In today’s fast-evolving manufacturing landscape, fiber laser technology has quickly positioned itself as the global standard for precision marking, traceability, and industrial branding. Unlike traditional marking systems, fiber-based solutions deliver faster speed, deeper penetration, and exceptional long-term stability. These advantages are further amplified with the integration of single mode laser sources, which significantly enhance beam quality and reduce production errors. As portable marking becomes an essential need in various industries, innovations like the portable fiber laser marking machine are reshaping workflow efficiency and on-site operations. Meanwhile, understanding how different configurations affect the fiber laser machine price can help businesses identify the most cost-effective solution that meets their productivity goals.

1. The Rise of Fiber Laser Technology in Global Industries

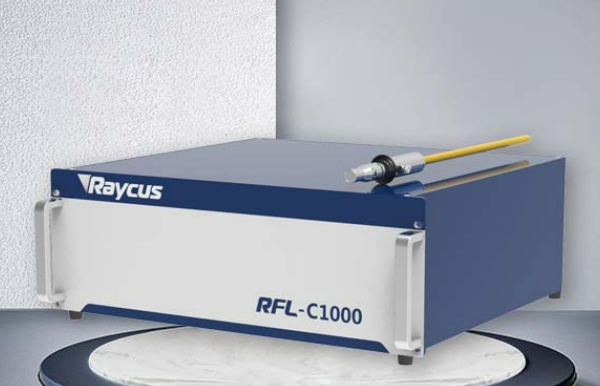

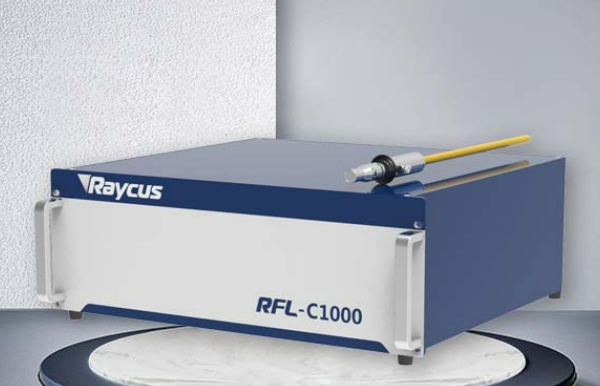

A modern fiber laser is designed for high-performance metal marking, thanks to its compact structure, long lifespan, and outstanding beam stability. Traditional CO₂ and inkjet systems often struggle with precision or long-term durability, especially on hard metals. This is where the single mode laser demonstrates its superiority—producing an extremely fine spot size ideal for micro-engraving and high-speed coding. The industrial shift toward traceability, serialization, and permanent marking has made tools like the portable fiber laser marking machine indispensable across automotive, aerospace, electronics, and medical manufacturing. With market demand rising, manufacturers now evaluate the fiber laser machine price based on productivity, software compatibility, and long-term ROI.

2. How Single Mode Laser Enhances Marking Accuracy

The most important characteristic of a fiber laser system is beam quality. A high-end single mode laser offers a perfect Gaussian beam (M²≈1.1–1.3), allowing extremely sharp, clean, and consistent marks. This precision is crucial for small components such as IC chips, medical needles, turbine blades, and jewelry. When combined with a portable fiber laser marking machine, this fine beam ensures stable performance even in outdoor or mobile applications. Because these advanced components greatly improve engraving quality, they are also key elements influencing the fiber laser machine price across different brands and product lines.

3. Portability & Productivity: The New Industrial Standard

Traditional workstation lasers require fixed setups and often involve moving heavy components for marking. Today, the portable fiber laser marking machine eliminates these limitations by bringing the power of a full-size fiber laser directly to the workpiece. This mobility is especially beneficial for:

Factory maintenance departments

Automotive repair and VIN marking

Metal fabrication shops

Construction and pipeline marking

On-site equipment branding

Thanks to its single mode laser source, the portable system ensures smooth and consistent marking regardless of location. Its compact structure, low power consumption, and plug-and-play design dramatically reduce setup time. Features like lighter weight, handheld scan head designs, and wireless control options can further influence the fiber laser machine price, depending on the chosen configuration.

4. Applications Across Metal, Plastics, Electronics & More

A modern fiber laser is capable of marking a wide variety of materials including stainless steel, aluminum, titanium, brass, ABS, PC, coated metals, and silicon wafers. The exceptional beam quality of a single mode laser makes it suitable for micro-precision tasks such as:

QR code and barcode engraving

Deep metal engraving

Serial number & batch coding

Logo marking

Anti-counterfeiting patterns

PCB chip coding

When mounted into a portable fiber laser marking machine, these capabilities extend to large machinery, outdoor installations, and heavy equipment that cannot be moved easily. This versatility is one of the major advantages that adds long-term value beyond the initial fiber laser machine price, especially for companies that handle high-mix, low-volume production.

5. Durability, Stability & Low Maintenance Costs

One of the biggest reasons fiber laser systems dominate the market is their exceptional reliability. Core benefits include:

100,000+ hours of maintenance-free operation

No consumables required

Air-cooled design with no complicated water cooling

Highly stable single mode laser energy output

Minimal downtime

When integrated into compact equipment like a portable fiber laser marking machine, these advantages help reduce operational costs and increase long-term profitability. Businesses comparing options often discover that although the initial fiber laser machine price may vary, the long-term TCO (Total Cost of Ownership) is significantly lower than CO₂ or UV lasers.

6. Factors That Influence Fiber Laser Machine Price

Although the fiber laser machine price can differ widely among manufacturers, the key price determinants include:

Laser Source (Brand & Type)

Premium sources such as IPG or MAX increase cost, especially for single mode laser configurations.

Power Output (20W–100W+)

Higher wattage improves speed and deep engraving capability, increasing the fiber laser value.

Portability & Design Features

A lightweight portable fiber laser marking machine with smart controls tends to cost more.

Software Compatibility

Better software (EzCAD3, JCZ board upgrades, automation support) can impact price.

Warranty & After-Sales Support

Longer warranties and global technical support raise the fiber laser machine price, but increase operational security.

7. Why Fiber Laser Offers the Best ROI for Modern Businesses

Companies worldwide prefer fiber laser systems because they provide unmatched cost performance. The high beam quality of a single mode laser allows ultra-clear marking, reduces scrap rates, and improves traceability—crucial for passing audits and improving customer trust. With a portable fiber laser marking machine, businesses can expand services, reduce downtime, and complete tasks faster. When evaluating the fiber laser machine price, most buyers recognize that fiber laser technology delivers superior long-term value, making it the most cost-effective choice for industrial marking.

8. How to Select the Right Fiber Laser for Your Needs

Before purchasing, consider these factors:

Required precision → choose single mode laser

Working environment → consider portable fiber laser marking machine

Expected workload → match marking speed with suitable fiber laser wattage

Budget planning → evaluate TCO, not just fiber laser machine price

Material types → ensure compatibility with metals & coatings

A well-matched system dramatically improves workflow efficiency and operational reliability.

Contact us today to get the highest-quality fiber laser solutions tailored to your business needs.