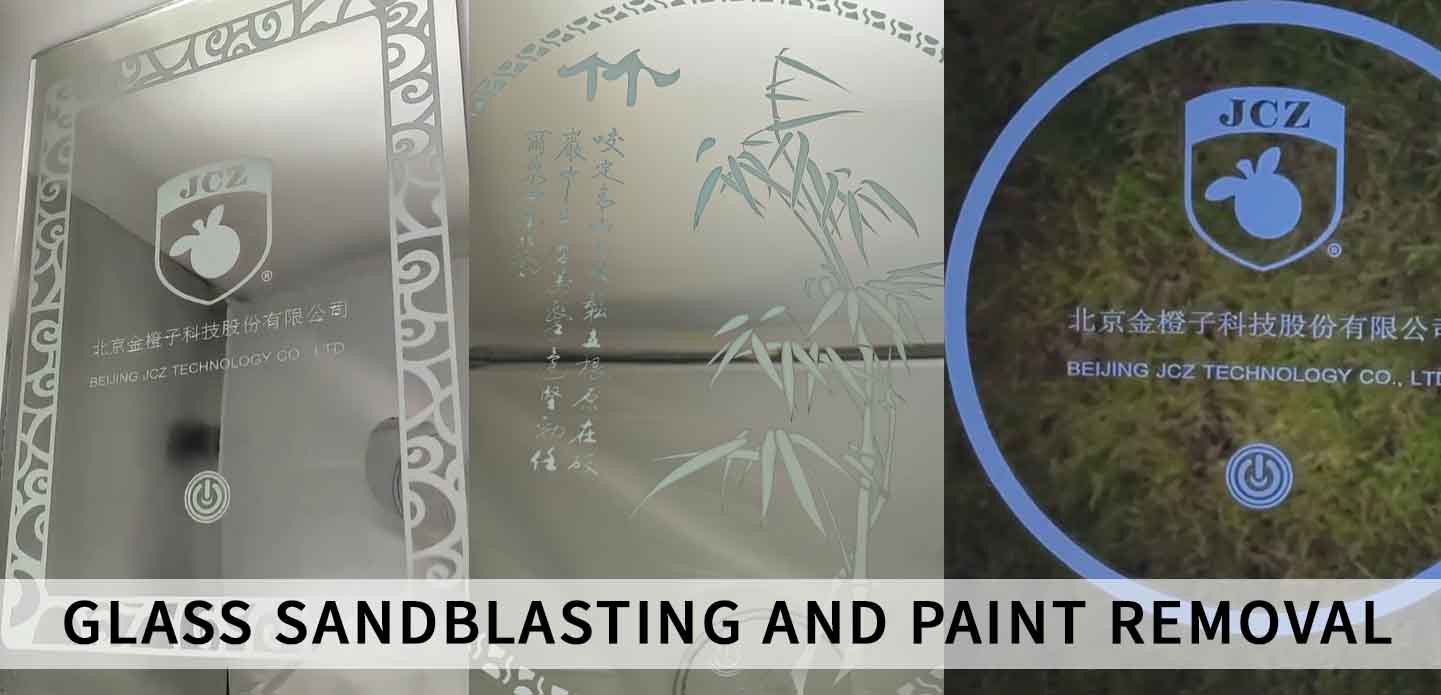

Large Format Intelligent Control System for Glass Sandblasting and Paint Removal

In the modern manufacturing industry, a laser marking machine is more than just a tool for engraving logos or serial numbers—it has evolved into a versatile solution capable of precise surface processing, complex pattern creation, and efficient material removal. Among the advanced systems available today, the large format intelligent control system stands out, especially in applications like glass sandblasting and paint removal.

Precision in Glass Sandblasting

Traditional glass sandblasting relies on manual or stencil-based methods, which can be time-consuming and less consistent. With the integration of a large format intelligent control system, laser marking machines can guide the sandblasting process with computer-controlled precision. This allows manufacturers to achieve uniform textures, intricate decorative patterns, or frosted finishes on glass panels—whether for architectural glass, furniture, or artistic installations—without compromising quality.

The intelligent control system ensures every movement of the sandblasting nozzle is coordinated in real time, avoiding overlaps, uneven finishes, and wasted material. The result is a higher-quality surface, reduced production time, and minimized labor costs.

ZEUS | LARGE SIZE INTELLIGENT-CONTINUOUS LASER PROCESSING SOFTWARE

Efficient Paint Removal without Damage

Removing paint from delicate or high-value surfaces can be challenging. Mechanical scraping or chemical stripping often risks damaging the substrate or causing environmental hazards. A laser marking machine equipped with a large format intelligent control system enables non-contact paint removal, using controlled laser energy to vaporize or separate the paint layer without affecting the underlying material.

This method is especially valuable in industries like automotive restoration, aerospace maintenance, and architectural refurbishment, where both precision and surface integrity are essential. The automated system ensures consistent paint removal across large areas while reducing operator fatigue.

Benefits of a Large Format Intelligent Control System

High Accuracy – Computer-guided motion ensures repeatable, precise results.

Large Work Area – Suitable for oversized glass panels, vehicle parts, or industrial components.

Customizable Programs – Operators can set parameters for different materials and processing needs.

Reduced Waste – Optimized path planning minimizes unnecessary movements and resource usage.

Versatility – Supports multiple functions beyond marking, including engraving, cleaning, and coating removal.

Conclusion

A laser marking machine equipped with a large format intelligent control system is far more than a marking tool—it is a multi-functional surface processing powerhouse. From glass sandblasting to paint removal, it offers unparalleled precision, efficiency, and versatility, helping industries achieve superior results with less waste and lower costs.