Introduction

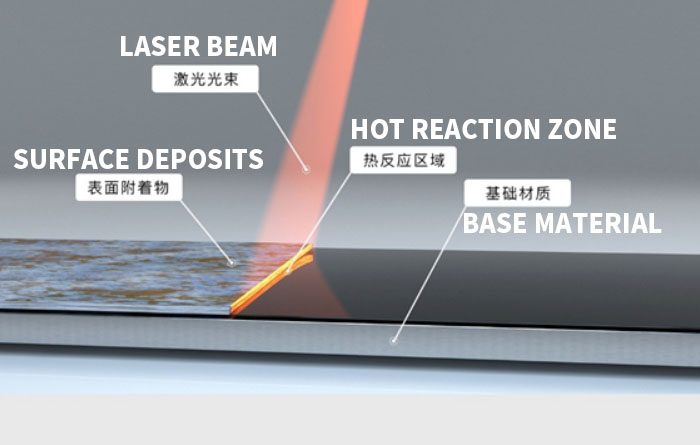

Laser cleaning is an advanced surface treatment technology that uses a high-energy laser beam to instantly evaporate and remove surface contaminants such as rust, paint, oil, or coatings. Compared with traditional mechanical, chemical, or ultrasonic cleaning methods, laser cleaning stands out for its precision, efficiency, and controllability. It offers a non-contact, environmentally friendly, and damage-free cleaning process that greatly improves surface quality and extends component lifespan. As modern industries demand higher-quality surface finishes, laser cleaning technology has become a key solution for achieving both performance and sustainability.

Applications of Laser Cleaning in Modern Industry

With the rise of smart manufacturing and green production, laser cleaning is becoming one of the most promising industrial cleaning methods. Its precise, efficient, and eco-friendly characteristics make it a powerful alternative to conventional cleaning techniques in high-end equipment manufacturing, precision electronics, aerospace, and other sectors. The continuous emergence of new materials and processes further expands its potential applications.

1. Metal Surface Cleaning

In metal processing, laser cleaning machines are widely used for removing oil films, paints, coatings, and oxide layers from materials such as stainless steel, aluminum alloy, and carbon steel. The process ensures no damage to the base metal while providing excellent adhesion for subsequent coatings or welds. In the aerospace and automotive industries, laser cleaning can selectively remove old paint or coatings from aircraft skins or auto parts, preparing them for repainting or welding with enhanced quality and durability.

Laser cleaning coating

Laser cleaning of oil film on metal surface

2. Non-Metallic Material Cleaning

Laser cleaning is equally effective for non-metallic materials such as glass, ceramics, stone, and composite materials. For example, laser systems can clean insulators in power equipment without contact or remove graffiti and biological growth from stone surfaces. In the case of carbon fiber reinforced polymers (CFRP), laser cleaning precisely removes epoxy resin layers, improving bonding strength while preventing fiber damage that may occur with mechanical grinding. This makes laser cleaning a reliable tool for composite material maintenance and manufacturing.

3. Semiconductor and Microelectronics Applications

In semiconductor manufacturing, where even microscopic contamination can cause defects, laser cleaning enables the removal of nano-level particles such as copper or alumina from silicon wafers. It ensures ultra-clean surfaces essential for integrated circuit fabrication. Moreover, laser cleaning is applied to photomask maintenance through plasma shockwave mechanisms that avoid substrate damage—making it suitable for extreme ultraviolet (EUV) lithography and other advanced semiconductor processes.

Future Prospects

The future of laser cleaning technology lies in its integration with high-end manufacturing, environmental protection, and intelligent automation.

In high-end manufacturing, laser cleaning will be deeply applied to aerospace component maintenance, electric vehicle battery pre-welding treatment, and semiconductor wafer cleaning—boosting both precision and productivity.

From an environmental standpoint, its pollution-free nature will help replace traditional chemical cleaning in industries with strict ecological standards such as nuclear decontamination and petrochemical maintenance.

In the era of smart industry, the combination of laser cleaning systems with AI-based visual recognition and industrial robotics will enable automatic parameter adjustment and adaptive operation under complex conditions—ushering in a new generation of intelligent cleaning solutions.

Conclusion

As industries move toward cleaner, smarter, and more precise production, laser cleaning technology will continue to redefine how we treat and maintain material surfaces. With its precision, eco-friendliness, and broad adaptability, laser cleaning is not just a replacement for old methods—it represents the next evolution in surface treatment, leading global manufacturing into a new era of efficiency and sustainability.