An ultrafast laser is a type of laser that emits extremely short pulses of light—measured in femtoseconds (10⁻¹⁵ seconds) or picoseconds (10⁻¹² seconds). These incredibly brief bursts deliver extremely high peak power without damaging surrounding material, making ultrafast laser technology essential in applications that require extreme precision and minimal thermal effects.

Unlike continuous wave lasers, an ultrafast laser system releases its energy in rapid, short pulses, enabling micrometer-level accuracy in industrial manufacturing, scientific research, and medical procedures.

How Ultrafast Laser Technology Works

An ultrafast laser machine generates pulses through a process called mode-locking, where multiple wavelengths of light are synchronized to form ultra-short bursts. This allows for:

High Peak Power – The concentrated energy in each pulse can remove or modify material instantly.

Cold Processing – Minimal heat transfer means reduced thermal damage, even on delicate materials.

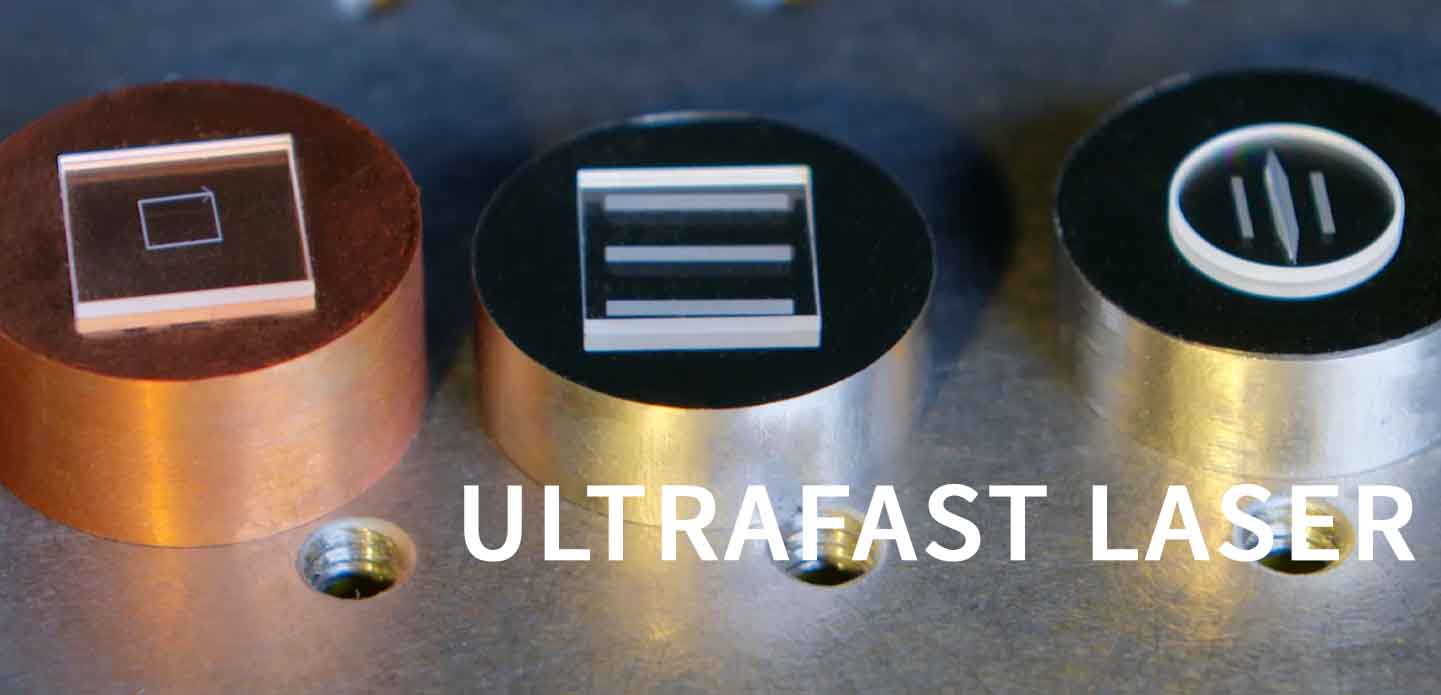

High Precision – Ideal for micro-patterning, drilling, and surface structuring at the nanometer scale.

Applications of Ultrafast Lasers

The versatility of ultrafast laser technology makes it a preferred tool in many industries:

Electronics Manufacturing – Micro-drilling circuit boards, processing semiconductor wafers.

Medical Devices – Cutting stents, corneal surgery, and biomedical imaging.

Industrial Processing – Ultrafast laser cutting, engraving, and micromachining of metals, ceramics, and polymers.

Scientific Research – Time-resolved spectroscopy, nonlinear optics experiments.

Benefits of Using an Ultrafast Laser System

Non-thermal Processing – Perfect for heat-sensitive materials.

Exceptional Precision – Micrometer-scale accuracy for advanced manufacturing.

Versatile Material Capability – Works on metals, glass, polymers, and biological tissues.

Minimal Post-Processing – Clean cuts and smooth finishes reduce the need for additional work.

Choosing the Right Ultrafast Laser Machine

When investing in an ultrafast laser machine, consider factors such as:

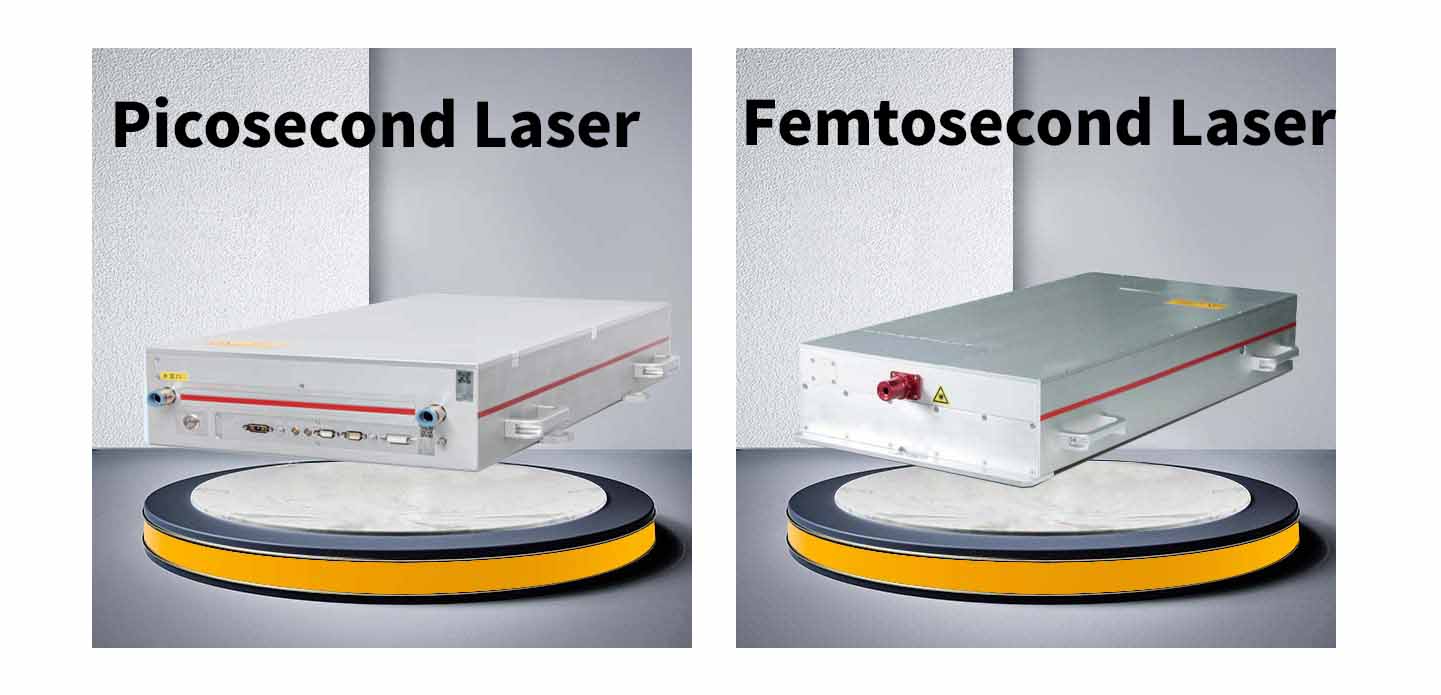

Pulse Duration – Femtosecond or picosecond, depending on your precision requirements.

Power Output – Higher wattage for thicker or harder materials.

Repetition Rate – Determines processing speed.

Integration Options – Whether you need a standalone machine or an integrated production line system.

Conclusion

An ultrafast laser is a groundbreaking technology that delivers unmatched precision and efficiency in material processing. From ultrafast laser micromachining to delicate medical procedures, its ability to cut, engrave, and modify materials with minimal heat impact makes it an invaluable tool in modern industry.

If you’re looking for a reliable, high-performance ultrafast laser system, choosing the right specifications for your application will ensure you get the best results and a long-lasting return on investment.