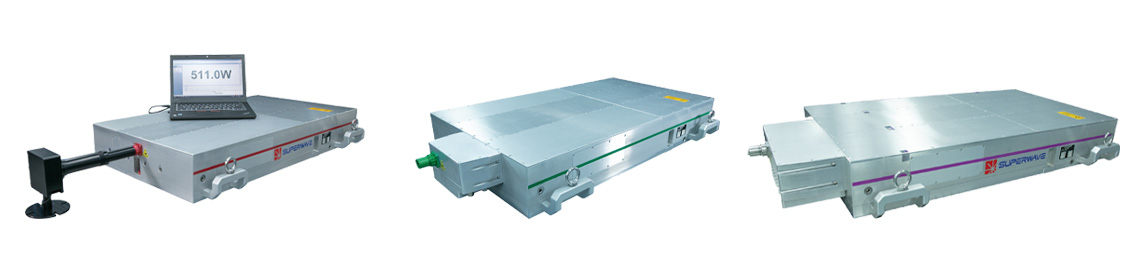

Introduction to Picosecond Laser Technology

The picosecond laser represents a major leap in precision laser technology. Unlike traditional lasers that emit pulses in nanoseconds or milliseconds, the picosecond laser emits ultrashort pulses—each lasting only a trillionth of a second (one picosecond). This extraordinary speed allows the laser to deliver energy so quickly that heat does not have time to spread to surrounding tissue or material, resulting in cleaner, faster, and more precise results.

Among the different types, the picosecond fiber laser stands out for its efficiency, stability, and compatibility with a wide range of applications.

Key Applications of Picosecond Laser

1. Precision Micromachining

The picosecond fiber laser is ideal for micro-scale material processing. Industries such as electronics, medical devices, and semiconductors use picosecond lasers for:

Micro-drilling of ceramics and silicon wafers

Fine cutting of thin metals and polymers

Engraving on hard and brittle materials like glass or sapphire

Thanks to its ultra-short pulses, the picosecond laser can ablate material with minimal thermal damage, known as “cold ablation”, which is critical for high-value precision components.

2. Medical and Aesthetic Treatments

In dermatology and cosmetic medicine, picosecond laser systems are widely used for:

Tattoo removal (all colors, faster sessions, minimal scarring)

Pigmentation treatment (melasma, sun spots, acne marks)

Skin rejuvenation and wrinkle reduction

Compared to traditional Q-switched lasers, picosecond lasers offer better efficacy and faster recovery times due to their shorter pulse durations and photoacoustic effects.

3. High-Speed Marking and Engraving

Picosecond fiber lasers are perfect for high-speed, high-contrast marking on metals and plastics. They’re commonly used for:

QR code marking

Serial number engraving

Anti-counterfeiting microtext

Because of the minimal heat-affected zone, the marking is clean, durable, and does not damage delicate surfaces.

Advantages of Picosecond Fiber Laser

| Feature | Benefit |

|---|---|

| Ultrafast pulses | High precision, minimal thermal damage |

| High peak power | Effective for hard materials and deep marking |

| Stable beam quality | Uniform results over time |

| Compact and efficient | Ideal for industrial integration |

| Low maintenance | Long-lasting with fiber-based design |

Picosecond fiber laser systems are especially valued in modern manufacturing for their speed, accuracy, and low operational cost compared to older laser technologies.

How Picosecond Laser Compares to Nanosecond Lasers

While nanosecond lasers are still widely used, picosecond lasers outperform them in many advanced applications. The shorter pulse duration leads to:

Less heat diffusion

Fewer side effects (in medical treatments)

Finer details in micromachining

Higher ablation efficiency

If your process requires minimal damage, ultrafast repetition, and extreme precision, picosecond fiber lasers are the best choice.

Conclusion: Why Choose a Picosecond Laser?

The picosecond laser is revolutionizing industries where precision, speed, and minimal thermal effects are essential. From industrial micromachining to medical aesthetics, this technology opens the door to new possibilities that traditional lasers cannot match. Investing in a picosecond fiber laser means embracing the future of ultrafast laser processing.