Laser marking and laser engraving are two of the most common laser applications in modern manufacturing and customization. Although the terms are often used interchangeably, they differ significantly in process principles, processing depth, and application scenarios. Let’s take a closer look at these two techniques.

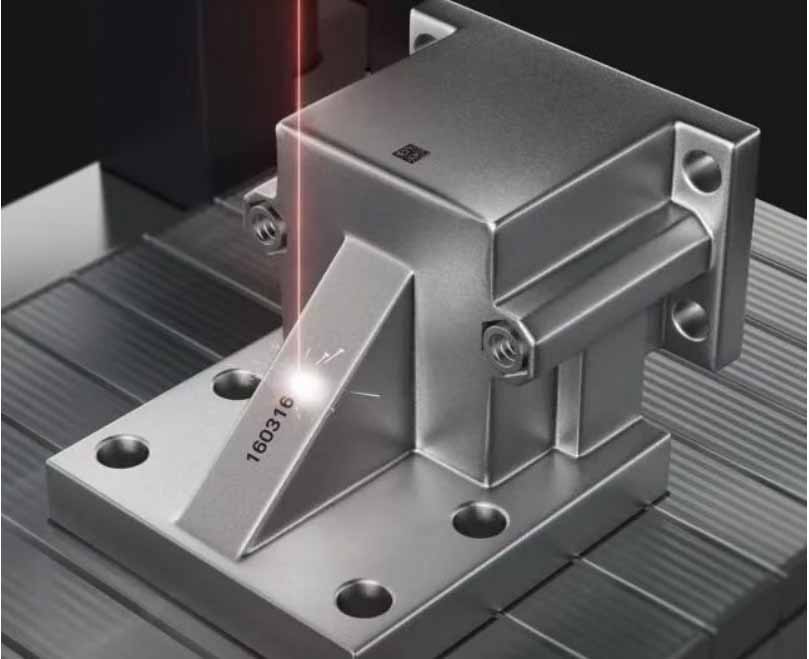

What is Laser Marking?

Laser marking uses a high-energy laser beam to irradiate the surface of a material, causing physical or chemical changes that leave a permanent mark. Common methods include surface discoloration, localized melting, or ablation. Laser marking can be applied to a wide range of materials such as metal, plastic, glass, and ceramics to quickly produce logos, serial numbers, barcodes, or QR codes.

Advantages:

- High precision, ideal for very small characters and fine patterns.

- Multiple marking effects (discoloration, removal, foaming, etc.).

- Fast processing speed with low noise.

- No consumables, resulting in low maintenance costs.

- Well-suited for industrial traceability, ensuring compliance and reliability in production.

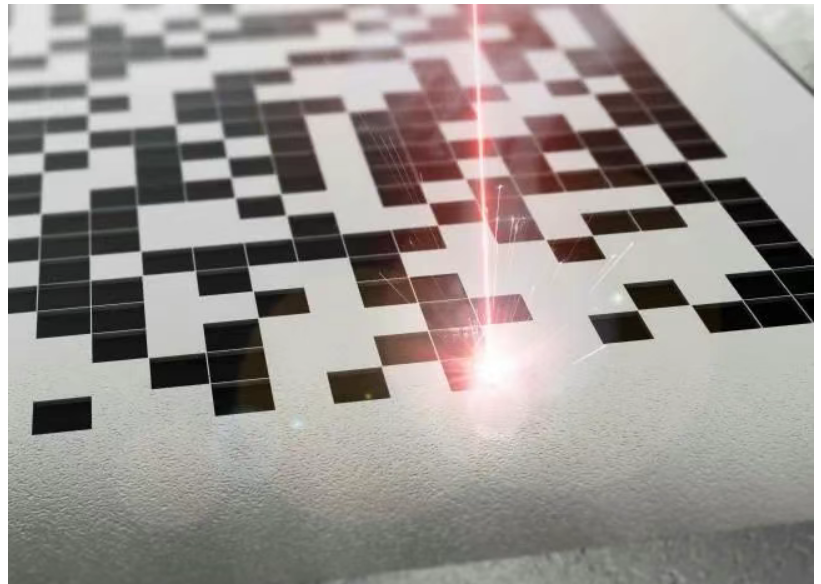

What is Laser Engraving?

Laser engraving uses a high-powered laser beam to directly vaporize the surface material, removing part of the upper layer to create visible grooves or patterns that can also be felt to the touch. Compared with laser marking, engraving produces greater depth and a more durable, three-dimensional effect.

Laser engraving typically supports two modes:

- Raster Engraving: Based on pixels arranged in rows and columns, similar to printing an image.

- Vector Engraving: Based on geometric paths and points. Images can be resized without loss of quality.

Advantages:

- Fine and detailed lines and shapes.

- Long-lasting and wear-resistant results.

- Compatible with many materials (metal, wood, plastic, glass, etc.).

- Highly automated, no extra tools or inks required.

- Ideal for crafts, personalized products, and signage.

Application Comparison

- Laser Marking: Best suited for industrial traceability, part serial numbers, QR codes, and logos. It emphasizes functionality and information delivery.

- Laser Engraving: Best suited for personalization, such as jewelry, trophies, awards, decorative items, and corporate signage. It emphasizes artistry and durability.

Conclusion

The main difference between laser marking and laser engraving lies in processing depth and application:

- Marking creates a surface-level mark, focusing on identification and traceability.

- Engraving removes deeper layers of material, focusing on customization and decorative effects.

Together, these techniques complement each other and play an important role in both industrial manufacturing and personalized design.

Contact us to get the latest laser marking and laser engraving solutions.