What is a Fiber Laser?

A fiber laser is a type of solid-state laser that uses an optical fiber as the gain medium. Compared with traditional laser sources such as CO2 or YAG, fiber lasers offer higher efficiency, better beam quality, and longer service life. This makes them the preferred choice for precision marking, engraving, cutting, and welding in modern manufacturing industries.

Advantages of Fiber Laser Technology

Fiber laser technology brings several outstanding advantages that make fiber laser engravers and fiber laser marking machines highly competitive in the global market:

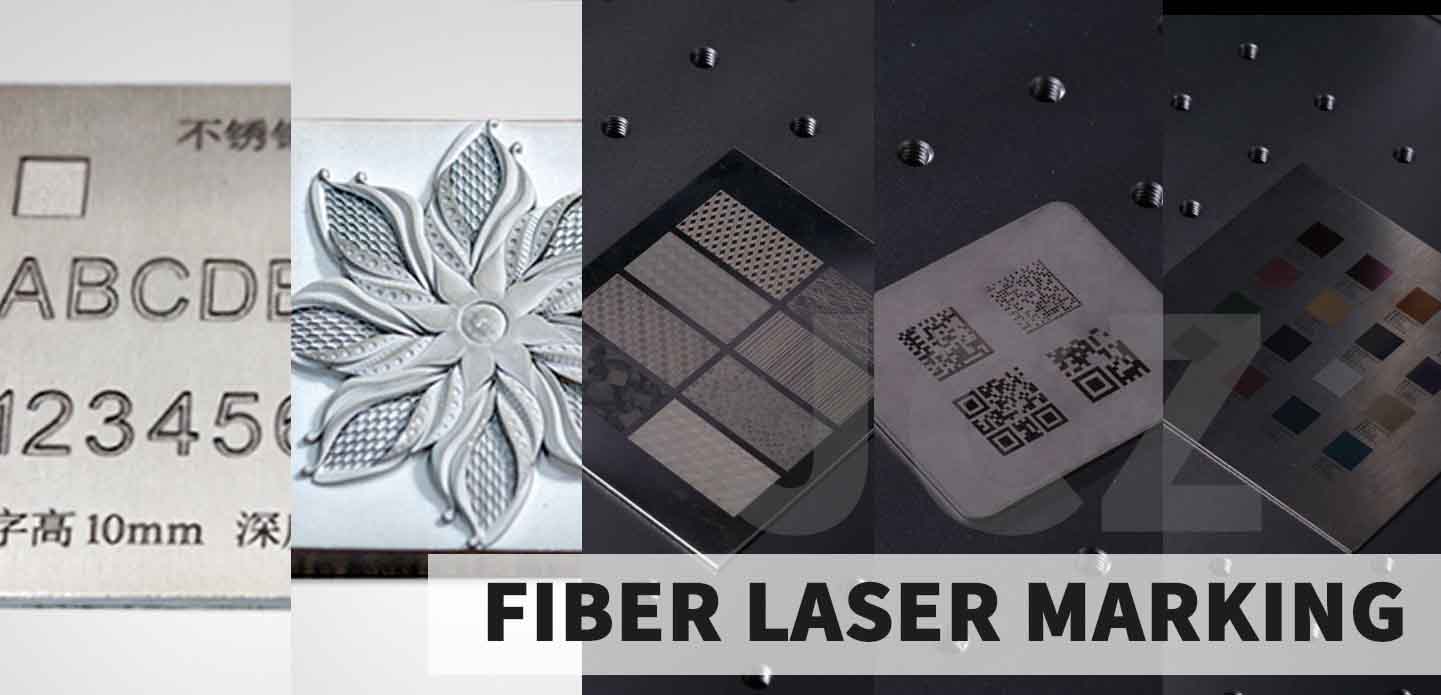

High Precision: With excellent beam quality, fiber lasers can achieve ultra-fine marking and engraving, suitable for detailed logos, serial numbers, and micro-text.

Long Lifespan: The laser source typically lasts over 100,000 working hours, reducing maintenance costs and downtime.

High Efficiency: Fiber lasers offer higher photoelectric conversion efficiency (up to 30%), saving energy and reducing operational costs.

Low Maintenance: Unlike CO2 or lamp-pumped YAG lasers, fiber lasers require minimal maintenance, providing stable and reliable operation.

Flexibility: Compact design and easy integration into automated production lines.

Applications of Fiber Laser Engravers

Fiber laser engravers are widely used in industrial and commercial fields because of their versatility and precision. They can engrave or mark on various materials such as:

Metals: Stainless steel, aluminum, copper, brass, gold, silver, and titanium.

Plastics: ABS, polycarbonate, polyethylene, and other engineering plastics.

Special Materials: Ceramics, coated metals, anodized aluminum.

These capabilities make fiber lasers ideal for permanent marking, traceability, and product branding.

Fiber Laser Marking Machine in Different Industries

The fiber laser marking machine has become an essential tool across many industries:

Electronics Industry: PCB marking, chip codes, and connectors.

Automotive Industry: Part identification, VIN marking, and component traceability.

Medical Devices: Surgical instruments, implants, and tools require permanent, sterile markings.

Jewelry & Luxury Goods: Fine engraving on gold, silver, and other precious metals.

Industrial Manufacturing: Tools, bearings, and machinery parts.

With its wide range of applications, the fiber laser marking machine helps manufacturers improve efficiency, enhance product quality, and meet international traceability standards.

Why Choose Fiber Laser Engravers?

Choosing fiber laser engravers means investing in a solution that delivers precision, durability, and cost-effectiveness. Whether for high-volume production or detailed custom engraving, fiber lasers offer unmatched performance. They are also eco-friendly, producing no consumables and minimal waste compared to traditional marking technologies.

Conclusion

The rise of fiber laser technology has transformed the global laser marking and engraving industry. With superior beam quality, high efficiency, and broad material compatibility, fiber laser engravers and fiber laser marking machines provide long-term value and reliability. For manufacturers seeking advanced marking solutions, fiber lasers are the ultimate choice.