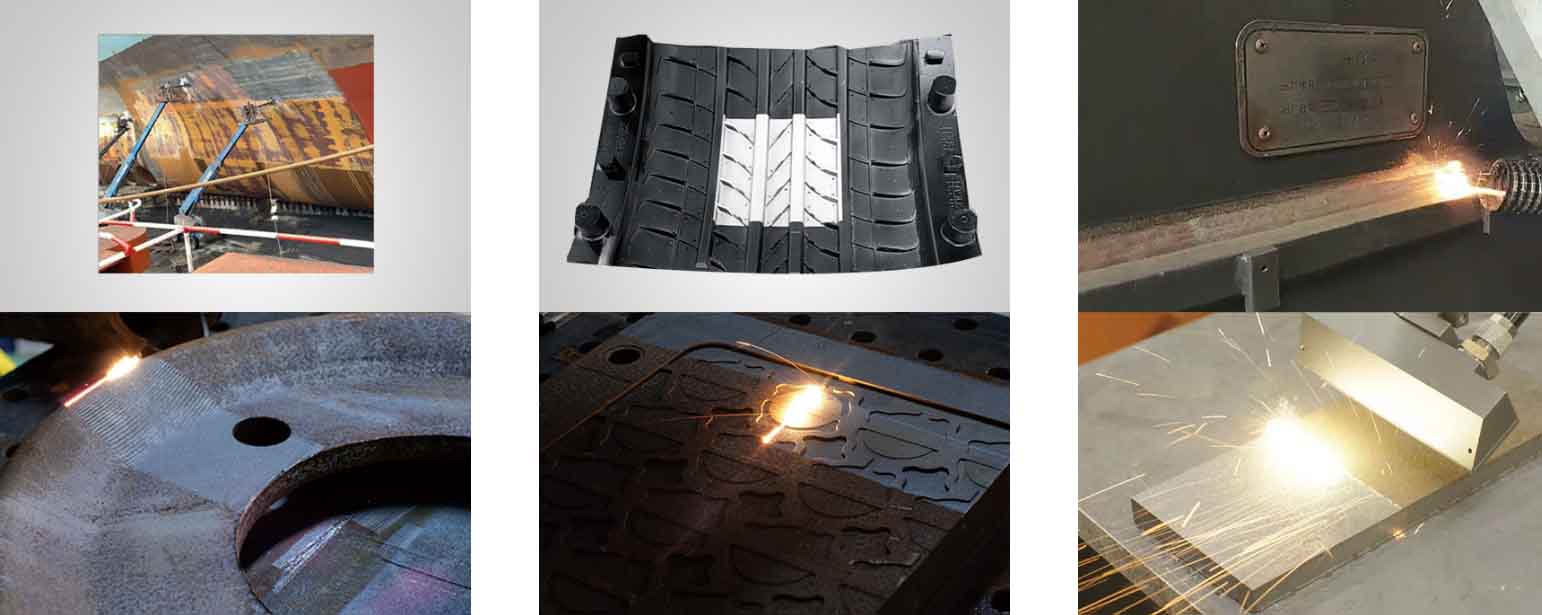

In modern industrial maintenance and surface preparation, traditional methods like sandblasting, chemical stripping, and grinding are quickly being replaced by a cleaner, safer, and more efficient technology: the laser cleaning machine. Whether you’re dealing with corroded metal, flaking paint, or oxidation, laser rust removal and laser paint removal offer a non-contact, eco-friendly alternative that saves time and preserves surface integrity.

What is a Laser Cleaning Machine?

A laser cleaning machine uses a high-powered laser beam to remove contaminants, oxides, rust, grease, or paint from surfaces without damaging the base material. Unlike mechanical or chemical methods, laser cleaning is a dry, precise, and environmentally friendly process.

Key Features:

Non-abrasive: No damage to the substrate

Precision-controlled: Ideal for sensitive components

Chemical-free: Safe for users and the environment

Low maintenance: No consumables or media required

Automatable: Suitable for robotic and CNC integration

Laser cleaning systems are now widely used in aerospace, automotive, shipbuilding, railways, and restoration industries.

Laser Rust Removal: Clean Metals Without Grinding

Rust can weaken metal structures, degrade performance, and ruin aesthetics. Traditional rust removal often involves grinding or sandblasting, which is time-consuming and potentially harmful. In contrast, laser rust removal provides a fast and contactless way to eliminate rust layers while preserving the integrity of the underlying metal.

Applications:

Industrial machinery restoration

Automotive part maintenance

Railway and ship hull refurbishment

Pipeline and structural steel cleaning

Laser rust removal is particularly useful for precision equipment and historic restoration projects where surface preservation is essential.

Laser Paint Removal: Stripping Without the Mess

Removing old or damaged paint is often messy, toxic, and labor-intensive. Laser paint removal changes that. By selectively ablating the paint layer without heating or damaging the base material, laser systems deliver precise and controlled paint stripping—even from complex or delicate surfaces.

Benefits:

No masking or surface preparation needed

Removes paint in layers or patterns (great for selective stripping)

Compatible with metal, composites, stone, and more

Ideal for aerospace, auto, and military repainting workflows

Whether you’re refurbishing old machinery or preparing aerospace components for re-coating, laser paint removal ensures a clean, residue-free surface every time.

Why Choose a Laser Cleaning Machine?

| Feature | Advantage |

|---|---|

| Environmentally Friendly | No chemicals or solvents involved |

| Efficient & Fast | Removes rust or paint in seconds |

| No Consumables | Reduces operating cost |

| Highly Versatile | Works on metal, stone, concrete, and more |

| Long-Term Investment | Durable components, minimal maintenance |

Compared to traditional cleaning methods, a laser cleaning machine offers long-term savings, safer operation, and greater precision.

Conclusion

Whether you need laser rust removal for corroded equipment or laser paint removal for surface reconditioning, investing in a laser cleaning machine offers unmatched benefits in speed, safety, and quality. With zero chemicals, no abrasion, and minimal environmental impact, laser cleaning is quickly becoming the preferred method in industries where surface integrity and precision matter most.

Explore our range of portable, handheld, and automated laser cleaning systems today—and bring your surfaces back to life with the power of light.