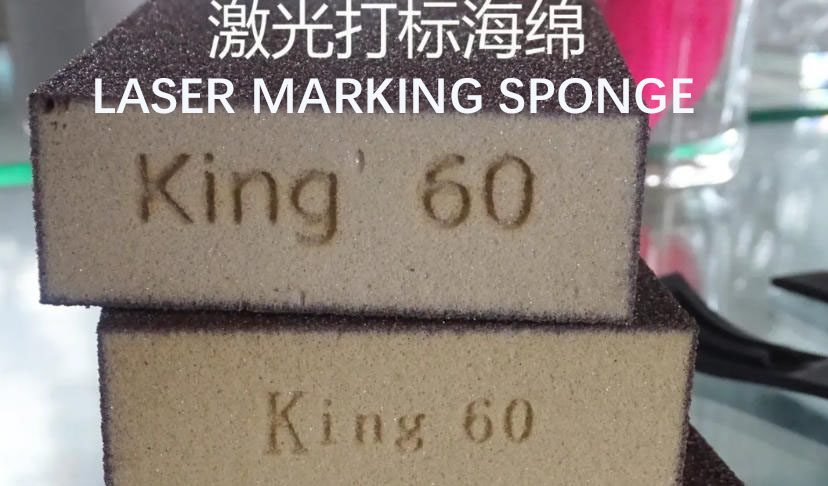

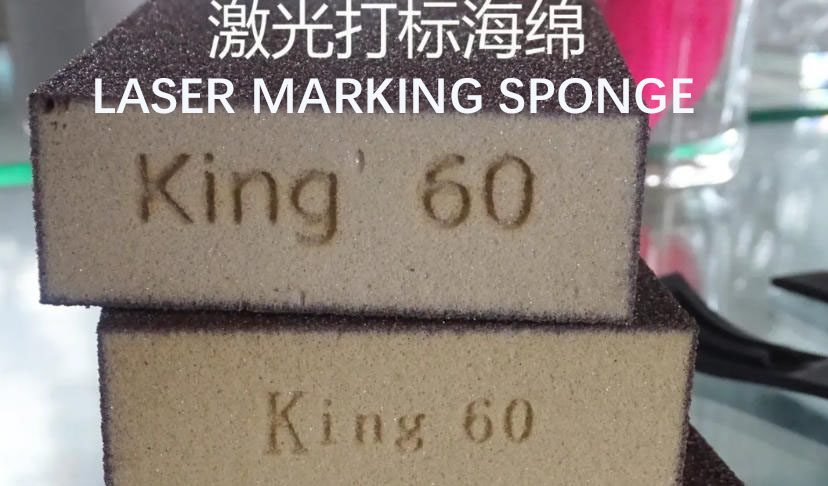

Among various materials used in marking applications, sponge stands out due to its unique soft and porous texture, which requires a specialized marking technique. Laser marking machines demonstrate excellent performance when processing sponge materials, offering high precision, efficiency, and stability.

During operation, a laser marking machine uses a high-energy laser beam to act on the surface of the sponge. The principle is simple: the laser generates instant high temperatures that vaporize or chemically alter the surface layer of the sponge, forming a clear and permanent mark. For example, a CO₂ laser marking machine emits a 10.6 μm wavelength laser beam, which is precisely focused through the optical system onto the sponge surface. As a non-contact process, laser marking does not compress or abrade the sponge, effectively avoiding deformation issues often caused by traditional mechanical marking methods.

In terms of marking quality, laser machines can achieve clear, sharp, and highly detailed marks on sponge materials. Whether it is simple text, intricate patterns, or small QR codes, the laser can produce accurate and consistent results. The marking depth can be customized according to application needs by adjusting laser power, pulse width, and marking speed. Additionally, laser markings are highly durable—unaffected by daily use, friction, or environmental conditions—and remain sharp and readable over time.

From a production perspective, modern laser marking machines are equipped with advanced galvanometer scanning systems, enabling fast and stable operation even under high-volume production demands. They significantly improve productivity while maintaining consistent marking quality. The system is easy to operate, allowing users to design and modify marking content directly through software with great flexibility.

In summary, laser marking machines offer a high-quality and efficient solution for sponge material marking. They are widely used in the production of makeup sponges, sponge toys, packaging inserts, and other sponge-based products, greatly enhancing product branding and manufacturing efficiency.

If you are looking for precise, high-performance marking solutions for sponge materials or other soft substrates, laser marking technology is one of the most reliable options available today. To explore more professional insights, application cases, and advanced laser processing solutions, feel free to visit our website and discover how laser marking can upgrade your manufacturing workflow.