When it comes to precision engraving on fragile materials like glass, many businesses wonder: “What tool is used to engrave glass?” The most advanced and reliable answer is the UV glass laser marking machine. With its ultra-fine laser beam and non-contact process, UV technology has become the preferred solution for industries that require high accuracy, permanent results, and delicate surface treatment.

Why UV Laser is the Best Choice for Glass Engraving

Glass is a highly brittle material, which makes traditional engraving methods such as mechanical tools or sandblasting risky and inefficient. The UV glass laser marking machine stands out because of its ability to engrave without applying physical pressure or generating excessive heat.

Cold Processing Technology – UV lasers operate at a short wavelength (355 nm), producing a “cold” laser effect. This ensures no cracks, burns, or thermal damage on the glass surface.

High Precision – The ultra-fine spot size makes it possible to engrave micro text, QR codes, barcodes, and intricate designs with extreme clarity.

Permanent Results – The markings are resistant to fading, scratches, and environmental wear.

Eco-Friendly – No consumables, inks, or chemicals are required.

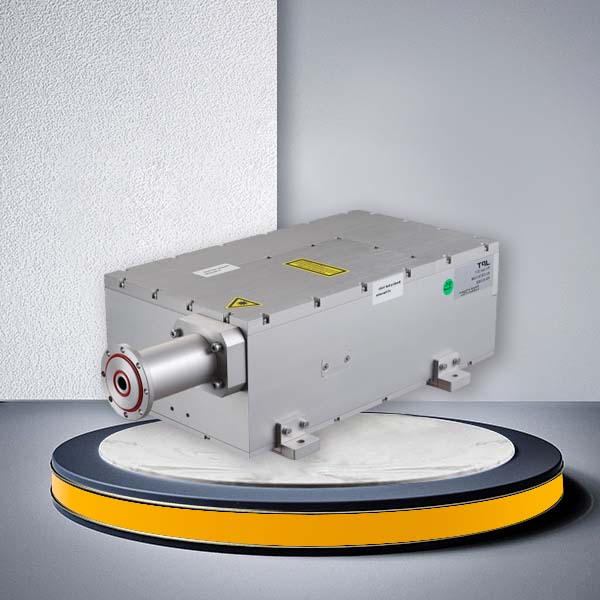

JPT UV – LARK Air Cooling

JPT UV – SEAL Water Cooling

Applications of UV Glass Laser Marking Machine

The UV glass laser marking machine is widely used in multiple industries thanks to its high adaptability and precision:

Packaging Industry – Permanent batch codes, production dates, and logos on glass bottles for beverages, cosmetics, and pharmaceuticals.

Electronics Industry – Micro engraving on glass displays, touch panels, and optical components.

Medical Industry – Permanent identification on glass labware such as syringes, test tubes, and beakers, ensuring traceability.

Decorative & Gift Industry – Custom logos, text, and patterns on trophies, awards, and glass ornaments.

How the UV Glass Laser Marking Machine Works

The UV glass laser marking machine focuses a 355 nm ultraviolet beam onto the surface of the glass. Instead of heating and melting the surface, the UV laser disrupts the molecular bonds in a process called photoablation, which removes material precisely and cleanly. This results in smooth, high-contrast markings without damaging the surrounding area.

With advanced software such as EZCAD, the operator can control engraving depth, speed, and patterns, making the process both flexible and efficient.

Advantages Over Other Methods

No Surface Damage – Non-contact process ensures the glass remains intact and smooth.

Micro-Detail Capability – Perfect for QR codes, microchips, and electronics.

Durability – Markings will not peel, fade, or wear off.

Integration with Production Lines – Can be applied for high-speed “marking on the fly” operations.

Cost-Effective – Minimal maintenance, no consumables, and long machine lifespan.

Why Invest in a UV Glass Laser Marking Machine?

For businesses seeking precision, efficiency, and compliance, the UV glass laser marking machine is the ultimate solution. It ensures products meet strict industry standards, improves brand value through permanent markings, and reduces long-term operating costs. From mass production lines to custom engraving, UV laser technology offers unmatched versatility and quality.

Conclusion

So, what tool is used to engrave glass? The clear answer is the UV glass laser marking machine. Its cold laser processing, ultra-fine engraving capability, and broad industry applications make it the most advanced choice for modern glass engraving needs.

Whether your business is in packaging, electronics, medical devices, or decorative products, UV laser technology delivers precision, durability, and efficiency to elevate your production process.