A high-performance laser engraving machine depends not only on the laser source itself, but also on the quality and precision of its core components. Among the most critical laser engraving machine parts, the laser optical system, rotary axis, and Z axis lift play a decisive role in engraving accuracy, stability, and production efficiency.

This article introduces the functions, advantages, and applications of these essential components, helping buyers and integrators choose the right configuration for their laser engraving systems.

Laser Optical System – The Core of Precision and Beam Quality

The laser optical system is responsible for transmitting, shaping, and focusing the laser beam onto the workpiece. A high-quality laser optical system ensures minimal energy loss, excellent beam quality, and consistent engraving results.

Key Components of a Laser Optical System:

Collimating lenses

Beam expanders

Reflective mirrors

F-theta scanning lenses

Protective windows

Advantages of a High-Quality Laser Optical System:

Improved engraving accuracy

Stable spot size and focal depth

Reduced thermal distortion

Longer service life of optical components

In industrial laser engraving machines, a reliable laser optical system is essential for metal marking, plastic engraving, ceramic processing, and high-speed production lines.

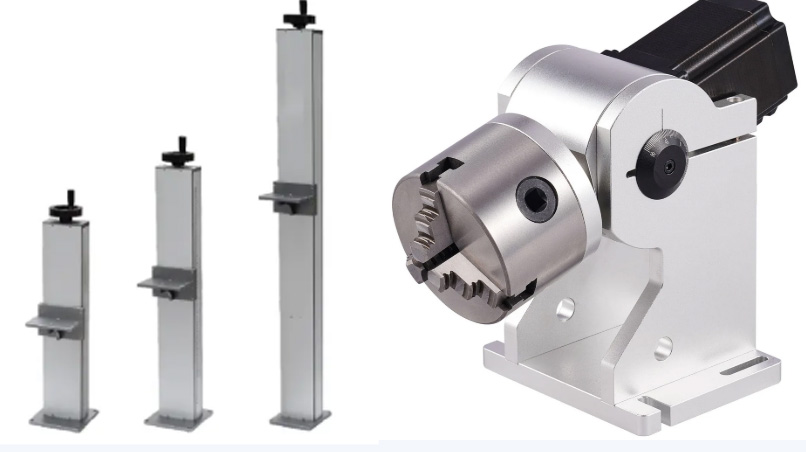

Rotary Axis – Expanding Laser Engraving Capabilities

A rotary axis is a crucial accessory that enables laser engraving on cylindrical and curved objects. By synchronizing rotation with laser scanning, the rotary axis allows uniform engraving on round surfaces.

Typical Applications of a Rotary Axis:

Engraving rings, bracelets, and jewelry

Marking bottles, tubes, and pipes

Cylindrical metal and plastic parts

Customized promotional products

Benefits of Using a Rotary Axis:

Accurate 360-degree engraving

Stable rotation speed and positioning

Easy integration with laser engraving software

Expanded processing flexibility

Adding a rotary axis significantly increases the application range of laser engraving machines, making it an essential upgrade for customized and batch production.

Z Axis Lift – Precise Focus Control for Different Workpieces

The Z axis lift controls the vertical movement of the laser head or worktable, allowing precise focus adjustment for materials of different thicknesses. Accurate Z-axis positioning is critical for maintaining optimal focal distance during engraving.

Features of a Z Axis Lift:

Motorized or manual lifting options

High positioning accuracy

Smooth and stable movement

Strong load-bearing capacity

Why Z Axis Lift Matters:

Ensures consistent engraving depth

Improves processing quality on uneven surfaces

Reduces setup time and manual adjustment

Supports automation and batch production

A well-designed Z axis lift enhances both engraving precision and operational efficiency in modern laser engraving systems.

Laser Engraving Machine Parts – Complete and Reliable Solutions

In addition to the laser optical system, rotary axis, and Z axis lift, high-quality laser engraving machine parts include:

Galvo scanners and scan heads

Control boards and drivers

Motion controllers

Cooling systems

Protective enclosures and safety components

Using reliable and well-matched laser engraving machine parts ensures long-term machine stability, reduced maintenance cost, and consistent production performance.

How to Choose the Right Laser Engraving Machine Parts?

When selecting laser engraving machine parts, consider the following factors:

Material type and processing requirements

Engraving precision and speed

Compatibility with existing laser systems

Production environment and workload

Long-term reliability and service support

Choosing the right laser optical system, rotary axis, and Z axis lift helps optimize engraving quality while maximizing return on investment.

Why Choose Our Laser Engraving Machine Parts?

We provide professional laser optical systems, rotary axis units, Z axis lift mechanisms, and complete laser engraving machine parts for global customers. Our advantages include:

Industrial-grade precision and stability

Flexible customization options

Compatibility with mainstream laser controllers

Fast delivery and technical support

Whether you are building a new laser engraving machine or upgrading an existing system, our components are designed to meet industrial standards and demanding production needs.

Contact us today for technical consultation and a fast quotation.