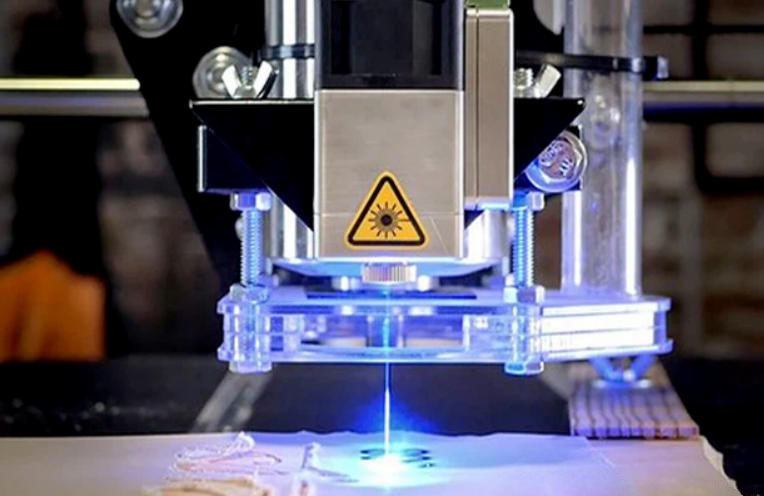

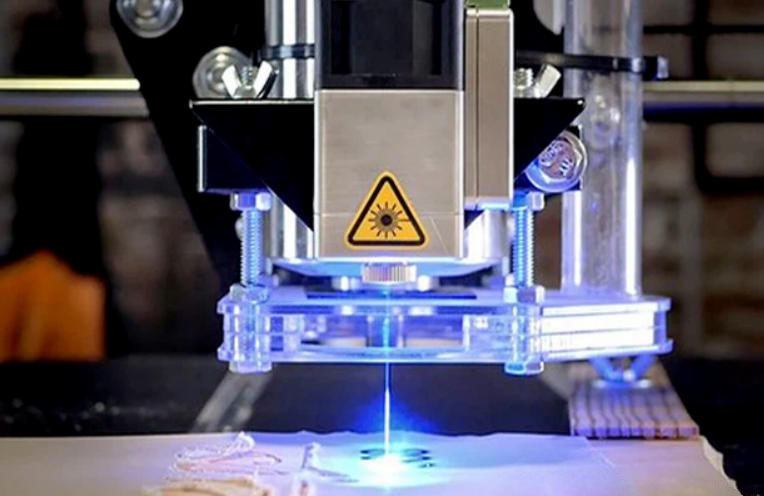

With the development of laser technology, the use of lasers to modify and engineer the surface of materials has become increasingly sophisticated. Traditional surface treatment of metal materials has a long history, but it is often complicated, messy, and difficult to control with high precision. In contrast, laser processing enables rapid and localized heating of workpieces, allowing precise heating or cooling under atmospheric or vacuum environments. By adjusting laser parameters, various surface treatment effects can be achieved on different materials. Laser processing is non-contact and produces very little deformation on the workpiece.

According to the purpose of surface treatment, laser surface technologies can be classified into:

Laser surface modification (including glazing, remelting, alloying, and cladding)

Laser texturing

Laser removal processes (such as laser cleaning)

Laser Surface Treatment

Laser Marking and Laser Surface Texturing

01

1. Laser Marking Technology

Laser marking is one of the most widely used applications of laser processing today. Modern laser marking systems can be used on almost any material. Most laser marking machines use near-infrared pulsed lasers to create visible marks on surfaces. The marking depth and patterns can be precisely controlled by software.

Different materials require different pulse durations, frequencies, and temperature levels—for example, marking on metals, glass, or optical fibers all follow specific parameter standards.

2. Laser Surface Texturing (Laser Roughening / Peening)

Continuous-wave lasers are not ideal for controlled surface texturing, but dense pulsed marking achieves excellent results. Depending on the application, millisecond, picosecond, or femtosecond pulses can be selected to achieve optimal surface effects.

A notable example is texturing the surface of cold-rolled steel or patterned rollers. Rollers used in the metal rolling process must have uniform surface roughness and long service life. Laser pulsed texturing has become the most efficient method.

During processing, thousands of laser pulses per second are focused on the roller surface, forming small molten pools. Gas blowing around the molten pool helps push the molten material outward, forming small arc-shaped protrusions and micro-pits. These microstructures significantly strengthen and harden the roller surface.

This technique greatly improves the efficiency and quality of cold-rolled sheet production.

Cold-rolled steel sheets and strips are widely used in automotive manufacturing, construction, electronics, household appliances, and defense industries. For example, automotive body panels must have evenly distributed “micro-pits” to enhance paint adhesion, which is achieved through specialized rolling and surface processing techniques.

Laser Surface Modification

02

1. Laser Surface Hardening (Phase Transformation Hardening)

This is essentially a laser-induced “quenching” process. Unlike traditional methods that struggle to achieve localized hardening, lasers can easily heat specific surface regions. After the laser rapidly melts the surface layer, it cools and self-quenches immediately once the beam leaves.

This creates a thin transformed microstructure layer with refined crystals that dramatically increase surface hardness.

2. Laser Surface Alloying

Laser alloying heats a local area of the material surface or forms a thin molten layer, then diffuses or adds alloying elements to change the surface chemical composition. This improves mechanical, physical, and chemical properties.

Its advantages include:

Localized treatment

Minimal substrate distortion

No damage to base material properties

High efficiency and rapid heating

It is ideal for enhancing critical areas of components such as die edges, camshafts, and valve lifters.

Laser alloying extends component lifespan while reducing processing steps and alloy material consumption.

3. Laser Cladding

Laser cladding is similar to alloying, but with better control over the composition and thickness of the surface layer. Additional alloy material is fused onto the surface using laser energy.

The cladded layer forms a strong metallurgical bond with the substrate while maintaining its own original alloy composition with minimal dilution.

This allows engineers to create a surface layer vastly different from the substrate—ideal for wear resistance, corrosion resistance, or high-temperature performance.

4. Laser Cleaning

Laser cleaning uses high-energy laser pulses to instantly remove contaminants, rust, coatings, or oxides from surfaces. It is a solvent-free, environmentally friendly, and highly selective cleaning process. Laser cleaning can remove micro-scale particles that conventional methods fail to address.

Common laser cleaning methods include:

Dry laser cleaning – direct laser ablation of contaminants

Laser + liquid film – a liquid layer is applied and then vaporized by laser

Laser + inert gas – air blow assists in removing debris and prevents oxidation

Laser loosening + chemical – loosen with laser, followed by gentle chemical removal

It offers high flexibility, precision, and remote operation capabilities, making it ideal for inaccessible or hazardous environments.

Optimized Conclusion

Laser surface treatment has evolved into a highly advanced and versatile technology widely used across automotive manufacturing, aerospace, molds, electronics, construction, and other industries. By precisely controlling heat input, melting depth, energy density, and pulse characteristics, laser technologies provide unmatched surface modification capabilities—achieving hardness improvement, enhanced adhesion, corrosion resistance, surface texturing, and ultra-clean processing.

With the continuous improvement of laser sources, optics, and control systems, laser surface treatment will continue to replace traditional processes, offering cleaner, more efficient, and higher-precision solutions for modern manufacturing.