In industrial production, have you ever faced these frustrations — slow marking speeds that delay the entire production line? Blurry marks that make product traceability difficult? Or machines that simply “refuse to work” when switching materials?

In today’s precision-driven and efficiency-focused manufacturing world, a reliable laser marking machine that solves these problems is key to staying competitive. Let’s take a look at why this high-performance laser marking solution has become a must-have for modern factories.

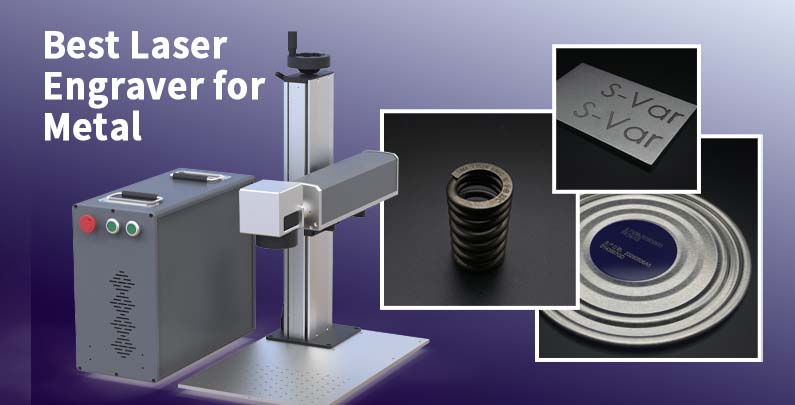

01 — Product Overview

This laser marking machine is engineered specifically for industrial marking applications. Built on years of experience and advanced laser technology, it combines a high-quality fiber Q-switched laser source with an independently developed marking control system.

From design to performance, every detail focuses on three essential principles: precision, efficiency, and stability — helping companies reduce marking costs, boost productivity, and upgrade overall product quality.

02 — Key Features

1. High Precision Marking — Perfect Down to the Smallest Detail

With a 1064 nm wavelength fiber laser, excellent beam quality (M² ≤ 1.7), and a repetition frequency of 25–100 kHz, this system achieves 0.1 mm ultra-fine marking. Whether it’s complex vector graphics, small alphanumeric characters, or high-contrast bitmap images, every mark is sharp and clean — ideal for industries requiring precision such as electronics and medical devices.

2. High Speed and Efficiency — Visible Productivity Gains

Compared with conventional marking systems, this laser marking machine improves marking speed by over 30%, allowing more parts to be processed per shift.

Its non-contact design eliminates downtime for consumable replacement, and with one-click parameter recall when switching materials, it minimizes idle time — making it perfect for mass production and multi-material workflows.

3. Wide Material Compatibility — One Machine for All Tasks

Whether marking metals like stainless steel, aluminum, and copper, or plastics like PVC and hard polymers, this system ensures stable and consistent performance. Businesses no longer need to purchase multiple machines for different materials, significantly lowering equipment investment costs.

4. Reliable and Durable — Lower Long-Term Maintenance Costs

The core laser source has a lifetime exceeding 100,000 hours, and all critical components are rigorously tested to handle 24/7 industrial operation.

Its integrated design minimizes potential failure points and simplifies daily maintenance — reducing downtime and saving on repair costs over time.

5. Easy Operation — Even Beginners Can Master It Quickly

The system supports both touchscreen and mouse-keyboard operation, paired with intuitive marking software. It’s compatible with popular design tools such as EzCad and CorelDraw, allowing easy graphic import and simple parameter adjustment.

New operators can typically learn to use it independently within one hour of training.

03 — Application Fields

Thanks to its strong performance and versatility, this laser marking solution is widely used in multiple industries, including:

Electronics: Marking model numbers, serial codes, and traceability data on chips, PCBs, and electronic parts.

Automotive: Engraving identification and traceability codes on engine components, wheels, and wiring systems.

Medical Devices: High-precision marking for batch numbers, expiration dates, and identification data on instruments and consumables.

Hardware Tools: Engraving brand logos, specifications, and parameters to improve product recognition.

Art & Crafts: Creating personalized designs, text, and patterns for custom-made products.

Marking Results

If your factory is looking for a no-consumable, low-power, maintenance-free laser marking solution, this equipment is worth exploring.

It’s more than just a machine — it’s a reliable partner that enhances productivity and strengthens your competitive edge.