From Root Causes to Control Strategies and the Advantages of Femtosecond “Zero-Taper” Processing

Introduction

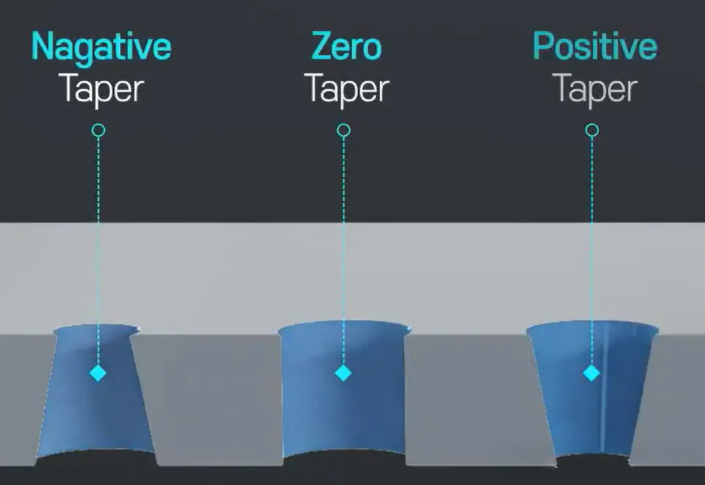

In real production, laser drilling or cutting rarely produces perfectly straight-wall holes or kerfs with identical entrance and exit diameters. What we normally see is “larger at the top, smaller at the bottom” or the opposite—various forms of taper. Many people attribute this to machine precision or improper parameter tuning, but the essence lies in beam propagation, limited depth of focus, material-removal mechanisms, and melt-ejection behavior.

This article explains:

Why laser processing naturally generates taper

Mature beam-engineering solutions for reducing or approaching “zero taper”

Which micro-hole products truly require near-zero-taper machining

The advantages of femtosecond lasers in zero-taper processing and where they can replace traditional technologies

1. Why Does Laser Processing Produce Taper?

The taper of laser-drilled holes or laser-cut kerfs is a geometric result determined by a combination of energy distribution, beam propagation, material response, and melt evacuation.

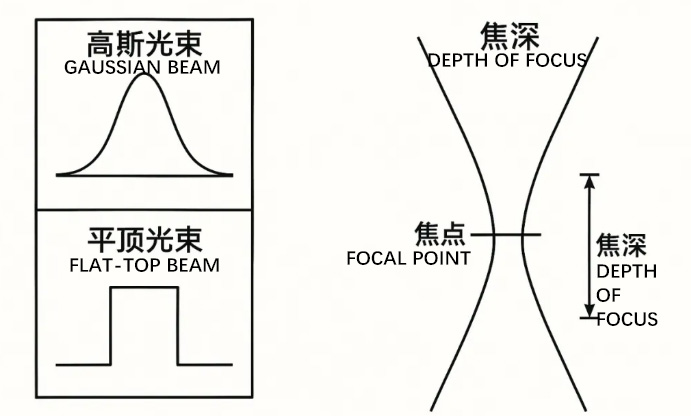

1.1 Beam Distribution & Depth of Focus: A Structural Issue of Gaussian Beams

Most industrial lasers approximate a Gaussian beam:

Highest energy density in the center, gradually decreasing toward the edges

After focusing, the focal intensity is high but the effective depth of focus (DOF) is limited

Typical results in drilling/cutting:

The entrance surface experiences prolonged exposure to high energy, easily causing “over-burning” and enlargement

As the hole becomes deeper, the focal plane shifts upward relative to the hole bottom

The spot becomes larger at the bottom, energy density decreases, and ablation efficiency drops

This naturally favors positive taper holes (top larger, bottom smaller), even if machine precision is excellent.

1.2 Multiple Reflections Inside the Hole: Effective Energy Decays Rapidly

When the hole depth approaches several times its diameter, the interior behaves like a narrow waveguide:

Light undergoes multiple reflections and scattering on the hole wall

The effective numerical aperture decreases

High-reflective materials (Cu, Al) cause even larger energy loss

As a result:

The deeper the hole, the less energy reaches the bottom

The bottom cannot maintain stable ablation, increasing taper

1.3 Material-Removal Mechanism: Molten Pool Dynamics Shape the Hole Profile

For nanosecond and many picosecond lasers, material removal involves melting + vaporization + melt ejection:

A molten pool forms at the hole bottom

Vapor pressure ejects molten material upward

The entrance region repeatedly melts and resolidifies, reshaping the top boundary

Re-solidified spatter on walls locally narrows the lower section, worsening taper

Even when using femtosecond or high-quality picosecond lasers, deep holes still exhibit:

Entrance region remains more active

Bottom region receives less energy

Thus taper is reduced but not fully eliminated.

1.4 Assist-Gas Dynamics and Melt Ejection

Assist gas is usually introduced from the top:

The upper part of the hole is cleaned more effectively

Deeper sections face higher flow resistance and poorer melt evacuation

Macroscopic result:

Upper diameter remains stable

Lower section narrows due to deposited spatter

Taper is further increased

2. How to Reduce Taper in Engineering Practice?

From a process-engineering perspective, reducing taper requires:

Making the energy distribution more uniform along the depth and precisely controlling the material-removal contour.

Key beam-engineering approaches focus on making the beam “longer and straighter.”

2.1 Top-Hat / Flat-Top Beams

Using diffractive optical elements (DOEs) or micro-structured beam shapers:

Energy distribution becomes more uniform

The hole entrance is less likely to be enlarged by an intense center peak

Particularly effective for thin sheets, shallow holes, and film cutting

Limitation: DOF is still restricted—deep holes require additional methods (e.g., dynamic focusing).

2.2 Bessel Beams / Non-Diffraction Beams

Advantages of Bessel beams:

Extremely long depth of focus

Central lobe intensity remains stable over hundreds of microns or more

This ensures:

The full hole depth receives near-uniform energy

Much better perpendicularity and reduced taper

Side-lobe control is necessary to avoid ring-shaped roughness on the hole wall.

2.3 Composite Beams (Gaussian + Annular / Quasi-Bessel)

Composite beams balance efficiency and quality:

Central Gaussian peak ensures high removal rate

Surrounding ring or Bessel-like energy compensates edge and depth regions

These beams provide a practical balance between taper, wall quality, and throughput—suitable for mass production.

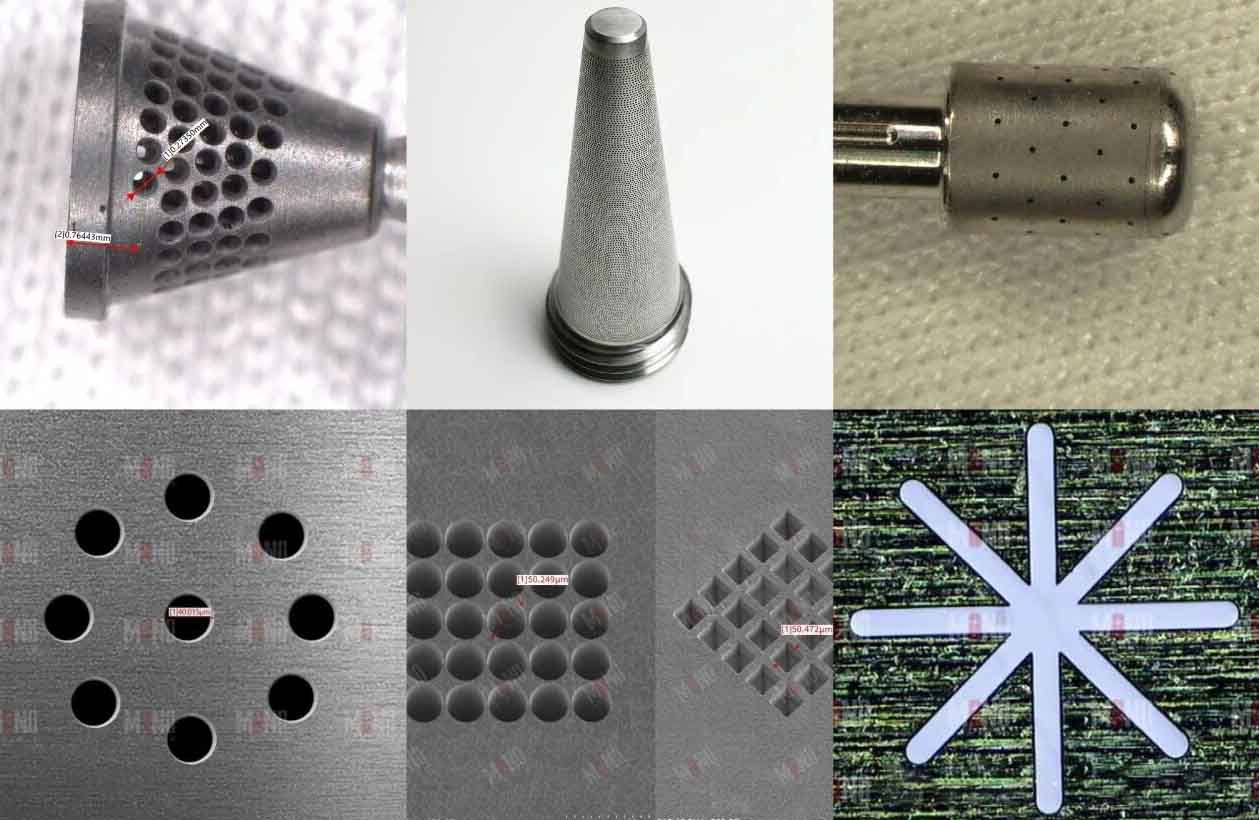

3. Which Micro-Hole Products Require Zero-Taper or Near-Zero-Taper?

Not all micro-holes require strict taper control, but many high-value products are extremely sensitive to hole geometry.

3.1 Automotive Fuel-Injector Nozzles

Typical features:

Holes: ~0.1–0.2 mm

Multi-hole array

Excessive taper affects:

Spray cone angle

Droplet size and distribution

Fuel-air mixing uniformity

Combustion and emissions

Thus, small and consistent taper is critical.

3.2 Precision Filters / Sieves / Spinnerets

Used in filtration, chemical processing, and specialty fluid systems.

Taper directly influences:

Pressure drop & flow rate

Particle cut-off accuracy

Clogging tendency

High-end filter plates require near-cylindrical holes and well-controlled entrance shapes.

3.3 Inkjet Printheads / Microfluidic Chips

In inkjet nozzles:

Hole geometry determines droplet direction, volume, and velocity

In microfluidics:

Taper affects local flow resistance and mixing efficiency

Inconsistent taper can lead to:

Jet deviation

Satellite droplets

Poor repeatability between chips

These products often require near-zero taper + smooth walls.

3.4 Medical Nebulizers / Precision Spray Nozzles

Mist inhalers and drug nebulizers rely on precise micro-holes.

Poor taper control causes:

Inaccurate dosage

Shifts in droplet size distribution

Reduced therapeutic effect

3.5 Semiconductor / Display / MEMS Components

Examples:

Evaporation masks

Probe-card insulating substrates

MEMS vent holes

Taper impacts:

Pattern fidelity

Mechanical fit and alignment

Packaging characteristics

These industries increasingly adopt femtosecond micro-machining.

4. Advantages of Femtosecond Lasers in Zero-Taper or Small-Taper Processing

Compared with nanosecond, picosecond, EDM, mechanical drilling, and chemical etching, femtosecond lasers offer superior geometric control.

4.1 Cold Ablation: Minimal Heat, Minimal Melt

Femtosecond pulses deposit energy much faster than thermal diffusion:

Greatly reduced molten layer

Minimal entrance deformation

Fewer re-solidified particles on walls

Less micro-cracking in brittle materials (glass, sapphire, ceramics)

4.2 High Peak Power + Nonlinear Absorption

In transparent or difficult-to-machine materials:

Multiphoton absorption and avalanche ionization ensure efficient removal even when linear absorption is weak

Ablation occurs only at the focus, ideal for deep and narrow structures

With Bessel beams or dynamic focusing, depth-uniformity improves dramatically.

4.3 Excellent Compatibility with Bessel and Composite Beams

Combining femtosecond lasers with Bessel beams provides:

Long and stable DOF

Cold ablation → smooth and straight hole walls

Adjustable hole geometry (slightly converging, diverging, or cylindrical)

This combination is highly competitive for zero-taper applications.

4.4 Replacement Potential for Traditional Processes

Advantages over EDM, drilling, and chemical etching:

Works with metals, ceramics, glass, sapphire, polymers, composites

No tool wear → better consistency

Ideal for high-precision, small-batch production

Supports flexible and complex microhole designs

For many high-value micro-hole products, femtosecond solutions are rapidly gaining ground.

5. Application Areas Where Femtosecond Processing May Replace Traditional Methods

Examples of likely transitions:

Fuel-injector micro-holes

EDM → femtosecond + Bessel/composite beams

Goal: smaller taper, better repeatability, flexible hole-shape design.

High-precision filter plates / spinnerets

Chemical etching / mechanical punching → femtosecond array scanning

Goal: near-cylindrical holes, customized entrance profiles.

Microfluidic chips

Silicon/glass etching → femtosecond direct writing

Goal: fast iteration, 3D structures, zero-taper throttle holes.

Inkjet & medical nozzles

Goal: high-precision multi-layer holes, consistent spray performance.

Sapphire / ceramic micro-holes

Grinding / ultrasonic drilling → femtosecond Bessel machining

Goal: lower damage, higher speed, better geometry.

6. Conclusion: From “Accepting Taper” to “Designing Taper”

Laser micro-hole taper is not a random defect. It is a natural outcome of:

Gaussian beam structure

Limited depth of focus

Internal reflections

Material thermal response

Melt-ejection dynamics

To reduce or eliminate taper, one must optimize beam engineering, process strategy, and inspection, not simply tweak a single parameter.

In critical products—fuel injectors, precision filters, inkjet heads, microfluidics, medical nozzles, semiconductor/MEMS components—taper directly determines performance and reliability.

Femtosecond lasers, with cold ablation and compatibility with Bessel/composite beams, are becoming a powerful solution for zero-taper micro-machining and are poised to replace several traditional processes.

Ultimately, taper should be treated not as a flaw but as a design parameter. When taper can be controlled—or even engineered—laser micro-machining evolves from “making it” to truly “designing it.”