AOFEMTO Series Femtosecond Laser

| Model | Parameter Specification | Wavelength (nm) | Average Power (Watts) | Pulse Energy (µJ) | Specified Frequency (kHz) | Repetition Rate Range (kHz) | Beam Quality (M²) | Ambient Temperature (°C) | Power Supply Requirement (VDC/Watts) |

| AOFEMTO (UV Femtosecond) | 5W-100K | 355 | >5 | >50 | 100 | 50-300 | ≤1.2 | 15-35°C | 24/1000 |

| AOFEMTO (Green Femtosecond) | 10W-100K | 532 | >10 | >100 | 100 | 100K-1M | ≤1.2 | 15-35°C | 24/1000 |

| AOFEMTO (IR Femtosecond) | 20W-100K | 1064 | >20 | >200 | 100 | 10-1000 | <1.3 | 15-35°C | 24/1000 |

AOFEMTO Series femtosecond lasers offer compact design, high versatility, integrated analog power control, external trigger support, intelligent diagnostics, and excellent optical performance. Available in UV, Green, and Red wavelengths for precision industrial applications.

Product Pictures

Product Introduction

The AOFEMTO Series femtosecond laser line offers UV, Green, and Red wavelengths with a compact design and excellent versatility. Compared to previous generations, the footprint has been significantly reduced, while standardized dimensions across high-power picosecond and full-spectrum femtosecond lasers allow seamless replacement in existing systems.

AOFEMTO lasers provide rich functionality and ease of use, including integrated external analog voltage power control, external signal triggering, automatic crystal point switching, power and status monitoring, intelligent diagnostic recording, and pulse waveform editing.

Optical performance is outstanding, featuring excellent beam quality (M² < 1.1), customizable spot circularity (>95%), minimal astigmatism, precise focusing, and stable pulses. Ideal for precision micro-machining, industrial marking, and advanced packaging applications, the AOFEMTO Series combines compact size, versatility, and superior optical performance.

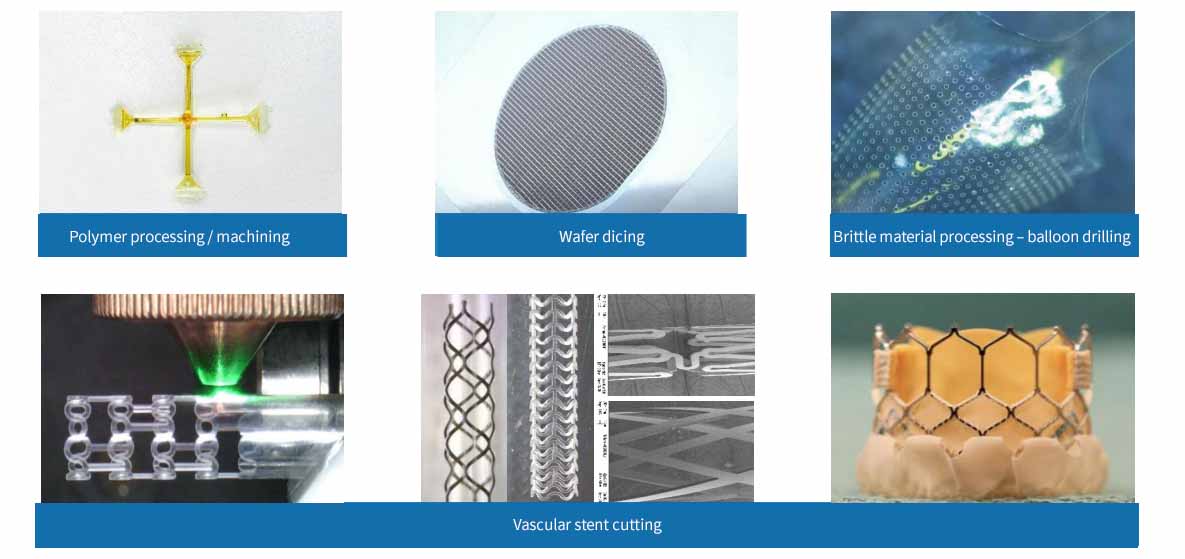

Application Cases

Femtosecond Laser Applications

Industrial Manufacturing & Precision Processing

Micro-structuring

Precision metal cutting

Thin film cutting and removal

Transparent material cutting (glass, sapphire, quartz)

3C electronics component processing (mobile phones, PCBs, FPCs)

Full-screen display glass cutting

Optical filter and component fabrication

Medical & Biological Applications

Medical device micro-machining

Precision surgical blade cutting

Tissue microdissection

Research & Advanced Optics

Photonics device fabrication

Optical microstructure fabrication

Surface functionalization

Material research and laboratory applications

Electronics & Consumer Products

OLED and LCD display cutting

Mobile phone antenna and antenna film cutting

Polyimide (PI) and P-layer film cutting

Electronic component marking

Specialized High-Difficulty Processing

Sapphire cutting

Complex-shaped glass cutting

Anti-corrosion and salt-spray marking