In industrial manufacturing, surface cleaning may seem simple, but it is a crucial step that directly affects product quality and production efficiency. Traditional cleaning methods—such as chemical soaking and sandblasting—not only pose environmental risks but may also cause irreversible damage to precision components. With breakthroughs in laser technology, pulse laser cleaning companies are revolutionizing industrial cleaning through highly efficient, environmentally friendly, and precise solutions. This article takes you inside this emerging sector to explore its technical principles, application scenarios, and development prospects.

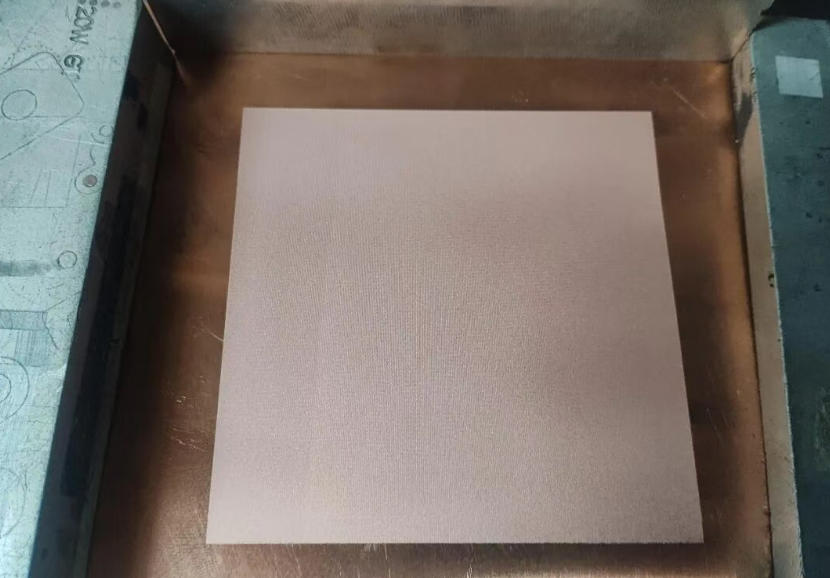

Pulse Laser Cleaning Equipment in Operation

1. Pulse Laser Cleaning: Technical Principles & Core Advantages

Pulse laser cleaning uses high-energy, short-pulse laser beams to irradiate the surface of a workpiece, instantly vaporizing or detaching contaminants to achieve non-contact cleaning. The core mechanism involves three steps: laser energy absorption, thermal expansion of contaminants, and separation from the substrate.

Compared with traditional methods, this technology offers three major advantages:

1. Breakthrough in Environmental Protection

No chemicals are required throughout the process—only electricity—eliminating wastewater and exhaust emissions entirely. According to field data from certain enterprises, a single device can reduce chemical solvent consumption by more than 10 tons per year, equivalent to cutting 30 tons of CO₂ emissions.

2. Revolution in Precision Control

The laser beam can be focused to a micrometer-level diameter, and with intelligent control systems, enables differentiated cleaning for various materials and contamination levels. For instance, in semiconductor manufacturing, it can selectively remove photoresist residues without damaging the wafer surface.

3. Major Efficiency Improvement

A single pulse can clean an area in the square-centimeter range, and when integrated into automated production lines, the cleaning speed increases 5–10 times. An automotive parts manufacturer reported a 30% increase in production capacity and a 45% reduction in labor costs after adopting the technology.

Effect Comparison: Laser Cleaning vs. Traditional Cleaning

2. Application Scenarios: From Precision Manufacturing to Cultural Heritage Protection

Pulse laser cleaning technology is far more adaptable than traditional methods, and its applications span multiple industries:

1. Aerospace

Engine blade repair is a typical application. Traditional sandblasting may alter the stress distribution on metal surfaces, while laser cleaning can accurately remove oxide layers without affecting the substrate. Data shows that blade fatigue life increased by more than 20% after laser treatment.

2. New Energy

In lithium battery manufacturing, substrate cleanliness before electrode coating directly affects battery performance. Laser cleaning achieves nano-level cleanliness, reducing internal resistance by 15% and extending cycle life by 30%. Leading battery manufacturers have fully replaced conventional cleaning processes with laser technology.

3. Cultural Heritage Conservation

The gentle nature of laser cleaning shines in artifact restoration. When removing corrosion from bronzeware, experts adjust pulse parameters to preserve historical textures on the surface, achieving a perfect balance between cleaning and protection.

4. Microelectronics

In 5G communication equipment production, laser cleaning removes flux residue from PCBs after soldering, preventing short circuits. One telecom company reported an increase in product yield from 92% to 99.5%, saving millions annually in rework costs.

3. Technology Evolution: From Single Cleaning to Intelligent Integration

Pulse laser cleaning enterprises are advancing innovation in three major directions:

1. Multi-wavelength Composite Technology

By integrating multiple laser wavelengths, machines can handle different types of contaminants. One enterprise developed a composite laser cleaning system capable of removing metal oxides, paint, and oil simultaneously, increasing equipment utilization by 60%.

2. Intelligent Vision Guidance

With AI image recognition, the device automatically identifies contaminated areas and optimizes cleaning paths. An automotive welding line reported that the pass rate increased from 85% to 99.2%, while manual intervention dropped by 90%.

3. Portable Design

For on-site maintenance, companies have developed handheld laser cleaning equipment weighing only 3.5 kg with a power density of 200 W/cm². In nuclear power plant maintenance, the device cleans radioactive contaminants through a 10 mm protective layer, improving efficiency eightfold over conventional methods.

Application of Handheld Laser Cleaning Devices

4. Industry Challenges & Pathways to Breakthrough

Despite promising growth, laser cleaning enterprises still face three major challenges:

1. High Initial Investment

Equipment cost remains a barrier for small and medium-sized businesses. Some companies have introduced a “rental + service sharing” model that reduces customers’ upfront investment by 60%, promoting market adoption.

2. Talent Shortage

The industry requires professionals well-versed in both laser physics and manufacturing processes. To address this, companies are collaborating with universities to establish specialized laboratories, expanding technical teams threefold in three years.

3. Lack of Standardized Systems

Unified quality standards are still lacking in the industry. Leading enterprises are working with associations to draft the Pulse Laser Cleaning Process Specification, which will regulate market practices and facilitate healthy industry growth.

5. Outlook: A Key Enabler of Green Manufacturing

Driven by global carbon-reduction initiatives, pulse laser cleaning is becoming a core technology for the green transformation of manufacturing. Market research forecasts that the global laser cleaning market will exceed USD 5 billion by 2028, with a compound annual growth rate of 22%. As a major global manufacturing hub, China is taking the lead through technological innovation and model upgrades.

From precision chips to large-scale equipment, from cultural relics to advanced manufacturing, pulse laser cleaning enterprises are redefining industrial cleanliness with light. This silent revolution is not only about efficiency—it represents humanity’s pursuit of sustainable development. Each sweep of a laser beam reveals not just the disappearance of contaminants, but the rise of a cleaner, more efficient future for manufacturing.