As industries demand more sophisticated and versatile marking solutions, the MOPA fiber laser has emerged as a powerful and adaptable laser source for a wide range of applications. Compared to traditional Q-switched lasers, the MOPA fiber laser marking machine offers greater control over pulse width and frequency—enabling high-contrast, burr-free, and heat-free markings on various materials.

Whether you’re in electronics, medical devices, automotive parts, or luxury branding, understanding MOPA laser technology and its advantages is key to making the right investment.

What Is a MOPA Fiber Laser?

MOPA stands for Master Oscillator Power Amplifier—a laser architecture that separates pulse generation and amplification stages. This structure allows for fine-tuned control of laser parameters like:

Pulse width (adjustable from 2ns to 500ns+)

Repetition frequency (1kHz – 1MHz)

Peak power and pulse energy

This makes the MOPA fiber laser a more flexible and powerful laser source compared to conventional fiber lasers.

Why Choose a MOPA Fiber Laser Marking Machine?

A MOPA fiber laser marking machine is especially suited for high-precision, contrast-rich marking and delicate surface processing. It offers excellent performance in applications where thermal damage must be avoided or where high-quality color and deep engraving are needed.

Key Advantages:

No burn marks on plastics, especially black or white plastic

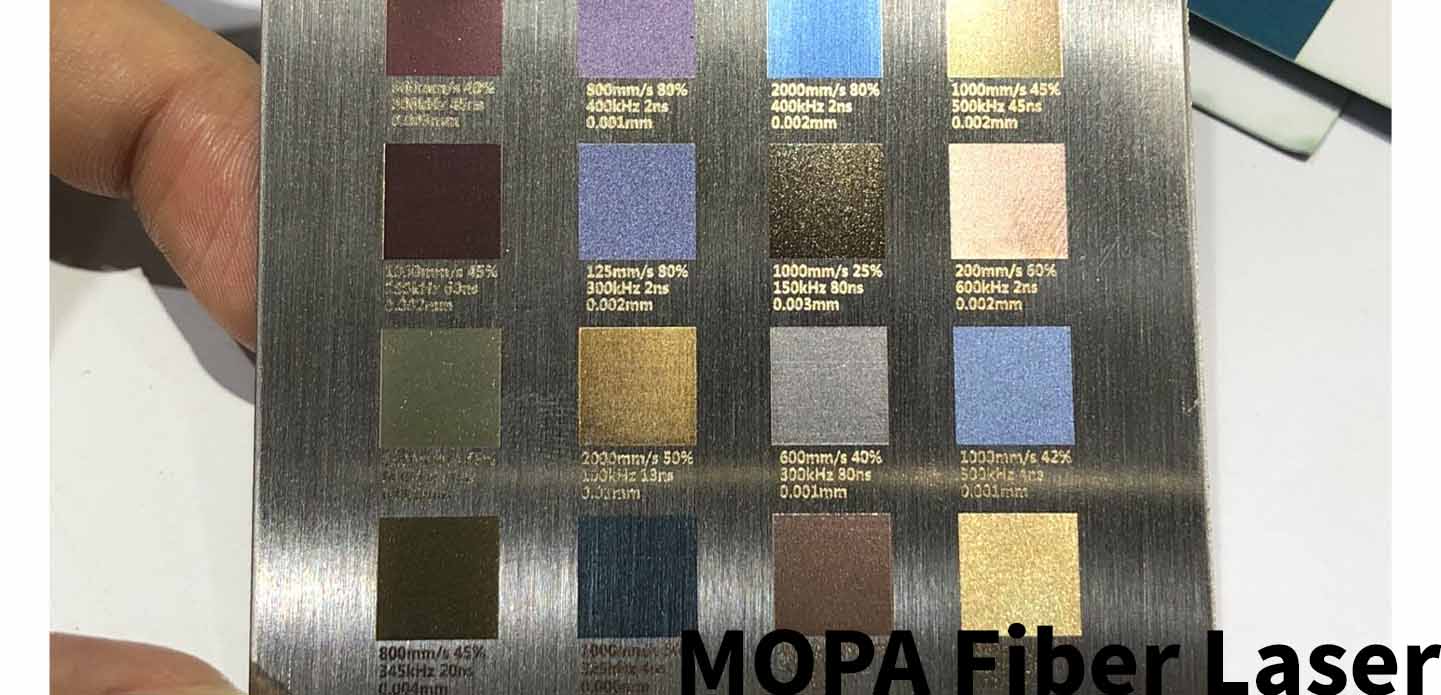

Color marking on stainless steel with multiple vivid shades

Micro-texturing and thin film removal without damaging the substrate

Deep engraving on metals with better edge control

Consistent marking on anodized aluminum, brass, copper and more

These capabilities make MOPA ideal for industries requiring strict marking quality, such as electronics (plastic chips, phone parts), medical devices (coating-sensitive tools), and luxury goods (logo engraving).

MOPA Fiber Laser vs. Q-Switched Laser

| Feature | MOPA Fiber Laser | Q-Switched Fiber Laser |

|---|---|---|

| Pulse width | Adjustable (2–500ns) | Fixed (typically ~100ns) |

| Material compatibility | Plastic, coated metal, stainless steel | Metal only (limited plastic use) |

| Color marking | Yes (on stainless steel) | No |

| Burn marks on plastic | None | Likely |

| Application flexibility | Higher | Lower |

In summary, if your project requires more than just metal engraving—such as marking colored logos, fine graphics, or delicate materials—the MOPA fiber laser is the superior option.

What’s the MOPA Fiber Laser Price?

The MOPA fiber laser price depends on various factors, including power (typically 20W, 30W, 50W, 60W, or 100W), laser source brand (e.g., JPT M7, M6+, MOPA MAX), system size, controller, lens configuration, and automation capability.

Price Reference Range (USD):

20W MOPA fiber laser marking machine: $2,800 – $4,000

30W MOPA: $3,500 – $5,000

60W–100W MOPA systems: $6,000 – $10,000+

Higher-end machines may include features like 3D galvo heads, rotary attachments, autofocus systems, and integrated smoke extractors. Always confirm with a trusted supplier based on your exact marking needs.

Applications of MOPA Fiber Laser Marking Machine

Electronics: No-damage plastic marking on connectors, switches, ICs

Medical industry: High-contrast, corrosion-resistant UDI codes

Aerospace: Lightweight component marking with no coating damage

Automotive: Serial number engraving, barcodes on precision parts

Consumer goods: Decorative patterns and branding marks

Its high stability, repeatability, and surface protection make MOPA lasers ideal for automated production environments.

Conclusion: Invest in Precision with a MOPA Fiber Laser

If you’re looking for a laser source that delivers flexibility, precision, and clean performance across metals and plastics, the MOPA fiber laser marking machine is the optimal choice. It offers better control, better results, and broader applications than conventional lasers—making it a valuable investment for businesses prioritizing quality, speed, and adaptability.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。