What Is Fly Laser Marking?

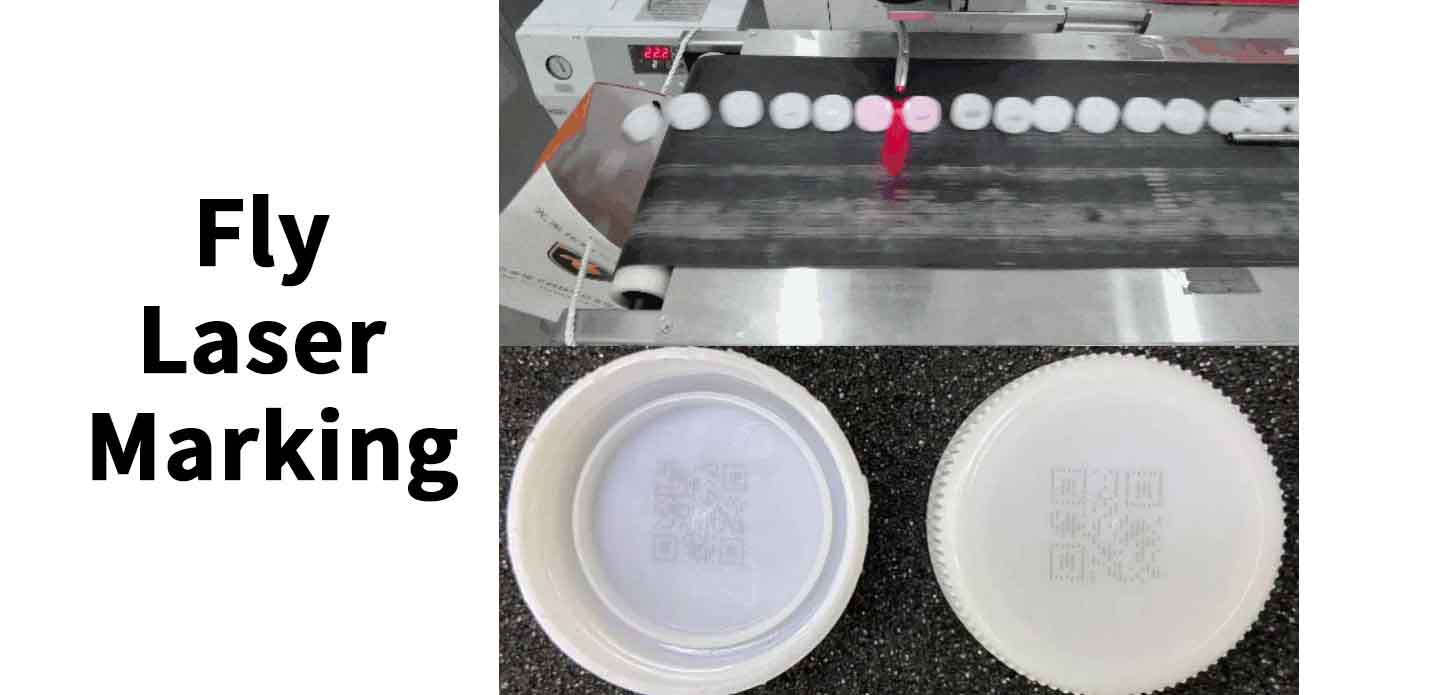

Fly laser marking (also known as flying laser marking) is a dynamic marking process that enables high-speed engraving or coding on products while they are moving on a production line. Unlike traditional static marking, fly laser systems synchronize with conveyor speeds to deliver real-time, non-stop coding, improving efficiency and reducing downtime.

This advanced technique is widely used in packaging, electronics, medical devices, automotive parts, and cable manufacturing—anywhere where traceability, branding, or compliance information must be added without interrupting production.

How Does a Fly Laser Marking Machine Work?

A fly laser marking machine consists of:

High-speed laser source (Fiber, CO₂, or UV based on material)

Encoder and sensor for speed detection

Galvo scan head for precise beam control

Control software that dynamically adjusts marking in real time

As the product moves on the conveyor belt, the system detects its speed and position, and then marks the surface on-the-fly — maintaining perfect clarity and accuracy even at high speeds.

Key Advantages of Fly Laser Marking

Using fly laser marking in production environments offers numerous benefits:

| Advantage | Description |

|---|---|

| Non-stop Marking | No need to pause the conveyor; boosts throughput |

| Clean & Permanent | High-contrast, wear-resistant, and eco-friendly marks |

| Time-Saving | Perfect for 24/7 production and high-speed lines |

| Low Maintenance | No inks or solvents; minimal operational costs |

| Wide Material Compatibility | Works on metal, plastic, rubber, cardboard, glass, etc. |

Whether you’re marking expiry dates, QR codes, barcodes, serial numbers, or batch numbers, fly laser marking ensures flawless results — at full line speed.

Typical Applications

Fly laser marking systems are ideal for:

Pharmaceutical & medical packaging (compliance and traceability)

Food & beverage (expiration and batch coding)

Wire & cable marking (length measurement and coding)

Automotive components (VIN codes, serial numbers)

Electronics & PCBs (QR codes, data matrix, logos)

Why Choose Our Fly Laser Marking System?

Our advanced online fly laser marking systems support:

Conveyor speed up to 150 m/min

Encoder & photocell integration

Multi-line text, logos, 2D codes, and serial numbers

Support for Fiber Laser (metal), CO₂ (non-metal), and UV Laser (plastic, glass)

Easy integration into MES/ERP for smart factories

Whether you’re running a fully automated factory or upgrading from inkjet coding, our systems provide cleaner, smarter, and more reliable marking.

Ready to Upgrade Your Line with Fly Laser Marking?

Discover how fly laser marking technology can streamline your production, improve marking quality, and reduce operating costs.

Contact us now for a free consultation, technical specifications, or a live demo.

由用户投稿整理稿件发布,不代表本站观点及观点,进行交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。