Advanced Jewelry Laser Welder for Modern Manufacturing

A professional jewelry laser welder is an essential tool for precision welding in jewelry manufacturing and repair. Compared with traditional soldering methods, laser welding provides high accuracy, minimal heat input, and excellent joint quality. A modern jewelry laser welder enables manufacturers and workshops to achieve clean, strong, and aesthetically pleasing welds on precious metals.

Fiber Laser Welder Technology for Superior Welding Quality

A fiber laser welder uses a highly stable fiber laser source to deliver concentrated energy directly to the welding point. This technology ensures deep penetration, fine weld seams, and minimal distortion. As a result, a fiber laser welder is widely used in applications that require precision welding, including gold, silver, platinum, stainless steel, and titanium components.

Laser Fiber Welding Machine with Precise Energy Control

A high-performance laser fiber welding machine offers precise control over laser power, pulse frequency, and welding duration. This level of control allows operators to adjust welding parameters for different materials and thicknesses. With consistent output and excellent beam quality, a laser fiber welding machine ensures repeatable welding results in both small-scale workshops and industrial production environments.

Jewelry Welding Machine for Delicate and Complex Designs

A dedicated jewelry welding machine is specifically designed to handle delicate structures, thin materials, and complex jewelry designs. Whether repairing rings, chains, clasps, or micro components, a jewelry welding machine enables non-contact welding without damaging surrounding areas. This makes it ideal for high-end jewelry repair and custom manufacturing.

Non-Contact and Low Heat Advantages of a Jewelry Laser Welder

One key advantage of a jewelry laser welder is its non-contact welding process, which minimizes thermal impact on the workpiece. The focused laser beam reduces the heat-affected zone, preventing discoloration, deformation, or cracking. This low-heat welding capability is especially important for gemstone-set jewelry and fine details.

High Efficiency and Productivity with a Fiber Laser Welder

A fiber laser welder supports fast welding speeds and high production efficiency. With minimal post-processing required, manufacturers can significantly reduce labor time and improve throughput. When integrated with modern control systems, a fiber laser welder delivers consistent performance for both batch production and customized orders.

Wide Material Compatibility of a Laser Fiber Welding Machine

A versatile laser fiber welding machine can weld a wide range of metals commonly used in jewelry and precision manufacturing. From precious metals to alloys, the laser fiber welding machine ensures strong and reliable joints without the need for filler materials. This versatility expands application possibilities across jewelry, electronics, medical devices, and precision parts manufacturing.

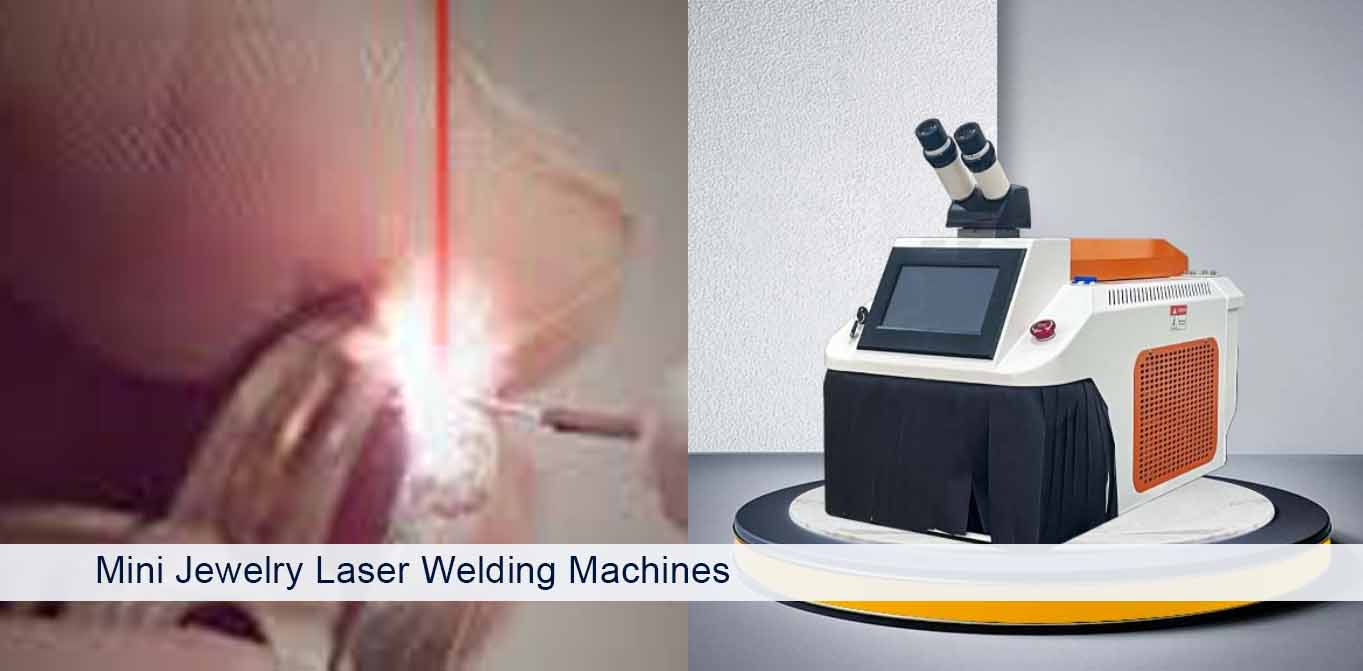

User-Friendly Design of a Jewelry Welding Machine

A modern jewelry welding machine features an intuitive control interface, real-time visual monitoring, and ergonomic design. These features reduce the learning curve for operators while ensuring precise welding control. Compact structure and low maintenance requirements make a jewelry welding machine suitable for retail workshops, factories, and service centers.

Cost Efficiency and Long-Term Value of a Jewelry Laser Welder

Investing in a jewelry laser welder offers long-term cost benefits through reduced material waste, lower maintenance costs, and improved product quality. Compared with traditional welding equipment, laser systems provide higher reliability and longer service life, making them a cost-effective solution for professional jewelry production.

Choosing the Right Fiber Laser Welder for Your Business

Selecting the right fiber laser welder depends on factors such as material type, welding thickness, production volume, and precision requirements. A properly configured laser fiber welding machine can significantly enhance product quality and operational efficiency. Choosing a reliable jewelry welding machine helps businesses stay competitive in the global jewelry market.

Contact us to get the latest solutions for your needs. We also offer free sample testing services to ensure the best results before your production.