For integrators, project managers, and technical personnel, integrating laser equipment into production lines is a complex yet essential task. Achieving high-quality marking ensures traceability of parts, but requires a series of steps to guarantee safe and compliant installation. Here’s a practical guide for integrating laser marking machines into production lines.

Step 1: Preparation

Before starting, a feasibility study is necessary. In addition to verifying technical compatibility, power requirements, and laser specifications, a thorough environmental analysis is essential. Temperature stability, dust, oil contamination, and available space must all be assessed.

1. Technical Verification

Determine technical specifications, including power, marking quality, and marking speed.

Verify requirements such as positional limits and select the appropriate laser type.

Conduct sample tests to demonstrate that the solution meets the client’s specifications and ensure compatibility with existing equipment.

2. Environmental Analysis

The laser controller is the core of the control system and contains highly sensitive components. Like a PLC, the external environment must be carefully considered. Temperature, humidity (excessive humidity can damage electronics and reduce marking precision), dust, and mechanical vibration are all key parameters. Depending on these factors, dust filters, air conditioning enclosures, or vibration-damping pads may be required to protect the central unit.

To ensure consistent performance and durability, marking conditions should remain as stable as possible over time. For example, the 1400th mark should be as consistent as the first one. Recommended operating temperature ranges for fiber, hybrid, and green-light laser marking machines are 10–40°C.

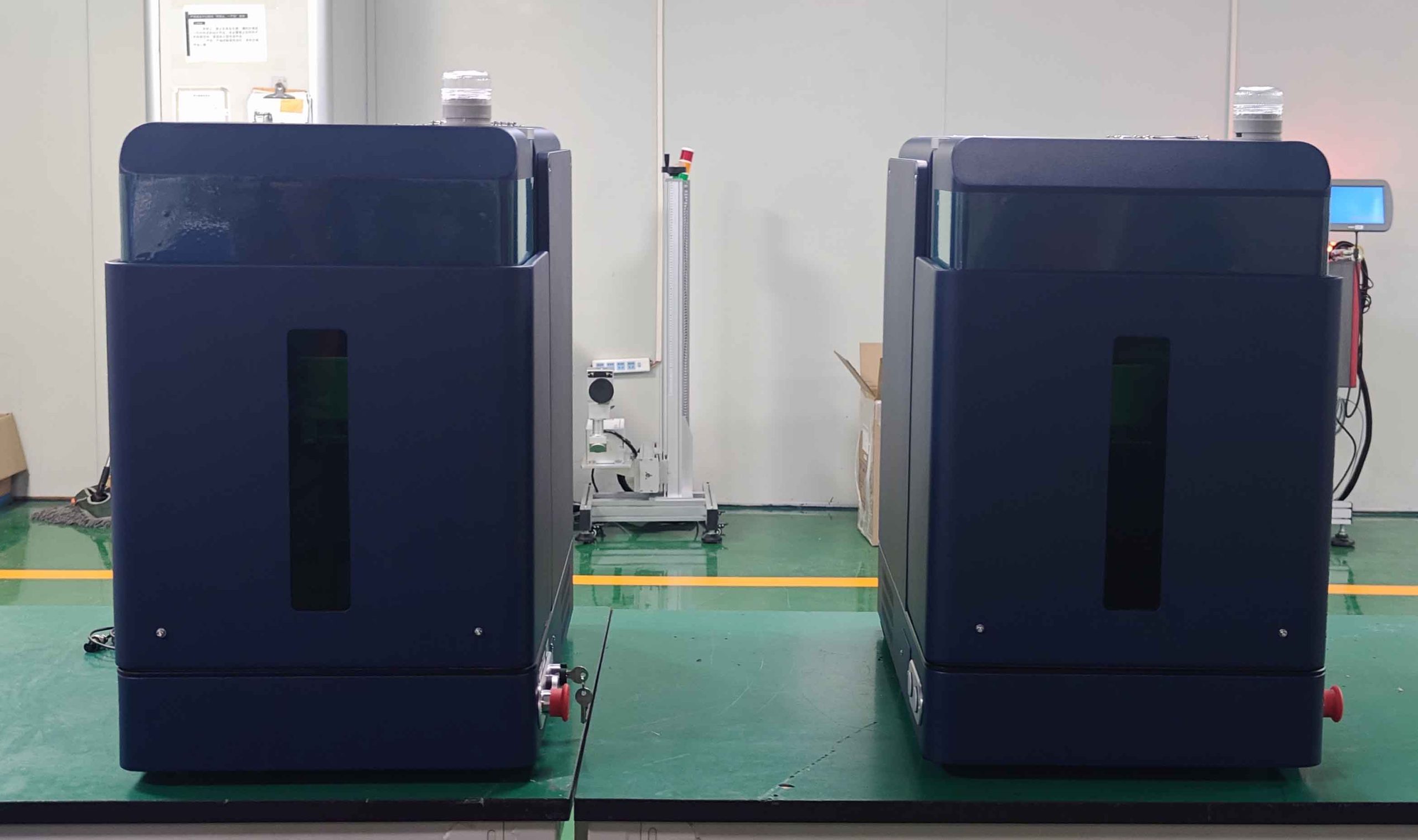

3. Laser Machine Size and Space Requirements

When preparing for installation, consider the size of the laser machine and its accessories to avoid mechanical interference with the production line. Using 3D visualization can facilitate preparation and ensure space constraints are met.

Important: Provide adequate conduits and openings for fiber optics and cables. Fibers have a minimum bending radius and must be protected from external damage.

Step 2: Environmental Considerations

1. Smoke Extraction

A smoke extractor is crucial for equipment performance, operator safety, and regulatory compliance.

Position the exhaust near the marking area to ensure efficient extraction.

Better enclosure sealing improves extraction efficiency.

Risks of inadequate smoke extraction:

Accumulation of smoke, particles, and dust.

Contamination and aging of the marking machine, especially the lens.

Gradual decline in marking quality.

Increased fire risk.

Harm to operators’ health.

2. Electrical Stability

Monitor electrical compliance and power stability. Voltage fluctuations may cause equipment failure, and poor grounding can damage the mainboard or galvanometer. Ensure the power supply is stable and within specifications (compatible with 100–240V input).

Step 3: Mechanical Considerations

1. Vibration Threshold

When parts are moved by actuators, vibrations must not damage the laser marking machine or the workpiece. Assess the maximum tolerable vibration and consider installing damping or isolation devices to maintain marking quality and precision.

2. Focus

Adjust the focal distance to achieve the desired marking effect. Short focal lengths are suitable for fine marking, while longer focal lengths are better for larger or curved surfaces.

3. Cable Bending Radius

Monitor the bending radius of cables to maintain integrity and prevent premature wear.

Step 4: Operator Safety

Regardless of operator position, the laser beam must be fully contained to prevent direct exposure. This includes effective protection against the laser beam, smoke, and particles during marking.

Use a safety viewing window for convenience while maintaining high protection levels.

Enclosures block harmful laser radiation, ensuring safety. They typically include metal, laser-safe glass, and treated plastics to absorb laser radiation.

Enclosures should meet international laser safety standards such as ISO 11553-1, EN 207, or EN 60825-1.

Safety systems may include sensors and alarms.

Smoke extraction is also integrated into the enclosure, effectively removing dust and particles generated during marking.

This guide provides a structured approach to safely integrate laser marking machines into production lines while maintaining performance, quality, and operator safety.