In today’s manufacturing and product identification industry, laser marking has become an essential process for achieving permanent, precise, and high-quality marks. Choosing the right laser marking machine directly impacts product appearance, production efficiency, and long-term traceability.

Among the most widely used technologies are Fiber Laser Marking Machine, CO2 Laser Marking Machine, UV Laser Marking Machine, and Green Laser Marking Machine. Each laser type is designed for specific materials and industries. This guide will help you understand their differences, applications, and how to choose the best solution for your business.

Fiber Laser Marking Machine – Ideal for Metal & High-Speed Production

A Fiber Laser Marking Machine is the most popular choice for industrial metal marking. It uses a 1064nm wavelength fiber laser source, offering excellent beam quality, long service life, and extremely low maintenance costs.

Key Advantages of Fiber Laser Marking Machine:

Perfect for metals such as stainless steel, aluminum, brass, copper, and titanium

High marking speed and outstanding precision

Long laser lifetime (up to 100,000 hours)

Ideal for barcodes, QR codes, serial numbers, logos, and deep engraving

Typical Applications:

Automotive parts

Electronics & PCB components

Tools and hardware

Medical instruments

If you are looking for a reliable, cost-effective solution for metal marking, a Fiber Laser Marking Machine is the best long-term investment.

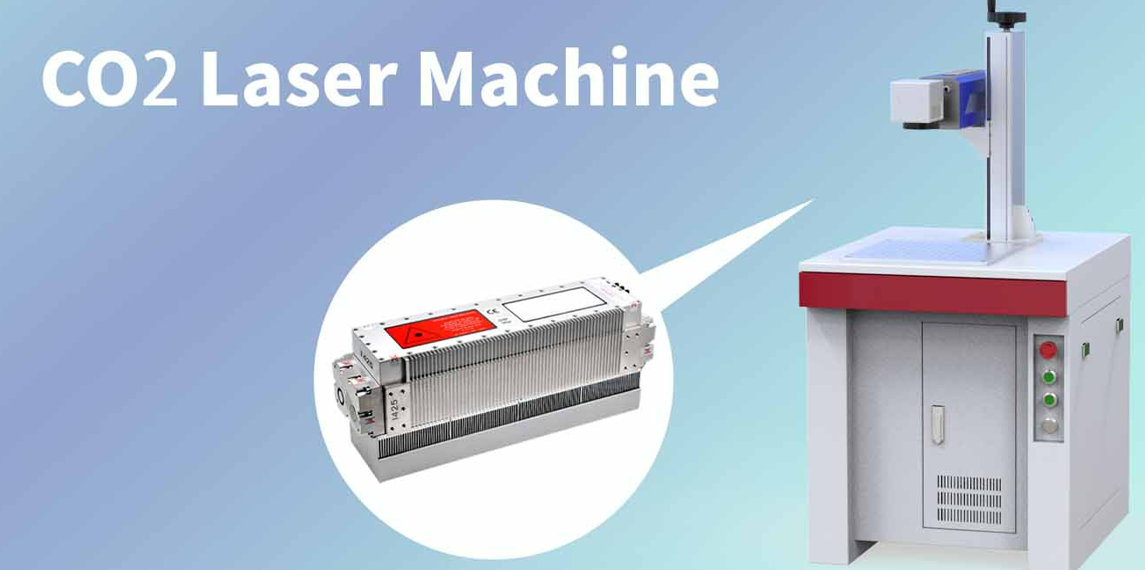

CO2 Laser Marking Machine – Best for Non-Metal Materials

A CO2 Laser Marking Machine operates at a 10.6μm wavelength and is specifically designed for non-metal materials. It provides smooth and clean marking without damaging the surface.

Key Advantages of CO2 Laser Marking Machine:

Excellent performance on non-metal materials

High-speed marking with minimal heat impact

No consumables, low operating cost

Suitable Materials:

Wood

Acrylic

Glass

Leather

Paper and cardboard

Plastics (ABS, PVC, PET)

Common Industries:

Packaging and labeling

Advertising and signage

Craft and gift customization

Food and beverage coding

For businesses focused on non-metal processing, a CO2 Laser Marking Machine delivers efficiency and versatility.

UV Laser Marking Machine – Cold Laser for Ultra-Fine Marking

A UV Laser Marking Machine uses a 355nm wavelength and is known as a “cold laser” marking system. It minimizes thermal damage, making it perfect for delicate and high-precision applications.

Key Advantages of UV Laser Marking Machine:

Extremely fine marking resolution

Minimal heat-affected zone

Ideal for fragile and sensitive materials

Typical Materials:

Plastics (PE, PP, ABS, PC)

Glass

Ceramics

Silicon wafers

Major Applications:

Electronics and semiconductor industry

Medical packaging

Cosmetics and pharmaceutical labeling

If your products require high-contrast, micro-level marking, a UV Laser Marking Machine is the optimal solution.

Green Laser Marking Machine – Perfect for Reflective & Sensitive Materials

A Green Laser Marking Machine operates at a 532nm wavelength and fills the gap between fiber and UV laser technologies. It performs exceptionally well on reflective metals and heat-sensitive materials.

Key Advantages of Green Laser Marking Machine:

Excellent absorption on reflective materials

Higher precision than fiber laser for fine details

Reduced thermal stress

Ideal Materials:

Copper and brass

Gold and silver

Certain plastics and glass

Popular Applications:

Electronics and precision components

Jewelry marking

High-end industrial products

For manufacturers dealing with reflective metals or fine marking requirements, a Green Laser Marking Machine offers unmatched accuracy.

How to Choose the Right Laser Marking Machine?

When selecting a laser marking system, consider the following factors:

Material Type – Metal or non-metal

Marking Precision – Standard or ultra-fine

Production Volume – Low, medium, or high-speed production

Industry Requirements – Electronics, medical, packaging, or industrial manufacturing

Our professional team provides customized laser marking solutions to match your specific production needs.

Why Choose Our Laser Marking Machines?

Stable laser sources and advanced control systems

High-speed galvo scanning technology

Custom configurations for global customers

Professional technical support and fast response

Competitive pricing for overseas distributors and manufacturers

Whether you need a Fiber Laser Marking Machine, CO2 Laser Marking Machine, UV Laser Marking Machine, or Green Laser Marking Machine, we help you achieve superior marking quality and higher production efficiency.

Get More Inquiries Today

Looking for a reliable laser marking solution to improve your product identification and brand value?

Contact us now to receive technical consultation, machine specifications, and a competitive quotation tailored to your application.