In an era defined by nanometer-level engineering and ultra-sensitive biological research, conventional tools often fall short. That’s where femtosecond lasers step in—not as an incremental improvement, but as a transformative technology reshaping precision manufacturing, medicine, and photonics.

By 2025, femtosecond laser systems have matured into versatile, industrial-grade tools capable of doing what no mechanical or thermal method can: processing materials with near-zero heat, sub-micron accuracy, and surgical control. Whether you’re etching circuits into sapphire, cutting transparent materials, or performing LASIK eye surgery, the femtosecond laser has become an irreplaceable part of the toolkit.

In this article, we’ll explore what makes a femtosecond laser different, who the key users are in 2025, and how to choose the best system for your needs.

1. What Is a Femtosecond Laser?

A femtosecond laser emits pulses of light that last on the order of 10⁻¹⁵ seconds—literally one quadrillionth of a second. To put that in perspective, light travels less than a human hair’s width in that time.

This incredibly short pulse duration creates extreme peak powers (often in the megawatt to gigawatt range) without requiring high average power. The result? A laser that can remove or modify material before heat has time to spread.

This “cold ablation” process is what sets femtosecond lasers apart. They allow for:

Non-thermal machining (no melting or burrs)

High-precision micro-drilling, cutting, and structuring

Sub-surface modification in transparent materials

Biological tissue interaction with minimal collateral damage

2. Why 2025 Is the Year of Femtosecond Lasers

As of 2025, femtosecond laser adoption has surged, and not just in research labs. These systems are now vital tools in:

Semiconductor processing (e.g., wafer dicing, via drilling, OLED cutting)

Medical devices and ophthalmology (e.g., corneal flap creation, catheter marking)

Precision micromachining (e.g., stents, microfluidic chips, optical components)

High-resolution 3D printing / multiphoton polymerization

Thin-film patterning for photovoltaics and sensors

With the global push for miniaturization, higher precision, and biocompatibility, the femtosecond laser has become the gold standard for non-thermal processing.

3. How Femtosecond Lasers Work

Femtosecond lasers typically use a mode-locked oscillator to generate ultrafast pulses, which are then amplified in systems like chirped pulse amplification (CPA) setups. Key components of a 2025 femtosecond laser system include:

Ultrashort pulse oscillator

Pulse stretcher/compressor

Beam delivery optics and scanning systems

Cooling and vibration isolation modules

High-resolution motion stages (for micromachining)

Computerized control interface (for timing, focusing, pulse shaping)

Modern femtosecond lasers operate in a range of wavelengths—from infrared (1030 nm Yb-doped systems), to green (515 nm), and even UV (343 nm) via harmonic generation—depending on the application and material interaction.

4. Key Advantages of Femtosecond Lasers

| Feature | Benefit |

|---|---|

| Ultrashort Pulses | Material is ablated before heat diffuses → no heat-affected zone (HAZ). |

| High Precision | Can structure materials down to sub-micron features. |

| Material Flexibility | Metals, ceramics, polymers, transparent materials (glass, sapphire). |

| Biological Compatibility | Minimal thermal damage makes it ideal for medical procedures. |

| Clean Edges | No recast layer, burrs, or debris—suitable for optical-grade finishes. |

| 3D Machining | Able to write features inside transparent materials. |

These features make femtosecond lasers uniquely capable of solving manufacturing problems where traditional lasers (ns or ps pulse width) cause micro-cracks, melting, or residual stress.

5. 2025 Best Femtosecond Laser Use Cases

Medical and Ophthalmic Surgery

Used in LASIK procedures to create corneal flaps with micron precision. Also used for microfluidic channel fabrication in lab-on-chip diagnostics.

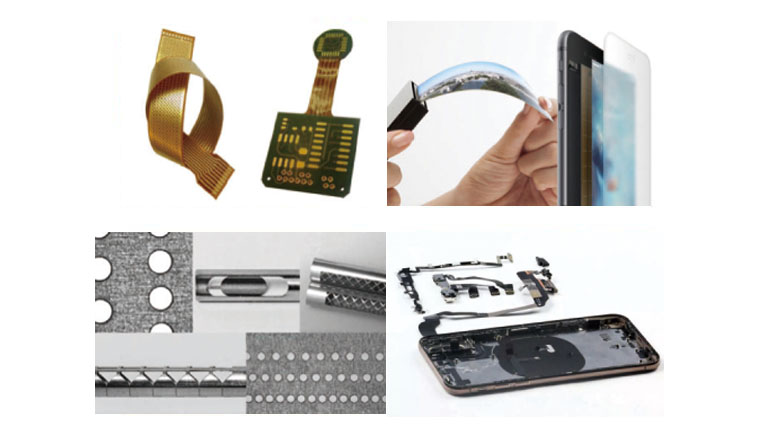

Electronics and Semiconductors

Cleanly drills microvias in PCBs and flex circuits, and cuts OLED displays without damaging adjacent pixels or layers.

High-Value Material Processing

Cuts sapphire, diamond, and ceramics—materials traditionally hard to process without fracture.

Glass and Transparent Polymer Structuring

3D inscription of waveguides, lenses, and internal cavities in transparent substrates.

3D Nano-Fabrication

Used in two-photon polymerization for printing nano-structures in biomedical or photonic applications.

6. What to Look for in a Femtosecond Laser System

When selecting the best femtosecond laser for your 2025 needs, here are some key factors to consider:

| Parameter | Why It Matters |

|---|---|

| Pulse Duration | 200 fs or less is ideal for most “cold” applications. |

| Average Power & Repetition Rate | High throughput for production lines. |

| Beam Quality (M² ~ 1.1) | Ensures tight, focused spots. |

| Wavelength Options | Infrared for metals, green/UV for transparent materials. |

| Integration | Ease of integration with scanners, motion systems, and CAD/CAM. |

| Stability & Uptime | Industrial systems must run continuously with minimal maintenance. |

| Control Interface | User-friendly software and programmable APIs. |

7. Future Trends in Femtosecond Laser Technology

The femtosecond laser landscape is evolving rapidly. Key trends for 2025 and beyond include:

Higher average powers with shorter pulses (enabling faster processing)

Green and UV femtosecond systems becoming more affordable

Beam shaping and adaptive optics for better energy control

AI-driven process optimization and real-time feedback

Miniaturized femtosecond modules for integration in robotic arms or lab benches

Multi-beam systems for parallel processing and higher throughput

These innovations will further solidify femtosecond lasers as core tools in Industry 4.0, medical robotics, and nano-fabrication.

Conclusion

The femtosecond laser is more than a technological marvel—it is a production enabler. In 2025, femtosecond systems are no longer restricted to elite labs or research institutions. They’re now powering cleanrooms, production floors, medical operating rooms, and advanced R&D across the world.

Whether you’re in precision micromachining, photonics, electronics, or biomedical engineering, choosing the best femtosecond laser in 2025 can give you a real edge—literally and figuratively.

Fast, cold, and incredibly precise—femtosecond lasers are shaping the future one ultrashort pulse at a time.