Introduction

In the competitive global market, precision and efficiency are the keys to success. One of the most revolutionary tools in modern manufacturing is the fiber optic laser. With the rise of fiber laser engravers and advanced laser marking fiber technologies, companies in industries like electronics, automotive, aerospace, and medical devices are embracing these solutions to achieve higher productivity, lower costs, and unmatched precision.

What is a Fiber Optic Laser?

A fiber optic laser is a type of solid-state laser where the active medium is an optical fiber doped with rare-earth elements. Unlike traditional CO₂ or YAG lasers, the fiber design allows for a more compact structure, greater stability, and extremely high beam quality. This makes it the ideal choice for laser marking fiber applications where detailed engraving and permanent marking are required.

Advantages of Fiber Laser Engravers

High Precision & Quality

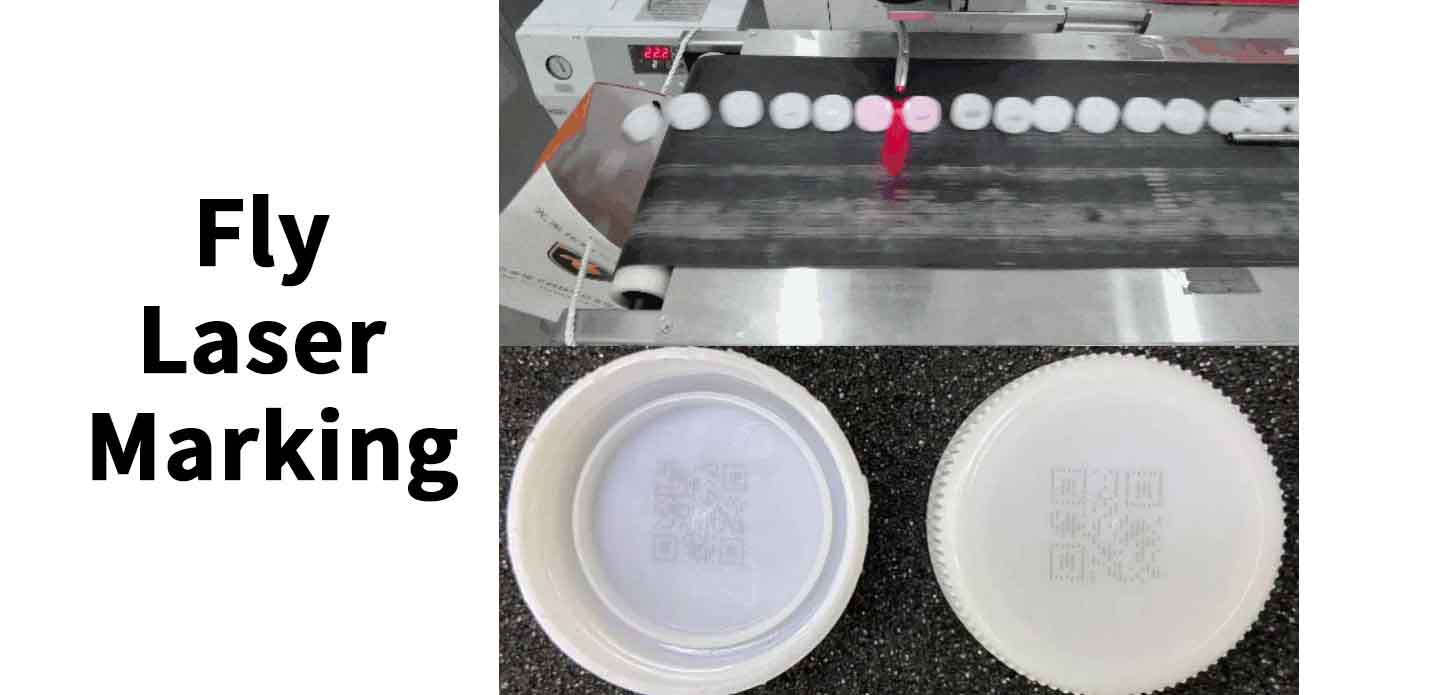

Fiber laser engravers produce extremely fine and clear marks on metal, plastics, and even challenging surfaces. Whether it is logos, barcodes, QR codes, or product serial numbers, the results are permanent, tamper-proof, and resistant to wear.Versatility Across Materials

From stainless steel, aluminum, and titanium to plastics and ceramics, fiber optic laser systems can process a wide variety of materials. This makes them indispensable for industries requiring laser marking fiber solutions for diverse applications.Speed & Efficiency

A key advantage of fiber laser engravers is their fast processing speed. The high energy density and superior beam delivery mean shorter cycle times and higher throughput, which directly reduce production costs.Low Maintenance & Long Lifespan

Unlike traditional laser systems, fiber optic laser machines require minimal maintenance. With no need for mirrors or alignment, they offer a lifespan of up to 100,000 hours, making them a reliable investment for long-term production.Environmentally Friendly

Laser marking fiber technology eliminates the need for inks, solvents, or consumables, making it a clean and eco-friendly solution. Companies adopting this technology not only improve efficiency but also meet sustainability goals.

Applications in Different Industries

Electronics: PCB marking, semiconductor engraving, and micro components.

Automotive: VIN codes, parts identification, and component traceability.

Medical: Surgical instruments, implants, and UDI markings.

Aerospace: Durable component marking under extreme conditions.

Why Choose Fiber Laser Engravers for Your Business?

Choosing a fiber optic laser solution means choosing speed, durability, and flexibility. The ability to permanently engrave high-contrast marks ensures compliance with global traceability standards. With the growing demand for precision, laser marking fiber systems are no longer an option but a necessity for companies that aim to compete globally.

Conclusion

The advantages of fiber optic laser technology and fiber laser engravers are clear: precision, speed, durability, and cost-effectiveness. As industries move toward smarter manufacturing, investing in advanced laser marking fiber solutions will help businesses not only improve efficiency but also win the trust of high-value clients.