After spending enough time on the production floor, you’ll notice one thing:

Even if two machines are both called “laser marking machines,” the efficiency gap between them can be huge. Over the past year, one question has become increasingly common:

What exactly is the difference between a visual positioning laser marking machine and a standard laser marker?

Is it worth spending the extra money?

This article explains the real difference from a manufacturing perspective, so you can choose the machine that truly fits your production line.

1. The Essential Difference: Whether the Machine Has “Eyes”

A standard laser marking machine relies on fixtures for positioning.

This means the workpiece must be placed perfectly; even a few millimeters of deviation will shift the marking. Operators must constantly align, clamp, and fine-tune.

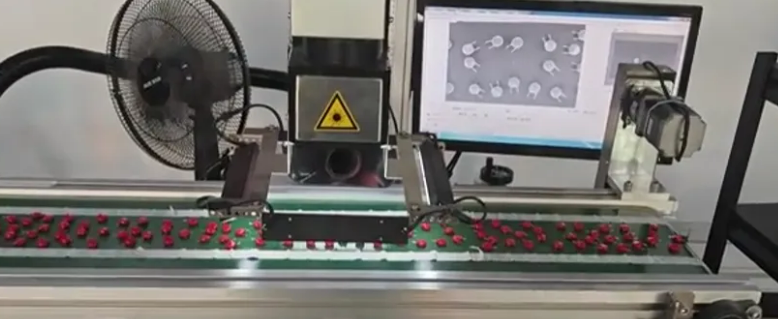

A visual positioning laser marking machine, on the other hand, includes an industrial camera and recognition algorithms. In simple terms, the machine now has “eyes” that can automatically detect shape, contour, holes, QR codes, and other key features.

This leads to major differences:

Slightly misaligned parts are no longer a problem

Irregular shapes can be recognized

Parts can be placed faster with stable cycle time

Operators require far less skill

If your products are small, high-volume, irregular, or require frequent changeovers, visual positioning becomes extremely valuable.

2. Productivity Improvement: Not Just a Little Bit

Standard Laser Marker: Human-Based Positioning

A skilled operator can handle roughly 400–600 pcs per hour, depending on shape complexity.

Changeovers and fixture adjustments take time and reduce efficiency.

Visual Positioning Laser Marker: Automatic Alignment

Once the vision template is calibrated, parts can be placed freely. The machine recognizes and aligns automatically, almost completely eliminating human influence.

Real production data from electronics and automotive plants show:

30%–80% efficiency boost with the same manpower

Changeover time reduced from several minutes to a few seconds

More consistent quality during night shifts or with temporary workers

This is why many factory owners never want to go back once they’ve tried visual machines.

3. Completely Different Application Scenarios

Standard Laser Marker Works Best for:

Single product type

Regular shapes

Fixture-based positioning

Stable operators

Cost-sensitive workshops

Examples: metal parts, large-volume products with fixed shapes, flat plates.

Visual Positioning Laser Marker Works Best for:

Multi-type, small-batch production

Irregular shapes

Small components (easy to misplace)

Automated line integration

High consistency requirements (±0.05–0.1 mm)

Examples: electronic components, automotive interior parts, injection-molded parts, chip housings, medical devices.

4. Marking Accuracy: A “Ceiling-Level” Difference

Even with excellent fixtures, standard machines suffer from:

Different placement angles by operators

Fixture wear

Product size variation between batches

Thermal expansion and mechanical drift

Typical marking accuracy: ±0.2 mm (depends on fixture and operator).

Visual positioning laser marking machines achieve:

±0.05 mm to ±0.1 mm, consistently and quantifiably.

For industries marking brand logos, QR codes, serial numbers, or fine graphics, this level of precision directly affects perceived product quality.

5. Scrap Rate and Defect Rate: Major Difference

Standard machines rely heavily on humans.

After 1–2 hours of continuous operation, operator errors increase significantly.

With new workers, mistakes such as misalignment, shallow marking, and missed marking happen more often.

Visual positioning machines significantly reduce such issues:

Auto angle correction

Auto position recognition

Auto offset adjustment

Auto detection of missing or wrong parts

Real factory data shows:

Defect rate dropped from 1%–3% to below 0.1%.

For high-value parts or industries with penalty risks (automotive, medical), this cost saving is far greater than the machine’s price.

6. Learning Curve: Skilled-Labor-Dependent vs. Process-Driven

Standard machine requires experience:

Positioning by “feel”

Manual focus adjustments

Repeated fixture debugging

Long training time for changeovers

Visual positioning machine is more “system-driven”:

Capture image to build template

Set recognition area

Choose marking content

Save template

This reduces dependency on skilled workers—ideal for factories facing labor shortages or high turnover.

7. Price Difference—Is It a Scam? Absolutely Not

Many owners ask:

“Why is visual positioning so much more expensive? Is it just hype?”

Let’s break down the added cost:

Industrial camera (high frame rate, high resolution)

Lens + lighting systems (customized for materials)

Vision algorithm software

Advanced control boards

Upgraded mechanical and control modules

A visual positioning system usually costs $1,000–$4,000 more (varies by industry and configuration).

But it quickly saves far more:

One skilled operator’s labor cost

Scrap due to marking mistakes

More stable production and shorter lead times

Smooth integration into automation lines

For high-value, small-size, high-precision components, switching earlier saves more money.

8. When Must You Choose Visual Positioning? A Practical Formula

A simple, powerful rule for factory decisions:

If the operator’s placement error > half of your allowable marking tolerance → you MUST choose visual positioning.

Example:

Placement error: ±0.6 mm

Allowable marking deviation: ≤ ±0.3 mm

A standard machine will NEVER meet this requirement. Visual positioning becomes mandatory.

9. Final Conclusion: Visual Positioning Isn’t a Gimmick—It’s the Future

In one sentence, the core difference:

Standard laser markers rely on “fixtures + humans.”

Visual positioning machines rely on “cameras + algorithms.”

Or more directly:

Standard machines depend on operator skill.

Visual machines depend on system intelligence.

As manufacturing moves toward automation and flexible production, visual positioning laser marking machines will become the mainstream—especially for irregular shapes, small components, and high-precision industries.

If your production is facing:

Slow changeovers

Labor shortages

Unstable marking accuracy

Inconsistent cycle time

Plans to integrate automation

Then a visual positioning laser marking machine will solve far more problems than you expect.

Interested in Improving Your Marking Efficiency?

If you want help choosing the right configuration or comparing different laser marking solutions, feel free to contact us:

Contact us for technical consultation, product recommendations, or sample testing.

We’re here to help you upgrade your production with smarter, more efficient laser marking technology.