In the field of laser processing, JCZ control systems have become the preferred solution across various industries due to their outstanding performance and wide range of applications. Building upon its deep expertise in laser marking (as detailed in the previous article), JCZ Technology has extended its technological strengths into applications such as precision and brittle material cutting, static and flying welding, additive manufacturing, and large-format processing. These capabilities provide end-to-end solutions for industries including automotive, aerospace, medical, and consumer electronics, showcasing JCZ’s comprehensive ability to empower all scenarios and its significant advantages across different sectors.

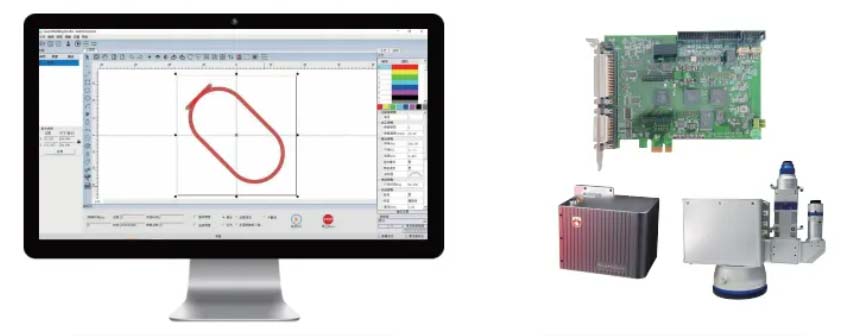

Cutting Control Systems

— Precision Cutting Empowering Diverse Industries

JCZ’s cutting control system is a self-developed solution tailored for fiber laser cutting. Its core product suite, featuring CutMaker software and the MCS2 control card, integrates excellent motion control algorithms and process handling capabilities. This system is user-friendly, feature-rich, stable, reliable, and powerful, offering customers a complete laser cutting solution.

System Advantages

Ultra-fast glass cutting with PSO function, unrestricted by shapes, ensures equidistant laser output for enhanced cutting quality

Cross energy avoidance to protect materials and prevent energy accumulation at cutting intersections

Integrated cutting and splitting significantly boosts processing efficiency

Off-axis visual positioning enables highly accurate processing

Application Scenarios

Widely used in advertising, automotive manufacturing, 3C electronics, and medical equipment industries, particularly excelling with high-precision and brittle materials.

Welding Control Systems

— Intelligent Welding, High Precision and Efficiency

System Advantages

High Efficiency:

Supports multi-file, multi-station processing, automatic optimization of multi-segment welding sequences, and optimized galvo transitions

High Quality:

Real-time control of frequency, duty cycle, and pulse width, precise power waveform output, and stable dual-beam analog adjustment

High Stability:

Offline execution of welding paths and closed-loop control of galvo positions

Application Scenarios

Extensively applied in lithium battery, automotive, and 3C electronics industries, delivering efficient welding solutions for a variety of applications.

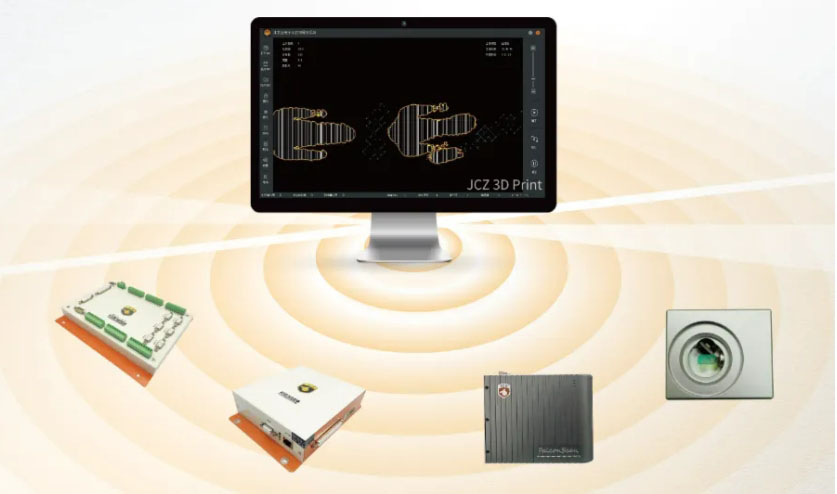

3D Printing Control Systems

— Innovative Manufacturing, Expanding Boundaries

The JCZ 3D Print series control cards and software are independently developed systems designed specifically for the additive manufacturing industry. Covering SLA, SLM, SLS, and other technologies, the system includes control software, axis control cards, and laser galvo control cards. The 2.0 version of the control software has been refined over years and is highly regarded in the market for its proprietary algorithms.

System Advantages

Integrated Software and Hardware:

Unique hardware design solves start/end defects caused by excessive laser intensity

Variable Power, Spacing, and Layer Thickness Scanning:

Greatly improves processing efficiency and reduces deformation

Localized Skin Recognition Technology:

Supports processing for upper/lower skin layers and skin contours

Localized Thin-Wall Filling:

Identifies and compensates areas unreachable by standard filling, fully solving filling gap issues

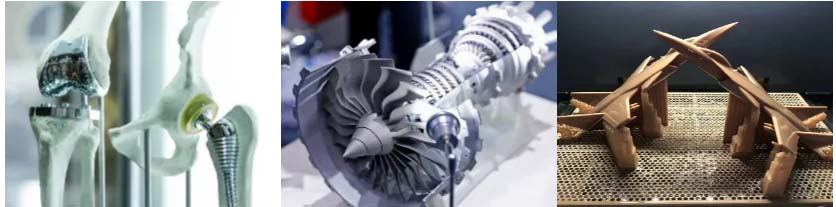

Application Scenarios

Widely applied in medical, aerospace, and mold design and manufacturing sectors, offering comprehensive solution services to users.

Infinite Field Linkage – Intelligent Control System

— Full Closed-Loop Control Leading Industrial Upgrades

The Infinite Field Linkage – Intelligent Control System is JCZ’s independently developed real-time full closed-loop control system for laser, galvo, and motion platforms. It supports various galvo-motion axis linkage schemes, effectively solving challenges in large-format laser processing such as low precision, poor process results, difficult debugging, and long processing times. Depending on client needs, the system offers two product configurations: Zeus_V1 card with a development kit or Zeus_V1 card with Zeus software.

System Advantages

High Precision:

With motion axis precision within ±5µm and galvo calibration within ±10µm, the final processing precision reaches ±20µm

High Efficiency:

Supports multiple sorting algorithms for rapid processing of large datasets

Full Laser and Galvo Control:

Zeus_V1 card integrates mainstream laser and galvo control functionalities, eliminating the need for adapter cards

High Drawing Compatibility:

Intelligently adapts to various drawings without parameter tuning, lowering the usage threshold

Application Scenarios

Applicable in PCB cutting and etching; large-format glass film removal, sandblasting, drilling; ITO film precision processing; stainless steel elevator panel treatment, metal surface cleaning; catheter and implantable device micro-processing, among others.

JCZ control systems empower diverse industries by offering a broad product line and customizable solutions to meet individual needs, continuously driving technological innovation and upgrades. Looking ahead, we will continue to provide premium “drive-control integrated” products and complete solutions. We look forward to collaborating with partners across industries to explore the infinite possibilities of laser processing together.