High-power picosecond lasers, with their extremely high peak power and narrow pulse width (10⁻¹² s), have been widely applied in precision material processing, LED chip dicing, solar photovoltaic manufacturing, and scientific research. Compared with traditional nanosecond lasers (10⁻⁹ s), picosecond lasers offer higher machining precision, minimal thermal effects, and burr-free edges. In contrast to femtosecond lasers (10⁻¹⁵ s), picosecond lasers also have unique advantages: they do not require pulse stretching and compression during amplification, resulting in a simpler system design, lower cost, and higher reliability. At the same time, their ultrashort pulse duration remains sufficient to achieve stress-free, highly precise micromachining.

Currently, there is a strong demand for industrial-grade picosecond lasers. However, most of the high-end systems are still imported, which makes them expensive and challenging to maintain. Domestic production has gradually advanced, but large-scale adoption is still limited due to stability and performance concerns.

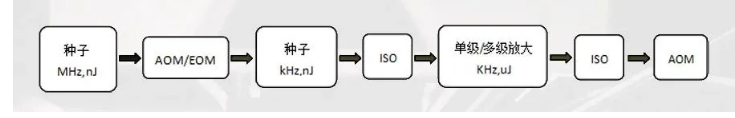

For industrial applications, the single-pulse energy of a picosecond laser usually needs to reach the microjoule or even sub-millijoule level. Since mode-locked seed lasers typically operate at MHz frequencies with pulse energies in the nJ range, pulse-picking technology is required to reduce the repetition rate, followed by high-gain amplification to achieve the desired single-pulse energy. As shown in the typical working principle of a picosecond laser system, the main components include a seed laser, a pulse-picking unit, and an amplifier. High-frequency seed pulses are selectively picked down to kHz levels using acousto-optic or electro-optic modulators, then amplified through one or multiple amplification stages to deliver high single-pulse energy. The critical enabling technologies can be summarized as follows:

1. Picosecond Seed Source Technology

The seed laser is the core of a picosecond laser system, directly determining stability and reliability. The seed source is also the most fragile part of the system, and the key challenge lies in extending the lifetime of the saturable absorber mirror (SESAM) used for mode-locking.

There are generally two types of seed sources: solid-state seed lasers based on semiconductor pumping, and fiber-based seed lasers. Solid-state seeds often suffer from drawbacks such as complex structure, larger size, high cost, and lower long-term stability. Their SESAM typically operates under higher thermal and optical loads, leading to lifetimes shorter than 1500 hours. To meet industrial demands of over 10,000 hours, frequent adjustments or replacements are required.

In contrast, fiber-based seed lasers exhibit much lower thermal load on the SESAM, extending lifetimes well beyond 10,000 hours without significant maintenance. Additionally, fiber seed sources feature simpler structure, lower cost, higher stability, and near maintenance-free operation, making them the preferred choice for modern picosecond laser systems.

2. Picosecond Amplifier Technology

To achieve high single-pulse energy, seed pulses must be amplified through high-gain amplifiers. The main challenges in amplifier design are maintaining beam quality while preventing optical damage under high peak powers. Three types of high-gain amplifiers are commonly used:

Fiber Amplifiers

Advantages: high output power, high gain (>10⁹), simple and stable structure, and relatively low cost.

Limitations: nonlinear effects in fibers restrict the maximum achievable single-pulse energy, usually limited to below 10 μJ.Regenerative Amplifiers

Advantages: high gain and ability to achieve >200 μJ single-pulse energy.

Limitations: complex cavity structure, strict timing requirements, need for Pockels cell-based cavity dumping, high cost, and relatively lower operational stability.Multi-Pass Amplifiers

Advantages: simpler design, reliable operation, lower cost, and easy scalability for higher pulse energies.

Limitations: single-stage gain is modest (10³–10⁴), but higher total gain can be achieved by cascading multiple stages.

3. Pulse Picking Technology

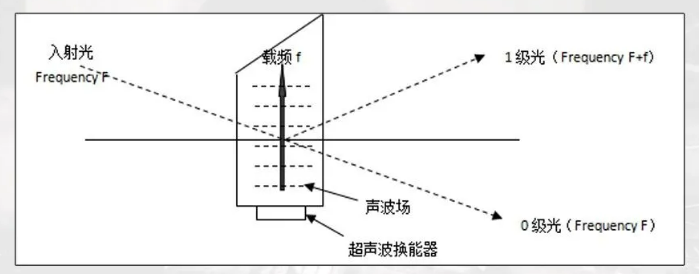

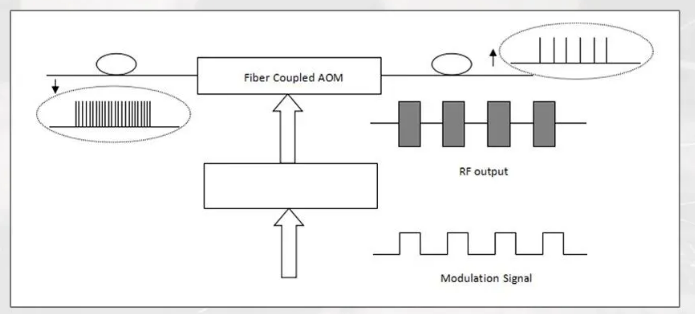

Another key element of picosecond laser design is pulse picking, which reduces the repetition rate of the high-frequency seed source. This is typically achieved using acousto-optic modulators (AOMs) or electro-optic modulators (EOMs). Both rely on nonlinear crystal effects to selectively transmit certain seed pulses while blocking others, effectively lowering the pulse repetition frequency to the desired kHz range.

For example, in an AOM, an acoustic wave propagating through the crystal induces a periodic refractive index change, which can diffract and modulate the seed beam. By synchronizing the modulation with the seed pulses, only selected pulses pass through to the amplifier, ensuring proper energy scaling.

4. Advanced Control Technologies

In addition to seed source, amplifier, and pulse-picking technologies, modern picosecond lasers also rely on advanced system control methods:

Pump Source Driving and Thermal Management: Ensures stable pump power and wavelength, directly affecting laser output stability.

Pulse Synchronization: Critical for regenerative amplification and precise timing in industrial machining applications.

Data Recording and Monitoring: Enables real-time tracking of operational parameters, facilitating predictive maintenance and system optimization.

Power Regulation and Feedback Control: Allows continuous adjustment of output power, essential for process stability in industrial micromachining.

Conclusion

High-power picosecond lasers represent a balance between complexity, cost, and performance. They combine the precision of ultrafast processing with higher robustness and simpler structure compared to femtosecond systems. Continued development of reliable seed sources, efficient amplification architectures, advanced pulse-picking strategies, and intelligent control systems will be the key to enabling broader adoption in fields such as precision micromachining, semiconductor manufacturing, and scientific research.