In plastic product manufacturing, blue plastic materials are widely used in industries such as electronics, medical devices, toys, and packaging due to their attractive appearance and broad application range. Thanks to its high precision, high efficiency, and eco-friendly processing, the UV laser marking machine has become an ideal solution for marking blue plastic, delivering clear and permanent marks while preserving the original material properties and surface quality.

Key Advantages of UV Laser Marking on Blue Plastic

The UV laser marking machine offers significant advantages when applied to blue plastic materials. Compared with infrared laser marking machines, UV lasers operate at a shorter wavelength (typically 355 nm), allowing a much smaller focused spot size and micron-level marking accuracy.

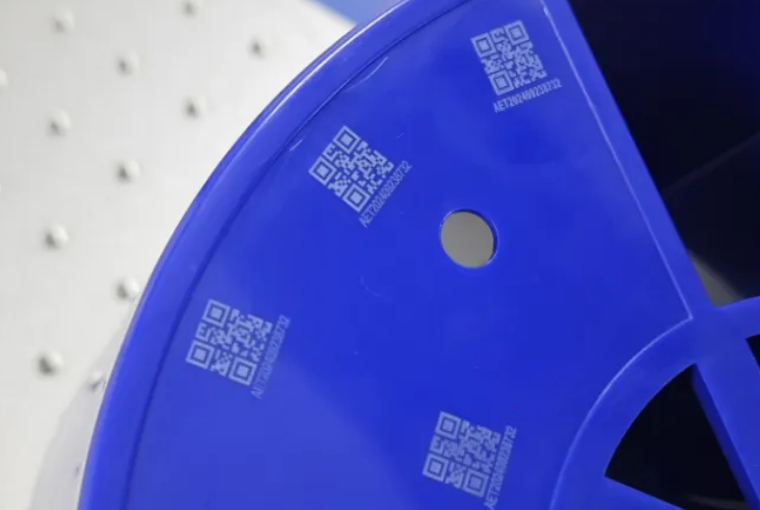

This makes it possible to mark fine text, QR codes, logos, and serial numbers on blue plastic surfaces with smooth edges and no burrs, avoiding common issues such as color bleeding or blurred contours. These features are especially important for products with high aesthetic requirements.

In addition, UV laser marking is a cold processing method, producing a very small heat-affected zone. This prevents deformation, yellowing, or carbonization of blue plastic materials, making it particularly suitable for PC, ABS, PP, and other commonly used blue plastics.

Process Tips for Achieving Optimal Marking Results

To achieve high-quality marking results on blue plastic, several key process parameters must be carefully controlled.

Laser Power:

Blue plastic is highly sensitive to UV laser energy. Excessive power may damage the surface, while insufficient power results in low contrast. In most cases, setting the power to 20%–50% is recommended, with fine adjustments based on material type and thickness.Marking Speed:

Excessively high speed can reduce clarity, while overly slow speed may cause localized overheating. A typical marking speed range of 300–800 mm/s, combined with multiple-pass marking, helps improve contrast and consistency.Focus Position:

Accurate focusing is essential. The laser focal point should be precisely positioned on the plastic surface to avoid distortion, uneven depth, or inconsistent marking quality.

Typical Applications of UV Laser Marking on Blue Plastic

The UV laser marking machine is widely used across multiple industries when working with blue plastic components:

Electronics Industry:

Marking product models, serial numbers, and manufacturing dates on blue plastic housings and connectors for traceability.Medical Devices:

Printing batch numbers and sterilization marks on blue plastic parts, ensuring compliance with medical regulations.Toys and Consumer Goods:

Creating customized patterns and brand logos on blue plastic products to enhance product identity and market appeal.

UV laser marking requires no consumables, supports environmentally friendly production, and produces durable, abrasion-resistant marks that withstand daily wear and environmental exposure.

Why UV Laser Marking Outperforms Traditional Methods

Compared with traditional processes such as screen printing or inkjet coding, UV laser marking machines offer superior marking quality, higher production efficiency, and lower overall operating costs when processing blue plastic materials. The permanent markings eliminate concerns about fading, peeling, or ink migration.

With continuous technological advancements, UV laser marking machines are becoming compatible with an even wider range of blue plastic materials, delivering more precise, stable, and efficient marking solutions for modern manufacturing.

Conclusion: Enhancing Product Value with UV Laser Marking Technology

As demand for high-quality plastic products continues to grow, UV laser marking on blue plastic has become an essential technology for manufacturers seeking precision, consistency, and sustainability. By selecting the right UV laser marking machine and optimizing process parameters, businesses can significantly improve product appearance, traceability, and brand recognition.

If you are looking to enhance your blue plastic marking process with reliable and advanced solutions, a professional UV laser marking machine will be a long-term investment that boosts both production efficiency and product competitiveness—helping your brand stand out in an increasingly demanding global market.

Contact Us for a Free Sample & Professional Laser Solution

If you are looking for a reliable laser engraving machine solution, feel free to contact us.

We provide free sample testing, professional application evaluation, and customized laser system recommendations based on your material, marking requirements, and production needs.

Our experienced technical team will help you choose the most suitable fiber laser engraving machine, optimize engraving parameters, and ensure stable, high-quality results on metal and plastic materials.

Contact us today to get a free sample engraving and a complete laser processing solution.