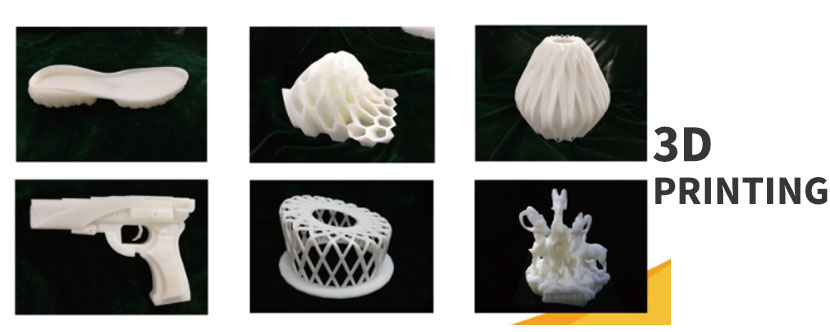

Introduction to 3D Printing Technologies

In recent years, 3D printing has rapidly evolved from a niche prototyping tool into a core manufacturing method across industries. From aerospace and automotive to healthcare and consumer goods, 3D printing enables faster development cycles, customized production, and highly complex designs that traditional manufacturing cannot achieve.

As the technology matured, different 3D printing processes emerged to meet diverse industrial requirements. Among these, SLA, SLS, SLM, and DLP have become some of the most popular and widely adopted methods. Understanding the differences between these technologies is essential for selecting the right process for your application. At the same time, advanced 3D printing software plays a crucial role in supporting each technology, making it easier to design, slice, and manage 3D printer applications from concept to final part.

SLA 3D Printing Technology

SLA (Stereolithography) was one of the first 3D printing technologies ever developed. It uses a laser beam to cure liquid resin layer by layer, building highly detailed parts with smooth surfaces. SLA is particularly valued in industries where fine details, precision, and smooth finishes are critical.

- Process UV laser selectively solidifies resin in a vat

- Materials Photosensitive resin

- Advantages High precision, smooth surface, excellent for prototypes and molds

- Limitations Resin materials can be brittle, limited to certain applications

In modern 3D printing software, SLA settings include laser power, curing time, and support generation, all of which are critical to ensuring successful prints.

SLS 3D Printing Technology

SLS (Selective Laser Sintering) uses a laser to fuse powdered materials layer by layer. Unlike SLA, which works with liquid resin, SLS uses powders like nylon or composite materials. This makes SLS a popular choice for functional parts and low-volume production.

- Process Laser sinters powder particles together

- Materials Nylon, TPU, composite powders

- Advantages Strong, durable parts, no need for support structures

- Limitations Rougher surface finish, powder management can be complex

Advanced 3D printing software for SLS systems supports features like optimized packing density, powder refresh rate calculations, and thermal management for consistent results across large print beds. This is essential in production environments where efficiency is key.

SLM 3D Printing Technology

SLM (Selective Laser Melting) is a metal 3D printing process closely related to SLS, but designed specifically for metal powders. A high-powered laser melts metal powders to form fully dense metal parts, making SLM ideal for aerospace, automotive, and medical implants.

- Process Laser melts metal powder layer by layer

- Materials Stainless steel, titanium, aluminum, cobalt-chrome

- Advantages Fully dense metal parts, complex geometries

- Limitations High equipment cost, post-processing required

3D printing software for SLM must manage laser parameters, scan patterns, and build chamber conditions to prevent defects such as warping or porosity. Advanced simulation tools within the software help predict thermal stresses before printing even begins.

DLP 3D Printing Technology

DLP (Digital Light Processing) is similar to SLA, but instead of using a single-point laser, it uses a digital projector to cure an entire layer at once. This speeds up the printing process while maintaining high resolution. DLP is widely used in dental, jewelry, and product prototyping.

- Process Projected light cures resin layer by layer

- Materials Photopolymer resins

- Advantages Faster than SLA, high resolution, smooth surface

- Limitations Limited build size, resin properties can be restrictive

Modern 3D printing software for DLP systems often includes automated support generation, anti-aliasing algorithms, and optimized exposure settings to ensure both speed and accuracy.

Comparing SLA SLS SLM and DLP

| Technology | Material | Precision | Speed | Cost | Applications |

|---|---|---|---|---|---|

| SLA | Resin | High | Moderate | Medium | Prototyping, dental, jewelry |

| SLS | Nylon, composites | Moderate | Moderate | High | Functional parts, aerospace |

| SLM | Metal powders | High | Low | Very High | Aerospace, automotive, medical implants |

| DLP | Resin | High | High | Medium | Dental, jewelry, product design |

Role of 3D Printing Software in Modern Manufacturing

Regardless of the technology used, 3D printing software plays a vital role in streamlining the entire workflow. From initial design import to slicing, toolpath generation, and machine control, modern software ensures that 3D printer applications run smoothly and efficiently.

- Design Optimization Topology optimization, lightweighting, and part orientation tools

- Slicing and Toolpath Control Precise control over laser paths, exposure times, and layer thickness

- Process Monitoring Real-time feedback on print progress, environmental conditions, and material usage

Leading 3D printing software platforms offer customizable profiles for SLA, SLS, SLM, and DLP, ensuring each machine type performs at its best while simplifying the user experience.

3D Printer Applications Across Industries

The versatility of 3D printing extends far beyond prototyping. Advanced 3D printer applications now cover:

- Aerospace Lightweight parts, complex geometries, on-demand replacement parts

- Automotive Custom tools, jigs, fixtures, functional parts for testing

- Medical Patient-specific implants, surgical guides, dental prosthetics

- Consumer Goods Customized products, jewelry, eyewear, and wearable technology

Each of these 3D printer applications benefits from the unique capabilities of SLA, SLS, SLM, and DLP technologies, combined with the power and flexibility provided by modern 3D printing software.

Conclusion

The choice between SLA, SLS, SLM, and DLP depends heavily on the material requirements, part complexity, and intended application. Each process offers distinct advantages and challenges, making it essential to understand the differences when selecting the right technology for your project. Coupled with advanced 3D printing software, these technologies enable the creation of high-quality parts across a wide range of 3D printer applications, from rapid prototypes to end-use production components.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。