1. Background

In the mobile phone glass cover processing industry, traditional CNC mechanical machining has long been the dominant method. While this approach is mature, it faces multiple challenges that are increasingly difficult to overcome: cutting fluids cause environmental pollution, tools such as drill bits wear out quickly, machining efficiency is low, and the process requires significant equipment, manpower, and factory space — all of which lead to high production costs.

In recent years, with the growing demand for thinner and more precise glass components, laser cutting technology has become a preferred alternative, offering cleaner, faster, and more precise results for 0.25mm mobile phone glass cover production.

2. Customer Requirement

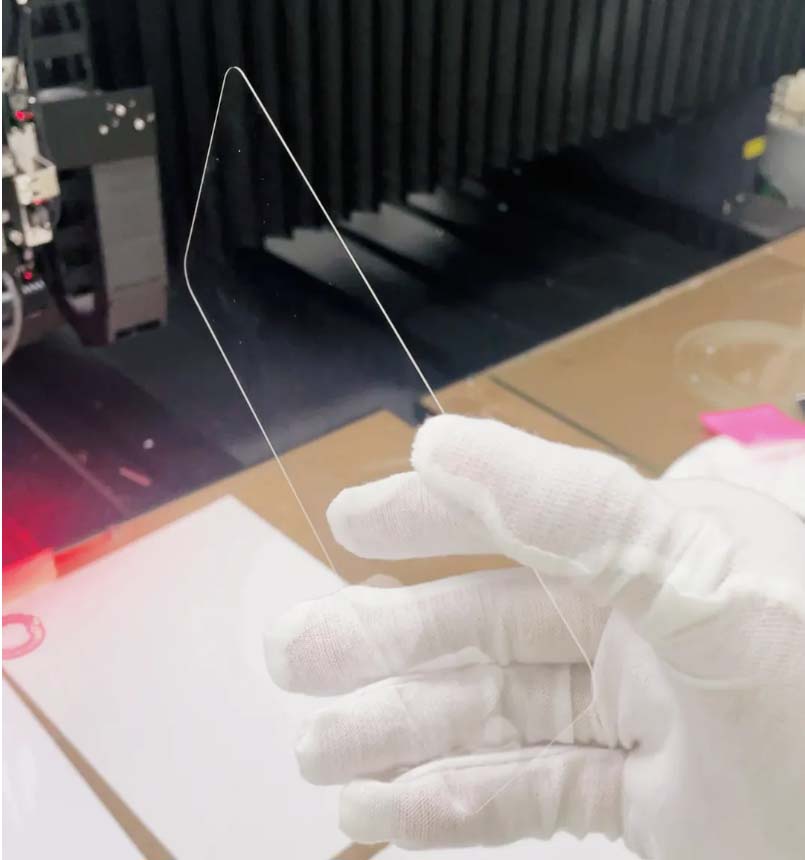

The customer required cutting 0.25mm thick mobile phone glass covers from original sheets into customized sizes, with strict quality demands: smooth edges, no chipping, consistent size and shape, and a yield rate above 99%. The process also needed to support batch processing with high stability and minimal maintenance.

3. Laser Cutting Solution

The ideal solution is a infrared picosecond laser glass cutting system, designed specifically for high-precision micro-processing of thin glass materials.

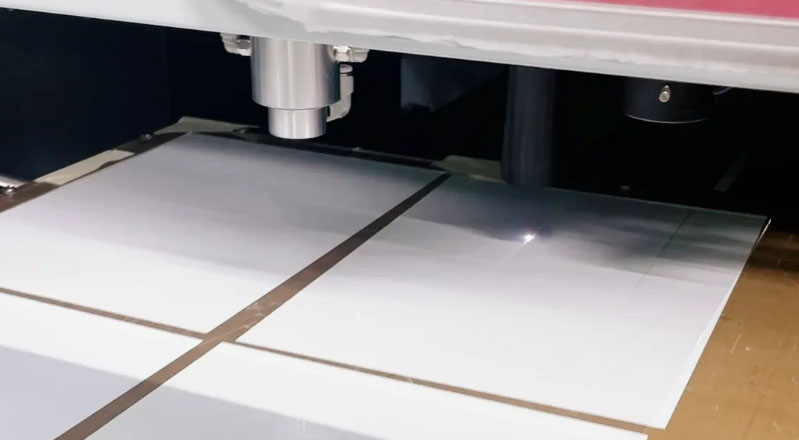

This system combines a high-frequency picosecond laser source, precision motion platform, and intelligent vision positioning system. It uses a non-contact cutting process, focusing high-energy laser beams onto precise cutting points to generate controlled micro-cracks within the glass, achieving a clean and precise separation without mechanical stress.

Key Advantages:

Non-contact processing: Eliminates mechanical stress and prevents secondary damage or deformation.

Ultra-fast laser pulse: The picosecond laser acts instantly, causing material vaporization or micro-explosion with minimal heat impact.

High precision: Cutting accuracy up to ±0.01mm, edge roughness < 5μm, and high perpendicularity.

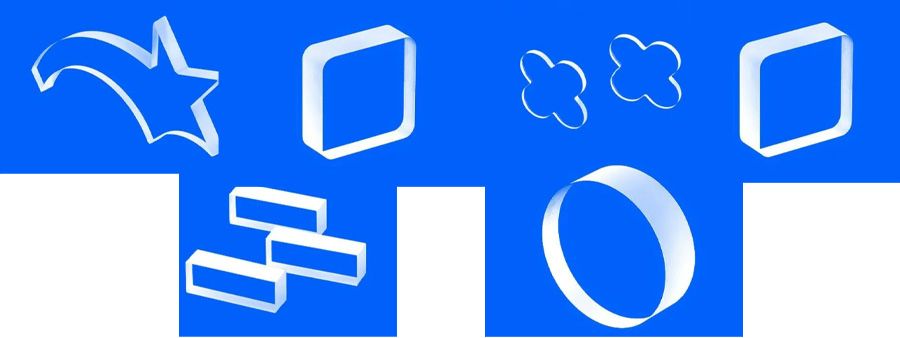

Flexible shape cutting: Supports circular, square, curved, and irregular outlines in a single process.

Batch production: With an automated platform, multiple pieces can be processed simultaneously, increasing efficiency up to 3 times.

No post-processing: Smooth, clean edges require no additional polishing or grinding.

This laser cutting approach significantly improves production efficiency, stability, and yield rate, making it a cost-effective and environmentally friendly alternative to CNC machining.

4. Cutting Results and Performance

Cutting Thickness: 0.25mm mobile phone glass cover

Cutting Accuracy: ±0.01mm

Edge Quality: Chipping ≤5μm, smooth and glossy surface

Efficiency: 3× faster processing speed, 99% yield rate in mass production

Supported Shapes: Round, square, irregular, curved, and special R-corner designs

The infrared picosecond laser cutting and scribing system integrates both cutting and cracking functions, often assisted by CO₂ laser for optimized separation. This ensures a seamless, high-speed, and dust-free manufacturing process.

5. Application Scope

Applicable Materials:

Ultra-clear glass

Standard white glass

Borosilicate glass

Quartz glass

Typical Products:

Mobile phone glass covers

Automotive glass panels

Camera lens covers

Sapphire covers and optical components

Filter and mirror substrates

6. Summary

Compared with traditional mechanical cutting, laser cutting for 0.25mm mobile phone glass covers offers unparalleled precision, efficiency, and stability. Its non-contact, ultra-fast, and high-yield nature ensures lower cost, minimal environmental impact, and consistent quality for high-end glass manufacturing applications.

If you are looking for a reliable laser glass cutting solution for thin and complex glass components, infrared picosecond laser systems provide a cutting-edge, high-efficiency option for modern electronics and optics production lines.