Introduction to 3D Laser Galvo Systems

3D laser galvo systems are cutting-edge technologies used in laser engraving, marking, and micro-machining applications. These systems utilize a galvanometer (or galvo) to rapidly move the laser beam across surfaces, achieving extremely precise control and accuracy. The key advantage of a 3D laser galvo is its ability to offer rapid, high-precision scanning, making it suitable for applications such as laser engraving, cutting, and even 3D printing.

In 3D laser galvo systems, the galvanometer optical scanner plays a vital role by rapidly deflecting the laser beam in both horizontal and vertical directions. This allows for the creation of intricate patterns and designs on complex surfaces with minimal distortion. These systems are widely used in industries like automotive, aerospace, electronics, and medical device manufacturing.

Galvo Mirrors: The Core Component of Galvo Systems

Galvo mirrors are essential components in galvo scanners. These mirrors are mounted on the galvanometer and are responsible for directing the laser beam to the desired position. When a voltage is applied to the galvo mirror, it moves in response, directing the laser to different points on the surface.

The precision of galvo mirrors is critical in laser systems, as any slight deviation in their movement can lead to inaccuracies in the final result. The use of high-quality mirrors allows for highly precise laser scanning, even in dynamic, high-speed applications. Galvo mirrors are often made from materials like polished aluminum or specialized coatings to minimize laser distortion and maximize reflection efficiency.

The Principle of Galvo Mirror Scanning

Galvo mirror scanner head is mainly composed of XY scanning mirror, field mirror, galvo mirror, and computer-controlled marking software. The corresponding optical components are selected according to the different laser wavelengths. Related options also include laser beam expanders, lasers, and more. The working principle is that the laser beam is incident on two mirrors (scanning mirrors), and the reflection point of view of the mirrors is controlled by a computer. The laser focus point of a certain power density moves according to the required requirements on the marking material, and then leaves a permanent mark on the surface of the material, and the focus spot can be circular or rectangular. In the galvanometer scanning mirror system, vector graphics and text can be selected. This method adopts the processing method of graphics software in the computer, which has the characteristics of high drawing efficiency, good graphics accuracy, and no distortion, which greatly improves the laser scanning process. target quality and speed.

Galvo Scanners: Advancing Laser Scanning Technology

A galvo scanner refers to the system that integrates the galvo mirror with the control mechanisms to achieve rapid laser beam deflection. These scanners can quickly change the direction of the laser beam, enabling it to perform complex tasks such as engraving, etching, and marking with high precision.

The combination of galvo scanners and 3D laser systems offers significant advantages for industries that require high-speed operations without compromising on precision. The galvo-based systems are ideal for tasks that require extreme accuracy, such as:

Laser Engraving: High-speed engraving of logos, serial numbers, and custom designs on various materials.

Laser Cutting: Cutting intricate designs in thin materials like metals, plastics, and ceramics.

Marking and Etching: High-quality marking and etching for traceability and identification on metal parts and tools.

Galvanometer Optical Scanners: Precision in Motion

The galvanometer optical scanner is a critical component that enables the scanning of laser beams with remarkable accuracy. It uses the principles of a galvanometer to control the position of the laser in both the X and Y axes. By precisely controlling the laser’s movement, galvanometer optical scanners can create detailed patterns on a wide variety of materials.

These scanners are essential for laser systems that demand precision in both speed and accuracy, such as 3D laser galvo setups used for engraving and micro-machining. The galvanometer optical scanner ensures minimal mechanical movement and high-speed deflection, delivering clean and precise results.

Applications of 3D Laser Galvo Systems and Galvo Scanners

Micro-machining: 3D laser galvo systems are perfect for cutting and engraving on a microscopic scale, enabling the production of small, intricate components for industries such as electronics and medical device manufacturing.

Medical Device Manufacturing: Laser engraving and marking on medical components require precise, accurate, and fast processing, making galvo scanners and 3D laser galvo systems the ideal choice.

Automotive Industry: The automotive industry relies heavily on galvo scanners for marking parts, serial numbers, and barcodes, ensuring quality and traceability in manufacturing.

Aerospace: Precision marking and engraving are critical in aerospace components, and galvanometer optical scanners ensure that every part is precisely marked for safety and traceability.

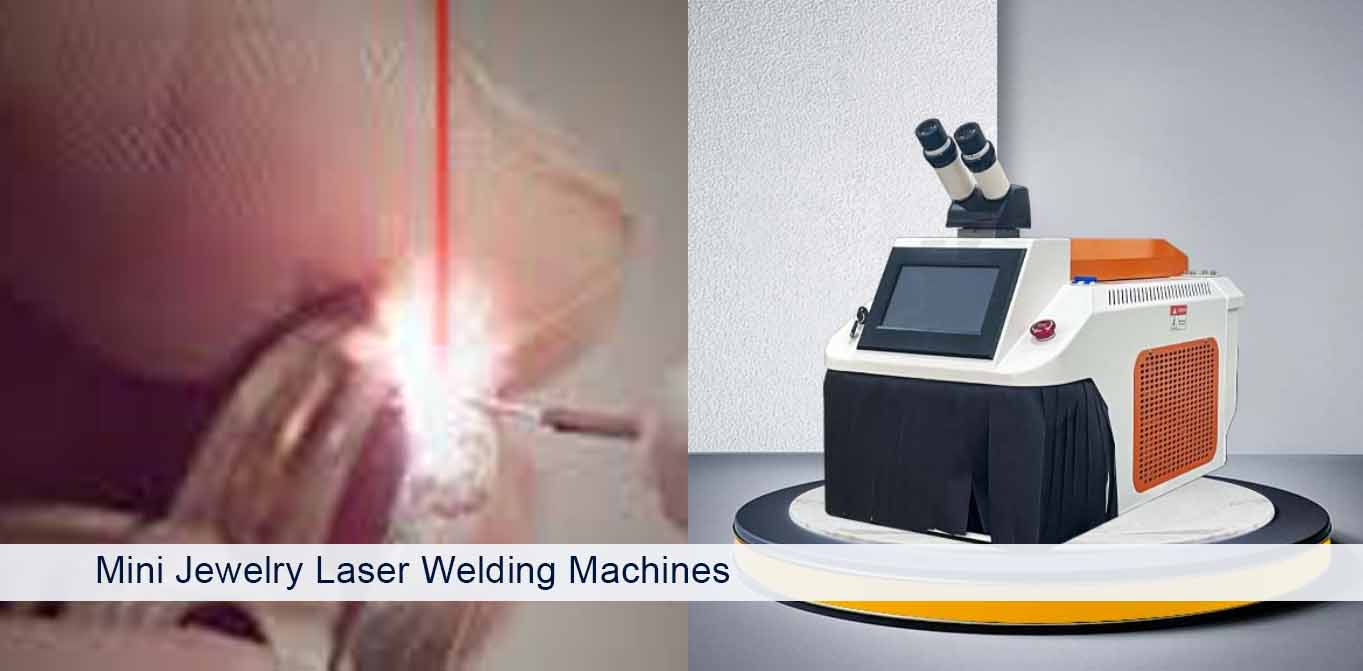

Jewelry and Custom Engraving: Fine engraving on jewelry, watches, and other custom items can be accomplished with high precision using 3D laser galvo systems.

Advantages of Galvo Systems in Laser Applications

High Precision: Galvo-based systems offer incredibly high accuracy, making them perfect for detailed work such as engraving, etching, and micro-machining.

Speed: Galvo scanners can move the laser beam quickly across surfaces, which increases throughput in production environments without sacrificing precision.

Minimal Thermal Impact: The short, controlled bursts of the laser minimize the thermal impact on materials, which is essential for processing sensitive components like electronics and medical devices.

Durability and Reliability: Galvo scanners and galvanometer optical scanners are designed for long-term, continuous operation with minimal wear and tear.

Conclusion: The Future of Laser Technology with Galvo Systems

The advancement of 3D laser galvo technology, galvo mirrors, galvo scanners, and galvanometer optical scanners is shaping the future of laser processing across various industries. These systems enable manufacturers to perform high-precision engraving, cutting, and marking with speed and efficiency, making them indispensable in today’s competitive market.

Whether you are involved in micro-machining, medical device production, or high-quality engraving, galvo systems provide the precision and reliability required for success. As laser technology continues to evolve, these systems will remain at the forefront of innovation in the laser processing industry.