A laser cleaner metal system is an advanced cleaning solution that removes rust, paint, oil, and contaminants from metal surfaces using high-energy laser beams. Unlike traditional sandblasting or chemical cleaning, a laser cleaner metal machine offers precise, eco-friendly, and contactless cleaning. Industries such as automotive, aerospace, shipbuilding, and manufacturing rely on this technology to restore metal surfaces without causing wear or secondary waste.

What is a Rust Remover Machine?

A rust remover machine is designed to eliminate corrosion and oxide layers from metals, ensuring longer lifespan and improved surface quality. Modern rust remover machines often use fiber laser technology, which delivers controlled energy pulses to vaporize rust. Compared to mechanical grinding or chemical treatment, a rust remover machine is safer, more efficient, and requires little to no consumables. It’s widely applied in factories, workshops, and maintenance industries.

What is a Fiber Laser Cleaning Machine?

A fiber laser cleaning machine is a specialized system that uses fiber laser beams for industrial cleaning applications. Known for high efficiency, low maintenance, and long service life, a fiber laser cleaning machine provides precise surface preparation and coating removal. From cleaning welding seams to restoring cultural heritage artifacts, the versatility of a fiber laser cleaning machine makes it one of the most popular choices in industrial cleaning today.

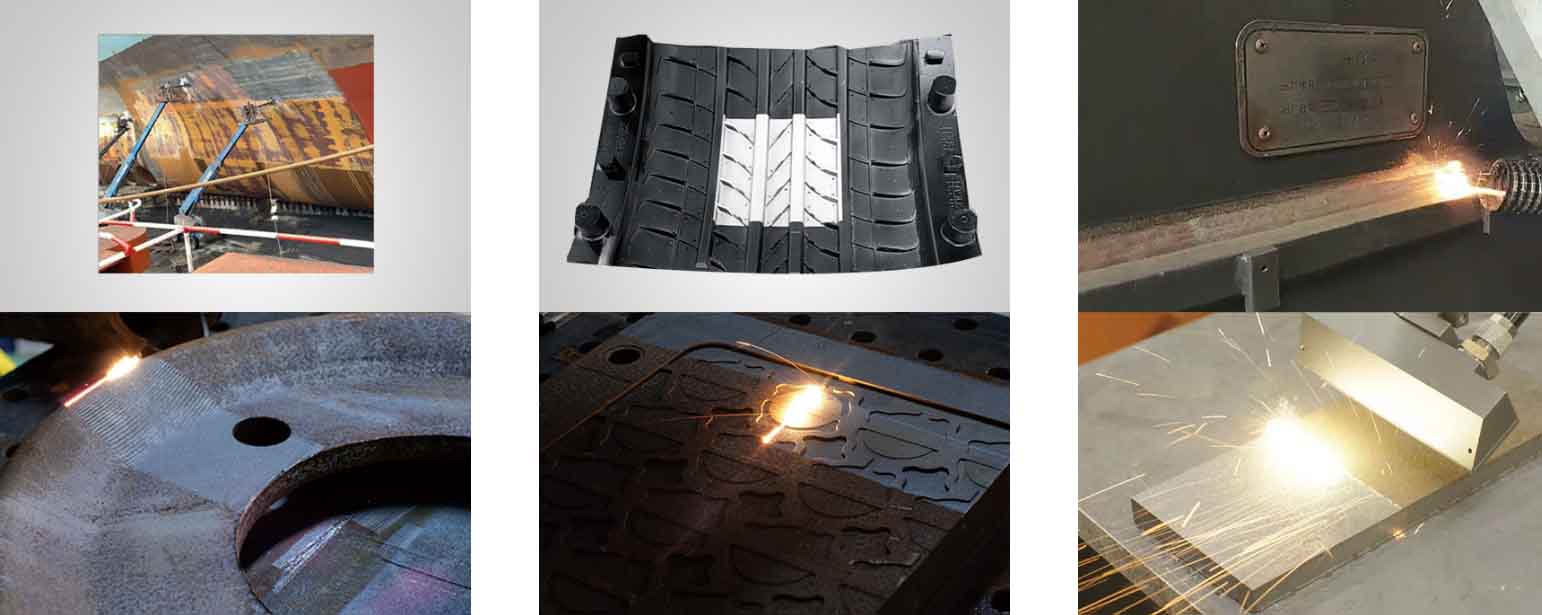

Applications of Laser Cleaner Metal, Rust Remover Machine, and Fiber Laser Cleaning Machine

Automotive Industry – A laser cleaner metal can remove rust and paint layers from car bodies, frames, and spare parts.

Shipbuilding – Heavy corrosion on ships can be treated efficiently with a rust remover machine, improving safety and performance.

Manufacturing Industry – A fiber laser cleaning machine ensures high-quality metal preparation before welding, coating, or painting.

Cultural Heritage – Delicate surfaces like statues or historical artifacts can be safely restored using a laser cleaner metal with low-power settings.

Benefits of Using Fiber Laser Cleaning Technology

Non-contact & Precise – A fiber laser cleaning machine removes contaminants without damaging the base metal.

Eco-Friendly – No chemicals are required, making a rust remover machine safe for workers and the environment.

Cost-Effective – Minimal maintenance and zero consumables lower operating costs.

Versatile – A laser cleaner metal works on steel, aluminum, copper, titanium, and more.

How to Choose the Right Laser Cleaner?

When selecting a laser cleaner metal, rust remover machine, or fiber laser cleaning machine, consider:

Power Range – Low-power for delicate cleaning, high-power for industrial rust removal.

Portability – A handheld laser rust remover offers flexibility for on-site jobs.

Automation – Integrated laser rust removal systems can be connected to robotic arms for mass production.

Budget & Applications – Choose based on your business needs, whether small workshop use or industrial-scale cleaning.

Conclusion

Investing in a laser cleaner metal, a reliable rust remover machine, or an advanced fiber laser cleaning machine helps businesses achieve cleaner, safer, and more durable results. With applications across industries, this technology not only improves efficiency but also reduces environmental impact and long-term costs.

Contact us today to learn more about our fiber laser cleaning machines and request a free quotation for your business needs.