With the rapid advancements in laser technology, laser marking machines have made significant inroads across various industries. From logos and company names to barcodes, QR codes, batch numbers, and even patent information, laser marking has become indispensable in modern production lines. As demand for faster, more efficient production grows, online flying laser marking has emerged as an innovative solution for industries requiring high-speed, high-precision marking.

Flying laser marking, compared to static laser marking, offers several advantages that align with the needs of industries such as automotive, electronics, pharmaceuticals, and packaging, where speed and integration into existing production lines are essential. Let’s take a deeper dive into the key differences between these two technologies and explore why flying laser marking is gaining popularity in industrial automation.

What is Flying Laser Marking?

As the name suggests, flying laser marking refers to a form of laser marking used for products that are moving along a production line or conveyor belt. This technology allows for continuous, high-speed marking of products without interrupting the production flow. The products pass through the laser machine while the laser system is active, automatically marking them as they travel through the line. The advantage of this system is that it does not require manual handling, making it a fully automated process that increases efficiency and reduces labor costs.

In contrast, static laser marking is typically a semi-automated process where the product is manually loaded onto the machine, marked, and then removed. This method requires additional labor and is not as well-suited for high-speed, high-volume production environments. While both systems offer high-precision, durable marks, flying laser marking offers the added benefit of integration into industrial automation, which is crucial for industries demanding continuous and efficient production.

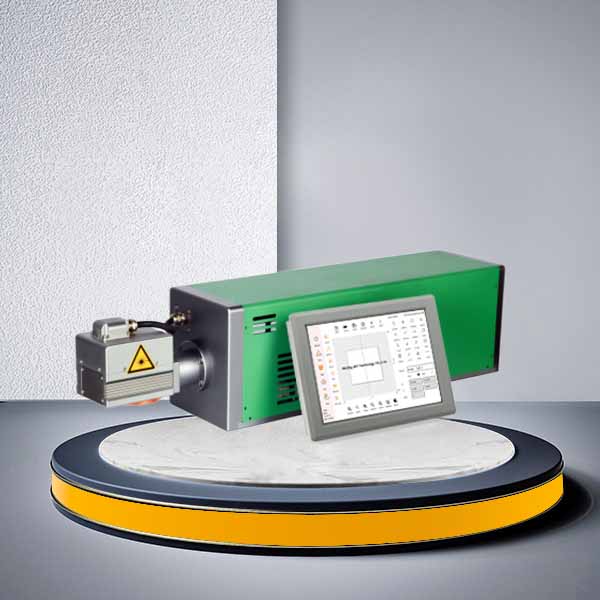

High-Speed Flying Laser Marking & Engraving Machine

Speed and Integration: Key Benefits of Flying Laser Marking

One of the standout features of the flying laser marking machine is its speed. With the ability to mark products at speeds of up to 189 meters per minute, this system is designed for high-throughput production lines. This makes it an ideal choice for industries where time and efficiency are critical, such as in the production of packaging materials, electronic components, and pharmaceutical goods.

Unlike static laser marking, which involves a stop-start process of loading and unloading, the flying laser marking system operates continuously without any interruption to the production line. It integrates seamlessly with conveyor systems and other automation equipment, ensuring that products are marked as they move through the manufacturing process. This not only boosts productivity but also minimizes the risk of human error and contamination, improving overall product quality.

Technical Differences: Hardware and Performance

The primary distinction between flying laser marking and static laser marking lies in their hardware and performance capabilities. Flying laser marking machines require high-performance components to achieve fast, precise marking while maintaining consistent quality. These machines rely on high-speed galvanometers, powerful lasers, and advanced control software to handle the continuous marking process.

In comparison, static laser marking systems typically have lower technical requirements. These machines can use standard galvanometers and lasers, as the process is slower and more controlled. However, when dealing with high-speed production environments, flying laser systems require superior hardware to keep up with the speed of the conveyor and achieve the necessary precision.

For flying laser marking systems, the speed of the galvanometer and the control software are critical factors that influence the performance of the machine. These components must work together to ensure accurate, high-speed marking. The galvanometer’s response time, marking speed, and the deflection angle of the laser all impact the efficiency and precision of the system.

Additionally, imported galvanometers from leading manufacturers like SCANLAB, Rui Lei, and SINO are often preferred for flying laser marking machines due to their superior performance in high-speed operations. These components are essential for achieving the high degree of automation and precision required in flying laser marking.

Cost and Automation: Reducing Labor and Increasing Efficiency

One of the major advantages of flying laser marking over static laser marking is its ability to automate the marking process entirely. Flying laser marking eliminates the need for manual handling, reducing labor costs and the potential for human error. It is particularly useful in industries where production speed and efficiency are paramount, such as in automotive, electronics, and food packaging.

With the ability to integrate seamlessly into industrial automation systems, flying laser marking machines help streamline the production process, reducing downtime and increasing throughput. This high level of automation also improves the overall consistency and quality of the marks, ensuring that each product is properly labeled with minimal oversight.

Applications in High-Speed Industries

Flying laser marking technology is increasingly being used in industries that require fast, efficient marking solutions. Here are some of the key applications:

Packaging: Online flying laser marking machines are widely used in the packaging industry to mark batch numbers, expiration dates, QR codes, and barcodes on a variety of materials, including plastic, cardboard, and glass. These systems can keep pace with high-speed packaging lines, ensuring that every product is properly marked without slowing down the process.

Electronics: In the electronics sector, flying laser marking is used to mark serial numbers, barcodes, and QR codes on PCBs, chips, and other electronic components. The ability to quickly mark small, delicate components without damaging them is a significant advantage.

Medical Devices: In the medical industry, flying laser marking is used to label surgical instruments, medical tubing, and other medical equipment with critical information, including serial numbers and sterilization dates. This ensures traceability and compliance with regulatory standards.

Automotive: Flying laser marking is also employed in the automotive industry to mark engine parts, chassis, and other components. The speed and precision of these systems make them ideal for high-volume automotive manufacturing environments.

Conclusion: Choosing the Right Solution for Your Business

Both flying laser marking and static laser marking have their merits, and the right choice depends on your specific production needs. Flying laser marking is the best option for businesses that require high-speed, high-volume production with minimal manual intervention. It offers the added benefits of industrial automation, cost efficiency, and integration into existing production lines.

On the other hand, static laser marking may be suitable for businesses that operate at a lower production rate or those that require more manual control over the marking process. However, for industries that demand continuous production with minimal downtime, flying laser marking is the superior choice.

As the demand for faster, more efficient production grows, flying laser marking will continue to be a game-changer in industries worldwide, driving greater automation and enabling businesses to meet the increasing demands of modern manufacturing.