotary flying laser marking solution converts the cylindrical surface into a flat coordinate plane through mathematical transformation. By synchronizing the galvo scanner and rotary axis, the system achieves continuous marking across the full 360° surface with high precision and zero overlap.

The system supports quick switching of processing parameters and DXF file import for new part configurations, enabling fast production setup.

Advantages of Rotary Flying Marking Control

Integrated Software and Hardware

Combines laser, galvo, and multi-axis control through industrial communication protocols, simplifying system architecture and reducing costs.High-Precision Galvo Calibration

Supports multi-point calibration and optional vision-based correction to ensure galvo positioning accuracy.Smart Path Optimization

Automatically calculates the shortest toolpath, minimizing idle motion and maximizing efficiency. Compatible with DXF, AI, SVG, and other vector formats.Advanced Graphic Editing

Supports vector, image, text, barcode, and pattern editing, enabling flexible design modification directly in the software.Rich Processing Modes

Offers single-line, bidirectional, ring, radial, spiral, and custom-shaped filling paths to meet various marking needs.High-Precision Motion Compensation

Includes backlash, pitch, and 2D compensation features for stable and accurate control.Flexible API for Development

Provides SDKs and libraries for C++, C#, and other languages, allowing secondary development for customized applications.Stable Offline Operation

Supports offline program execution triggered via I/O or API calls, ensuring system reliability even during network interruptions.

High-Performance Motion Control Core

At the heart of this system is a real-time motion control kernel capable of coordinating up to hundreds of motion axes with a control cycle as low as 125 μs.

It enables ultra-fast communication and ensures synchronization accuracy, even under high-speed rotation and complex marking trajectories.

Conclusion

The open-loop laser galvo motion controller revolutionizes rotary flying marking by enabling seamless synchronization between laser output and motion control.

This technology not only improves marking precision and processing speed but also enhances flexibility for both flat and curved surfaces.

It represents a significant advancement in modern laser manufacturing, offering manufacturers higher efficiency, better consistency, and smarter control integration.