What Is a UV Laser?

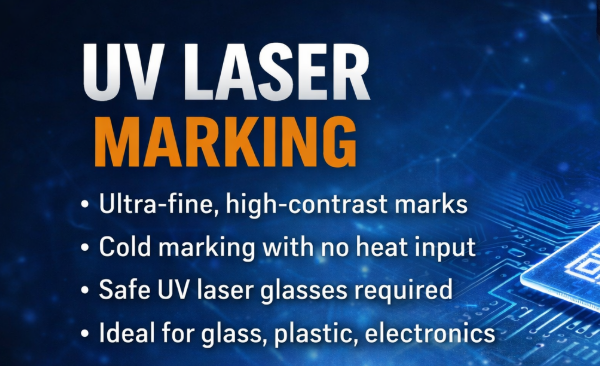

A UV laser (ultraviolet laser) operates at a short wavelength, typically 355 nm, which allows extremely fine spot sizes and minimal heat-affected zones. Compared with fiber and CO2 lasers, a UV laser enables cold processing, making it ideal for high-precision marking on sensitive materials.

Thanks to its superior beam quality and low thermal impact, the UV laser has become the preferred solution for applications that demand high contrast, fine details, and zero material deformation.

UV Marking: High Contrast Without Thermal Damage

UV marking uses ultraviolet laser energy to directly break molecular bonds on the material surface rather than relying on heat melting or burning. This process ensures clean edges, sharp text, and excellent readability.

Typical UV marking applications include:

Plastics (ABS, PP, PE, PVC)

Medical devices

Electronics and PCB boards

Glass and ceramics

Cosmetics and pharmaceutical packaging

UV marking is especially suitable for materials that are difficult to mark with traditional lasers, where surface damage or discoloration must be avoided.

UV Laser System: Core Components and Performance

A complete UV laser system consists of several key components designed for stable and precise operation:

UV laser source (355 nm)

High-speed galvanometer scanner

Precision laser control system

Industrial cooling and power management

Safety enclosure and protection design

An advanced UV laser system offers high positioning accuracy, stable output power, and long-term reliability, meeting the demands of continuous industrial production.

Why UV Laser Glasses Are Essential

Because ultraviolet laser radiation is invisible to the human eye, uv laser glasses are critical for operator safety. UV laser exposure can cause serious eye and skin damage if proper protection is not used.

High-quality UV laser glasses provide:

Certified UV wavelength protection (355 nm)

High optical density (OD)

Comfortable and ergonomic design

Compliance with international laser safety standards

Any professional UV laser system must be operated with appropriate uv laser glasses to ensure a safe working environment.

Advantages of UV Laser Technology

Compared with other laser marking technologies, UV laser systems offer significant advantages:

Ultra-fine marking resolution

Cold marking with minimal heat input

High contrast and permanent marks

No damage to sensitive substrates

Suitable for micro and precision marking

These advantages make the UV laser an ideal choice for high-end manufacturing industries.

How to Choose the Right UV Laser System

When selecting a UV laser system, consider:

Material type and marking requirements

Required marking speed and precision

Production volume and automation needs

Safety standards and protective accessories such as uv laser glasses

Choosing the right configuration ensures optimal performance and long-term cost efficiency.

Professional UV Laser Solutions for Your Business

We provide advanced uv laser and uv laser system solutions tailored for industrial UV marking applications. Our systems deliver stable performance, precise control, and reliable safety design to meet the highest production standards.

Whether you need a compact UV marking machine or an integrated UV laser system for automated production lines, we offer customized solutions and technical support.

Contact us today for a free consultation, sample testing, and professional UV marking solutions.