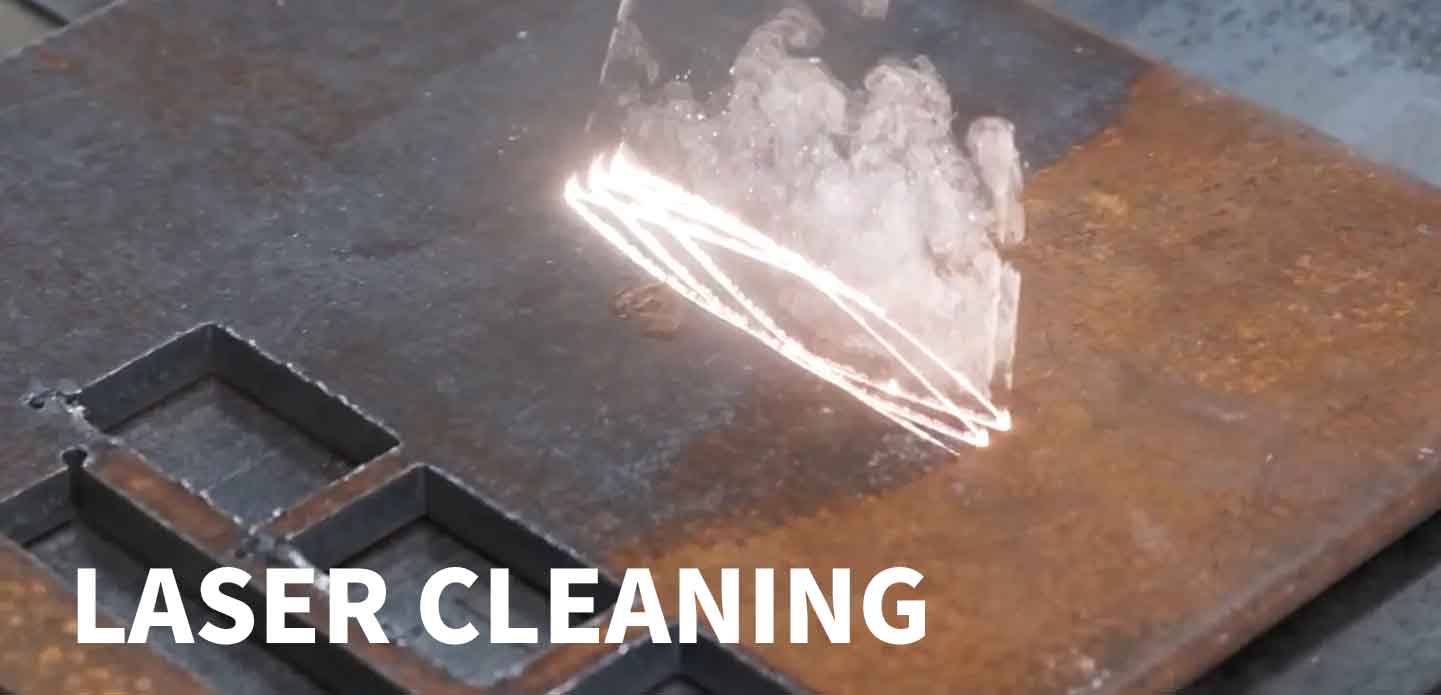

The application of laser cleaning technology in the new energy industry is gradually deepening. With its advantages of high precision, zero pollution, no consumables, high efficiency, and easy automation, it has become a key technological solution in battery manufacturing, photovoltaic module maintenance, and wind power equipment upkeep. In 2024, China’s production and sales of new energy vehicles continued to grow at a remarkable pace, maintaining its global leadership for the tenth consecutive year. Meanwhile, newly installed capacity of photovoltaic and wind power increased by 28% and 6% respectively, highlighting the strong momentum of green energy transformation.

Laser Cleaning Applications in the New Energy Sector

Full-Process Cleaning in Lithium Battery Manufacturing

Pre-coating Cleaning of Electrode Sheets: Removes oil stains, oxide layers, and particles from aluminum and copper foil surfaces to ensure uniform coating of electrode materials and avoid the risk of internal short circuits. Traditional wet cleaning methods tend to leave chemical residues, while laser cleaning enables “non-contact” processing and improves electrode consistency.

Pre-welding Surface Treatment: For components such as battery tabs, sealing nails, and busbars, laser cleaning rapidly removes oxide layers and contaminants, enhances welding strength, and reduces false welds. For example, in power battery module welding, laser cleaning can reduce the weld defect rate to below 0.1%.

Battery Pack Assembly Cleaning: Cleans oxidation layers on battery enclosures, tray welds, and sealing glue tracks, enhancing glue adhesion and prolonging battery pack lifespan.

Flat Wire Motor Copper Wire Cleaning: Removes insulating lacquer layer from flat copper wires without damaging their surface. This precise treatment ensures the conductivity of copper wires remains intact, supporting reliable motor performance.

Battery Repair: Precisely removes the packaging material of aged batteries to facilitate recycling and reuse.

Photovoltaic Module Maintenance and Cleaning

Cleaning of Photovoltaic Glass Surfaces: Removes dust, bird droppings, organic pollutants, etc., from the surface of photovoltaic glass to improve light transmittance. Traditional cleaning relies on chemical agents or high-pressure water jets, which may damage the glass coating. Laser cleaning offers micron-level precision and preserves coating integrity.

Frame and Bracket Treatment: Eliminates oxide layers on aluminum alloy frames to prevent corrosion and extend bracket lifespan, enhancing subsequent coating or welding effectiveness.

P4 Laser Edge Cleaning: Used for pre-packaging cleaning processes.

Wind Power Equipment Maintenance

Blade Surface Cleaning: Removes dust, oil, and biological deposits from the surface of blades to restore aerodynamic performance. Traditional cleaning often requires high-altitude operations with low efficiency and safety risks, while laser cleaning can be paired with drones or robots for remote operation.

Gearbox and Bearing Degreasing: Rapidly eliminates oil and carbon buildup from gearboxes, reducing maintenance time and improving equipment reliability.

Tower Anticorrosion Treatment: Removes metal surface oxides before welding to enhance the adhesion of anticorrosion coatings.

Hydrogen Fuel Cell Surface Cleaning

Bipolar Plate Treatment: Removes oxide layers and impurities from stainless steel or graphite bipolar plates to improve conductivity and corrosion resistance.

Membrane Electrode Assembly (MEA) Cleaning: Eliminates residual particles from the production process to prevent damage to the proton exchange membrane.

Nuclear Equipment Decontamination

Radioactive Contaminant Removal: Laser ablation of radioactive deposits (such as uranium and plutonium oxides) from metal surfaces in nuclear facilities reduces radiation exposure to personnel.

Decommissioned Equipment Handling: Efficiently removes contamination layers from nuclear waste containers to facilitate safe recovery.

Lithium Battery Laser Cleaning Equipment Market

The energy crisis has accelerated the development of new energy vehicles. As the power source of EVs, the demand for new energy power batteries is growing rapidly. According to GGII forecasts, by 2030, global demand for power batteries will exceed 1100 GWh—an increase of 10 times compared to current levels. According to GGII data, the market size of laser cleaning equipment for lithium batteries reached 1.27 billion CNY in 2023 and is expected to exceed 3 billion CNY by 2025, with a compound annual growth rate of 54%.

Future Prospects of Laser Cleaning in the New Energy Sector

According to QYResearch forecasts, the global laser cleaning market size will exceed 6 billion CNY by 2030, with the new energy sector accounting for more than 40%. With the mass production of solid-state batteries and perovskite photovoltaics, laser cleaning is expected to experience explosive growth. In the future, multi-technology integration will prevail: laser cleaning will be deeply integrated with AI vision inspection and robotic path planning to enable real-time monitoring and adaptive adjustment of the cleaning process.

Device miniaturization and portability will be key trends. For scenarios such as distributed photovoltaic power stations and home energy storage systems, handheld or vehicle-mounted laser cleaning equipment will be developed to enhance maintenance flexibility.

The mass production of 4680 large cylindrical lithium batteries will bring new process demands. The widespread use of composite current collectors (PET-copper foil) will create demand for ultra-precise cleaning. Meanwhile, the EU Battery Regulation is accelerating the adoption of green manufacturing technologies, providing broader application opportunities for laser cleaning.

With breakthroughs in domestic laser source technology, equipment costs are expected to decline by 30%–50%, promoting the widespread adoption of laser cleaning in small and medium-sized new energy enterprises.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。