Do you often face situations like these:

A batch of high-value automotive components needs coating removal, an important mold requires rust cleaning, or oil contamination on precision parts is affecting downstream processes…

Don’t worry — we’ve got you covered.

Instead of drowning in complex parameters, let’s start from real applications.

Follow these three steps to help you find the laser cleaning machine that is truly “meant for you.”

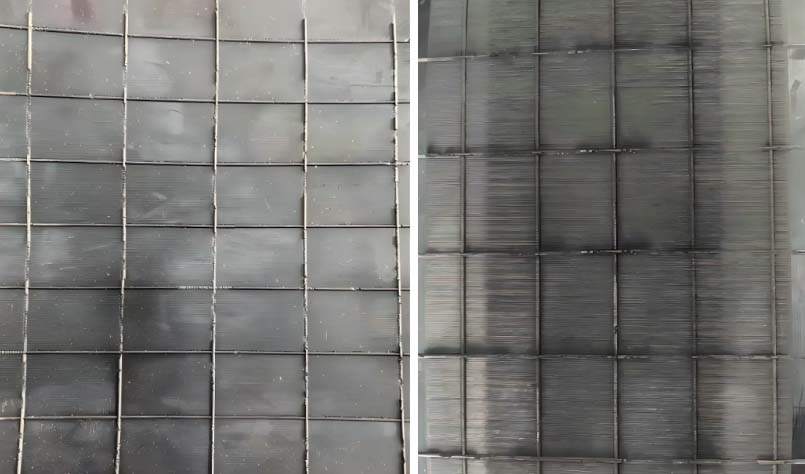

Before & After Cleaning of Motor Stator

Step 1: Identify your cleaning object and cleaning requirements

Cleaning Object

Material: Is it carbon steel, aluminum alloy, stainless steel, or more delicate materials like copper or titanium alloy?

Shape: Flat surface, curved surface, or a complex structure with threads or blind holes?

Value: Is it a standard component or a high-value core part?

This directly affects the cost of a failed cleaning attempt.

Cleaning Requirements

What to remove: Rust, oil, oxide layer, paint, or plating layer?

Cleanliness level: “Visually clean” or must meet a specific Sa standard?

Base material protection: Can the substrate tolerate slight damage, or must the process achieve zero damage?

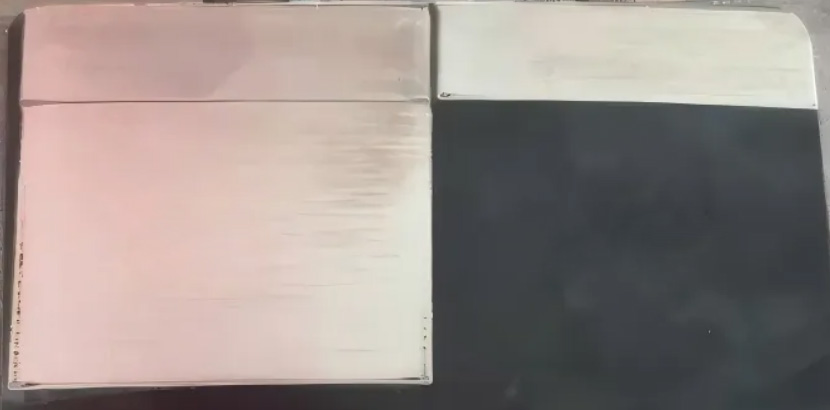

Coating Removal Example

Step 2: Assess “whether it cleans well” and “whether it’s easy to use”

Core Performance — The balance of “Speed” and “Precision”

Precision (“Accurate”):

Can the machine achieve selective cleaning?

Is it capable of precisely covering welds, blind holes, and complex surfaces?

Does the control system ensure removal of contaminants without harming the base material?

This is the foundation of achieving truly zero-damage cleaning.Efficiency (“Fast”):

How efficient is the cleaning while maintaining precision?

This determines your production cycle and throughput.

User Experience — The reflection of “Simple” and “Stable”

Ease of operation:

Does it require complicated adjustments or long setup time by professional engineers?

A great system should include a rich process parameter library, allowing operators to achieve optimal results with one click.Stability:

Can the machine work continuously for 8 hours without failure?

What is the lifespan of its core laser source?

These factors directly influence long-term cost and productivity.

Total Cost — The hidden truth behind “visible” and “invisible” costs

Visible cost:

The upfront price of the machine.Invisible cost: The real game changer:

Consumables:

Does it require chemical agents or abrasives?

Laser cleaning has the advantage of almost zero consumables — only electricity.Environmental cost:

Does the process generate wastewater or waste residues that require handling?

Laser cleaning is eco-friendly and can save substantial environmental processing fees.Labor cost:

Is the system simple enough for general operators, without needing expensive skilled technicians?

Epoxy Resin Cleaning on Magnetic Core

Step 3: Verify whether the machine performs as promised

Sample Cleaning Test

Words mean nothing — results speak for themselves.

Send your real workpiece to the manufacturer and request a cleaning test.

Seeing the cleaning effect, time cost, and operation process firsthand is the most solid proof.

After-sales Support

Does the manufacturer provide 24/7 technical support?

Can their technicians arrive on-site within 48 hours?

Fast service response minimizes your downtime and losses.

Successful Case Studies

An experienced partner can foresee potential problems and offer proven solutions.

For example, a manufacturer with successful cases in automotive parts, molds, and rail transit applications is undoubtedly more trustworthy.

Tire Inner Wall Roughening Process

Choose Wisely

Choosing a laser cleaning machine is not just about picking a piece of equipment —

It is choosing a production method that is more efficient, lower cost, and environmentally friendly,

as well as choosing a partner you can trust in the long run.

We provide pulse and continuous laser cleaning systems covering multiple power ranges and applications, with hundreds of successful cases in automotive components, molds, rail transit, and more.

Specifications are cold numbers, but real results speak the truth.

We are not just a supplier — we are a partner who helps you solve real-world problems.

Now, we invite you to complete the “third step”:

Send us your cleaning sample, and we will provide a free cleaning test.

Let the results speak for themselves and help you make the best decision!