On May 26, 2025, the 34th China International Glass Industrial Technical Exhibition was grandly held at the China International Exhibition Center (Shunyi Hall). JCZ (Beijing JCZ Technology Co., Ltd.) showcased its independently developed Infinite Field Linkage – Intelligent Control System and comprehensive solutions for the glass industry at the exhibition.

The exhibits focused on key pain points in glass processing, offering customers high-precision and high-efficiency intelligent solutions. With cutting-edge technological achievements and practical application value, JCZ attracted numerous industry professionals for in-depth communication.

Among the highlights was JCZ’s self-developed Infinite Field Linkage – Intelligent Control System, designed for applications such as glass film removal and sandblasting. This solution offers a new approach for laser processing of brittle materials and drew significant attention at the event. Through live demonstrations and technical explanations, the system’s core strengths were fully presented. A simulated glass processing scenario vividly demonstrated the system’s stable performance under complex processes.

Core Product Analysis

How Does the “Infinite Field Linkage” System Address Industry Pain Points?

— Fully Closed-Loop Control Leading Industry Upgrades

In the field of glass processing, traditional stitching methods are limited by galvanometer scanning field sizes, often causing alignment errors at the seams. This results in material waste and reduced production efficiency. The Infinite Field Linkage – Intelligent Control System launched by JCZ features real-time fully closed-loop control of the laser, galvanometer, and motion platform, supporting multi-axis galvanometer linkage strategies. It breaks through the physical limitations of traditional processing, achieving large-format, seamless laser processing while effectively avoiding stitching issues.

This system integrates a high-performance control card with mainstream laser and galvanometer control functions. With axis precision reaching ±5μm and galvanometer calibration accuracy up to ±10μm, the final processing accuracy can reach ±20μm. Additionally, by optimizing the sorting algorithm and path planning, the system significantly improves data processing efficiency. Users can operate it without parameter adjustments, as it intelligently adapts to various design files, greatly lowering the usage threshold.

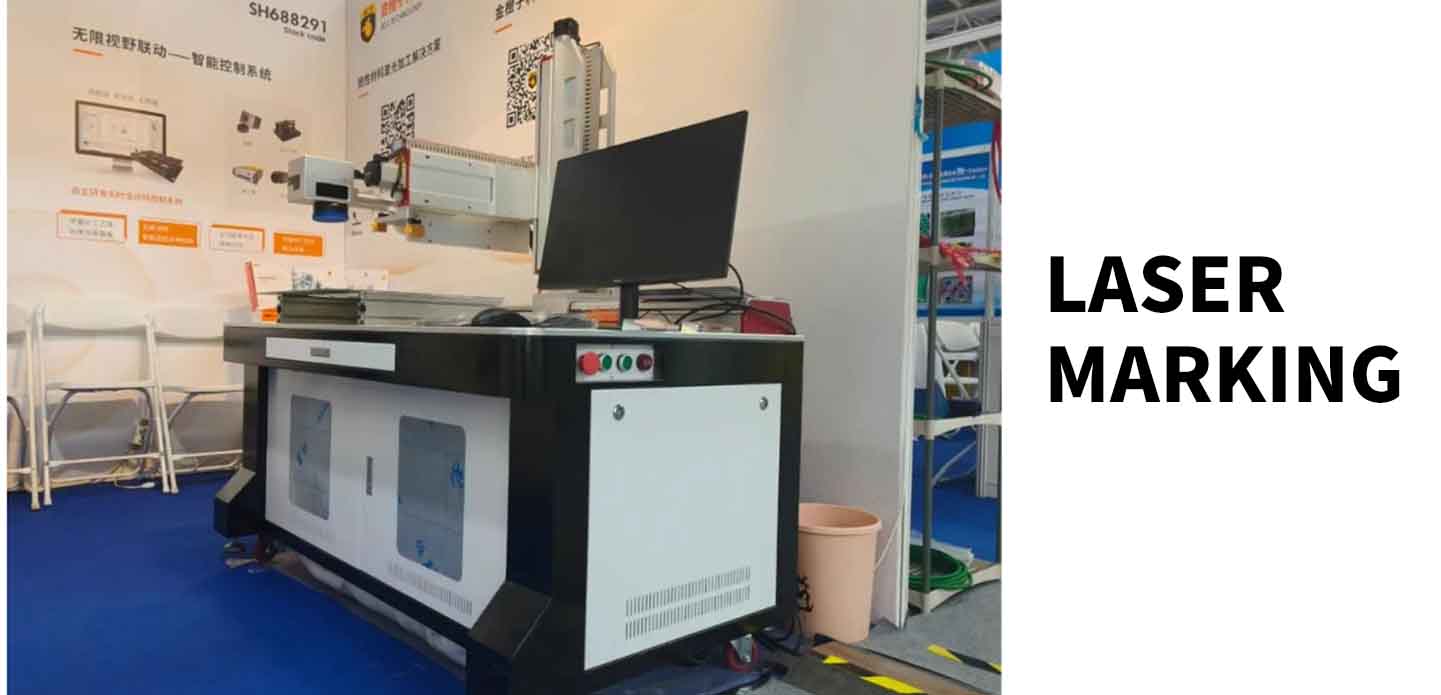

Full-Chain Solutions

To meet the diverse demands of the glass industry, JCZ presented comprehensive solutions covering marking, film removal, internal engraving, drilling, and cutting at the exhibition. These solutions not only enhance the efficiency and quality of glass product processing but also fulfill market needs for personalization and customization.

At JCZ’s booth, visitors could experience firsthand the innovative application of laser technology in processing brittle materials. We remain committed to laser processing technology R&D and will continue to launch more adaptable control systems and solutions tailored to industry needs, helping the glass industry achieve high-quality development.

Company Profile

Beijing JCZ Technology Co., Ltd. (JCZ, Stock Code: 688291), founded in 2004, focuses on R&D of control software, systems, and components for the laser industrial processing sector. JCZ is recognized as a “Little Giant” enterprise specializing in precision and innovation by the Ministry of Industry and Information Technology, as well as by Beijing Municipality. The company is also a National High-Tech Enterprise certified by the Beijing Science and Technology Commission and a strategic partner in Fengtai District’s “Doubling and Cooperation” program.

Looking ahead, JCZ will continue to drive technological innovation and remain dedicated to building a robust “beam transmission and control” technology platform. We aim to provide integrated motion-control solutions and value-added services for system integrators and end-users worldwide, striving to become a competitive and influential expert in beam transmission and control.